Custom Search

|

|

|

||

MIL-HDBK-1023/4

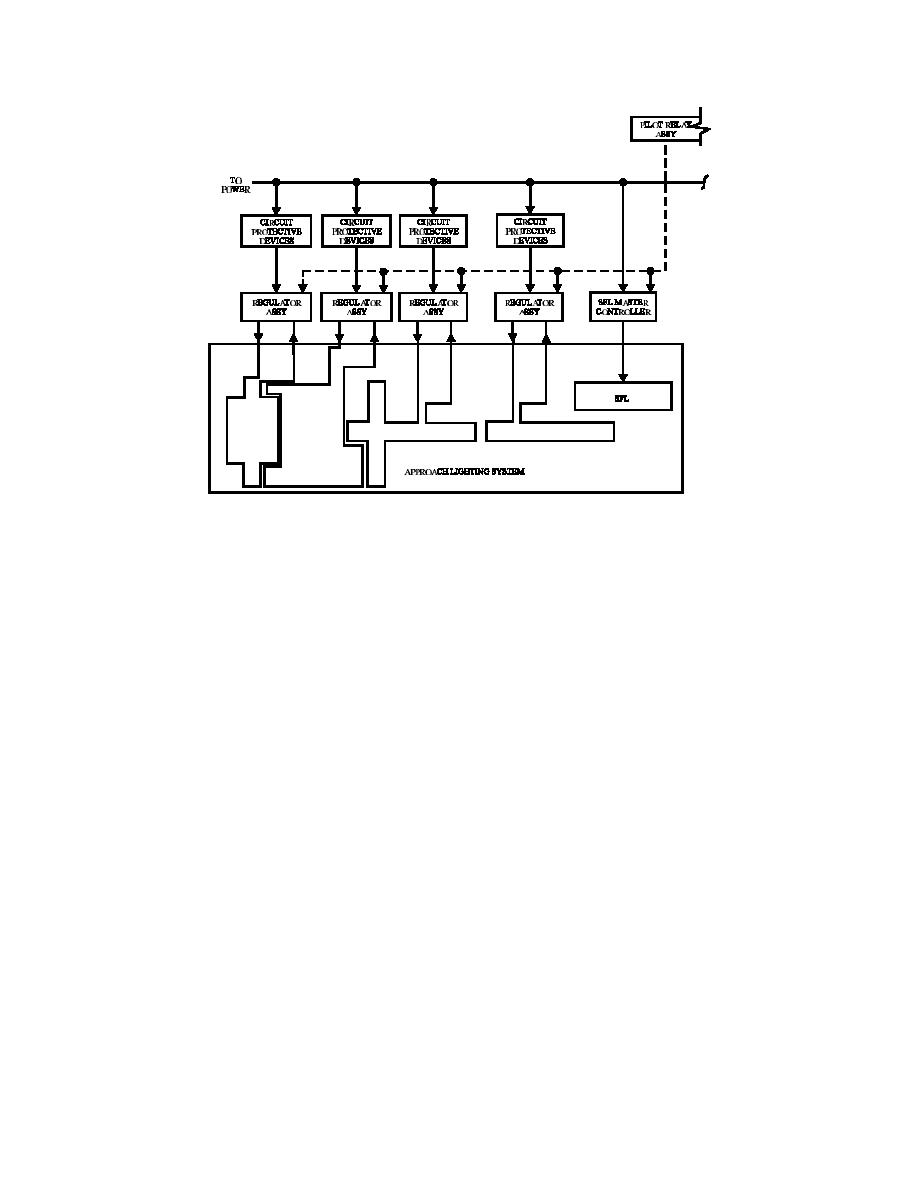

Figure 20

ALSF-2 Block Diagram

d) Semiannual checks

(1) Check light fixtures for alignment. The elevation angle settings of the lamps

differ at each light bar station. Permanently display these angles at each station to facilitate

maintenance.

(2) Check structures carefully for hidden corrosion. Pay special attention to

wood-to-wood, wood-to-steel, wood-to-earth, and steel-to-earth contacts.

(3) If used, check and adjust the photoelectric controls. Verify that the

photoelectric control is adjusted to turn the lights on at a north-sky light intensity level of 35

footcandles and to turn off at 58 footcandles. If the unit is properly adjusted, the system will

operate on the high brightness position on a relatively clear day from approximately 1/2 hour

after sunset to 1/2 hour before sunrise. Also, check the orientation of the photoelectric cell.

Orient the cell by aiming at or slightly above the northern horizon. If adjustments are necessary,

refer to the applicable manufacturer's instruction book for detailed adjustment procedures.

(4) Every 6 months, sparingly lubricate the timer cam shaft ball bearings and gear

train of the sequenced flasher position timer. Use a good grade of bearing grease and avoid

excessive amounts. Operate timer for several minutes after lubrication, then remove any loose or

excessive grease with a lint-free cloth.

e) Annual checks

(1) Check pole-top-mounted or termination switches.

(2) Check main power and control cable insulation resistance. Record reading on

the insulation resistance form. Compare current reading with previous readings to determine if

cables are deteriorating.

77

|

|

|

|

||