Custom Search

|

|

|

||

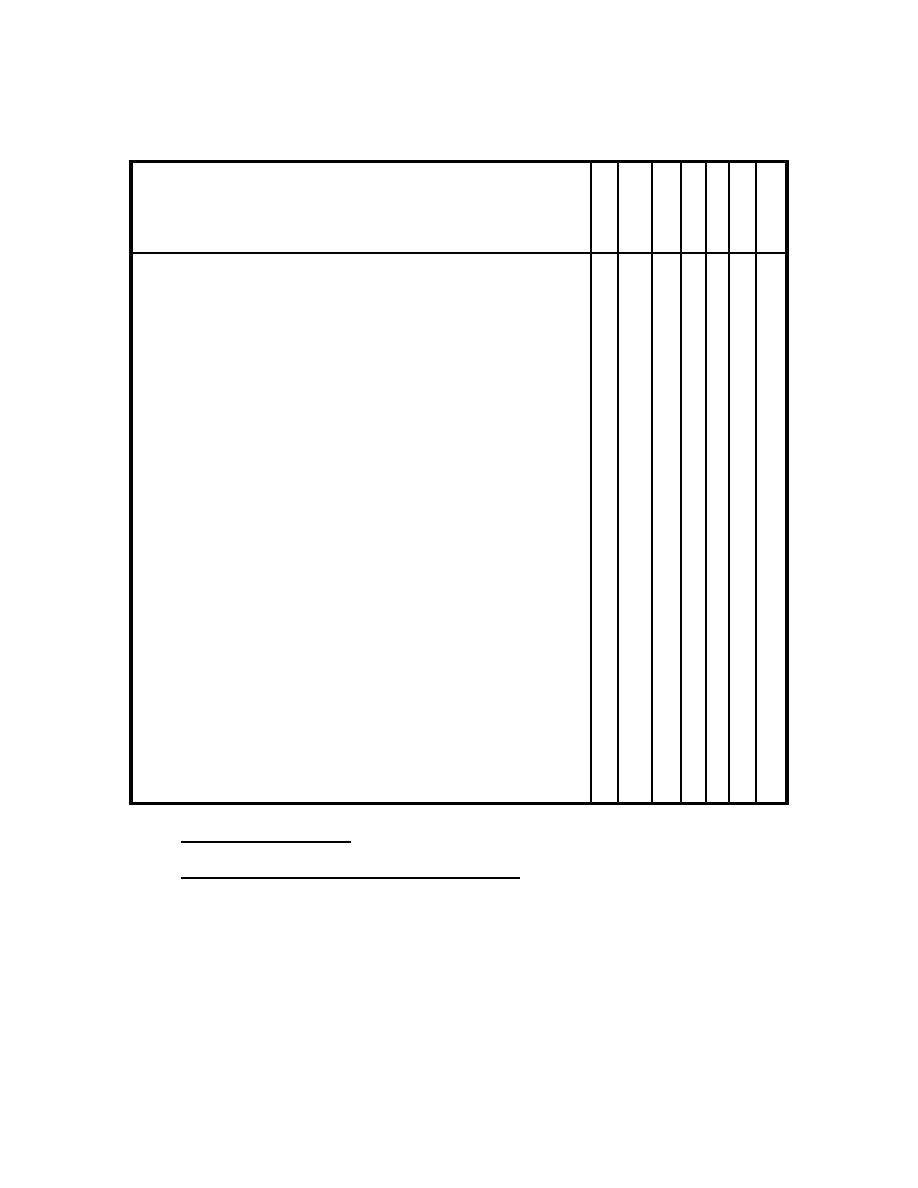

MIL-HDBK-1023/4

Table 6

Preventive Maintenance Inspection Schedule for Rotating Beacons

D W

M

B

Q

S

A

A K

T

I

T

M

N

Maintenance Requirement

I L

H

M

R

A

N

L Y

L

H

L

N

L

Y

Y

Y

Y

Y

Y

1.

Check for beacon operation and proper color sequence.

X

2.

Count rpm of beacon.

X

3.

Check telltale indicator lamp for reserve lamp status.

X

4.

Check operation of the lamp-changer.

X

5.

Check slip rings and brushes.

X

6.

Test the clutch torque.

X

7.

Check lens retainers.

X

8.

Check telltale indicator lamp.

X

9.

Check operation of relays.

X

10. Clean and polish glassware.

X

11. Check and record input voltage.

X

12. Check lamp focus and beam elevation.

X

13. Lubricate main shaft, motor, ring gear, and padlocks.

X

14. Check operation of electrical switches and contacts.

X

15. Check lightning arresters and grounding system.

X

16. Check power meter.

X

17. Check level of base.

X

18. Clean and re-grease gears.

X

19. Inspect wiring, lugs, and conduit.

X

20. Check weatherproofing and gaskets

X

5.3

Wind Cone Assemblies

5.3.1

Preventive Maintenance Inspection Procedures. To perform the PMIs contained in

Table 7 proceed as follows:

a) Daily checks

(1) Visually check to see that the lights are burning properly each night. If the

lamps burn dimly, the voltage is probably too low. If the lamps burn out too frequently, the

voltage is probably too high. The voltage should be 120 volts, 5 percent volts AC, or as

defined in the manufacturer's specifications.

(2) If a photocell is used, cover it and verify that the lights turn on.

38

|

|

|

|

||