Custom Search

|

|

|

||

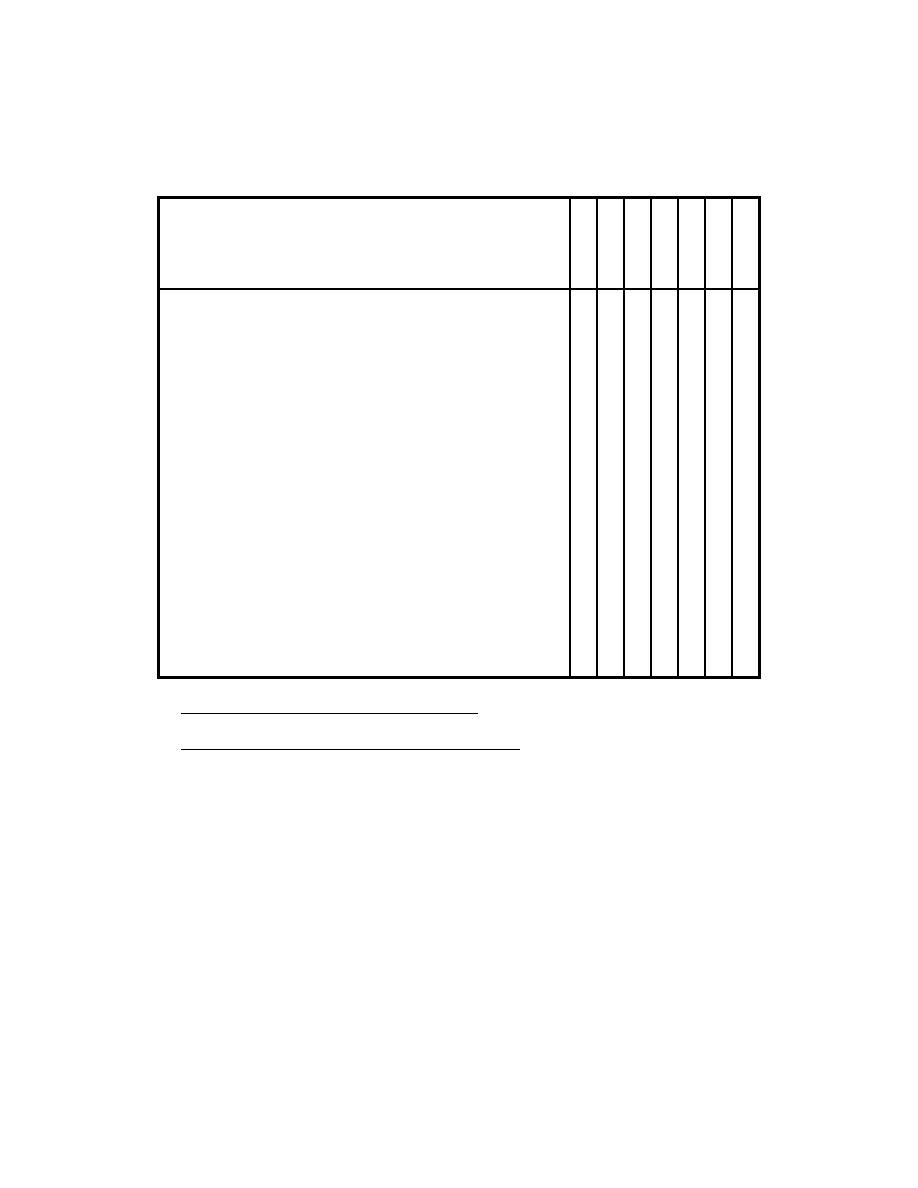

MIL-HDBK-1023/4

Table 15

Preventive Maintenance Inspection Schedule for

Hazard Beacons and Obstruction Lights

D

W

M

B

S

A

U

A

K

T

I

M

N

N

Maintenance Requirement

I

L

H

M

A

N

S

L

Y

L

H

N

L

C

Y

Y

Y

Y

Y

H

1. Check operation of lamps.

X

2. Check flash rate of hazard beacons.

X

3. Check operation of photocell.

X

4. Check insulation resistance and ground

X

5. Check wire and connections.

X

6. Check voltage at lamp socket.

X

7. Check weatherproofing of the fixture.

X

8. Check lightning protection system.

X

9. Check power meter.

10. Service lowering device and other supporting

X

hardware.

11. Check changeover relay in dual fixture.

X

12. Clean and recondition beacon.

X

13. Install new lamp after 80 percent of rated life.

X

5.10

Runway End Identification Lights (REIL)

5.10.1

Preventive Maintenance Inspection Procedures. A typical layout of the REIL System

is shown in Figure 16. To perform the PMIs contained in Table 16, proceed as follows:

a) Daily Checks. Check that lamps are operating and are flashing in proper sequence.

b) Bimonthly checks

(1) Check the controls for proper operation. Observe operation on each intensity

step.

(2) Check cleanliness of optical surfaces, both interior and exterior.

(3) Check for damage or misaligned lights.

(4) Check interlock device on door of each cabinet. Verify that shutdown occurs

when each door is opened.

(5) Check for vegetation or other obstruction around lights.

64

|

|

|

|

||