Custom Search

|

|

|

||

MIL-HDBK-419A

7.4.1 Contact Resistance.

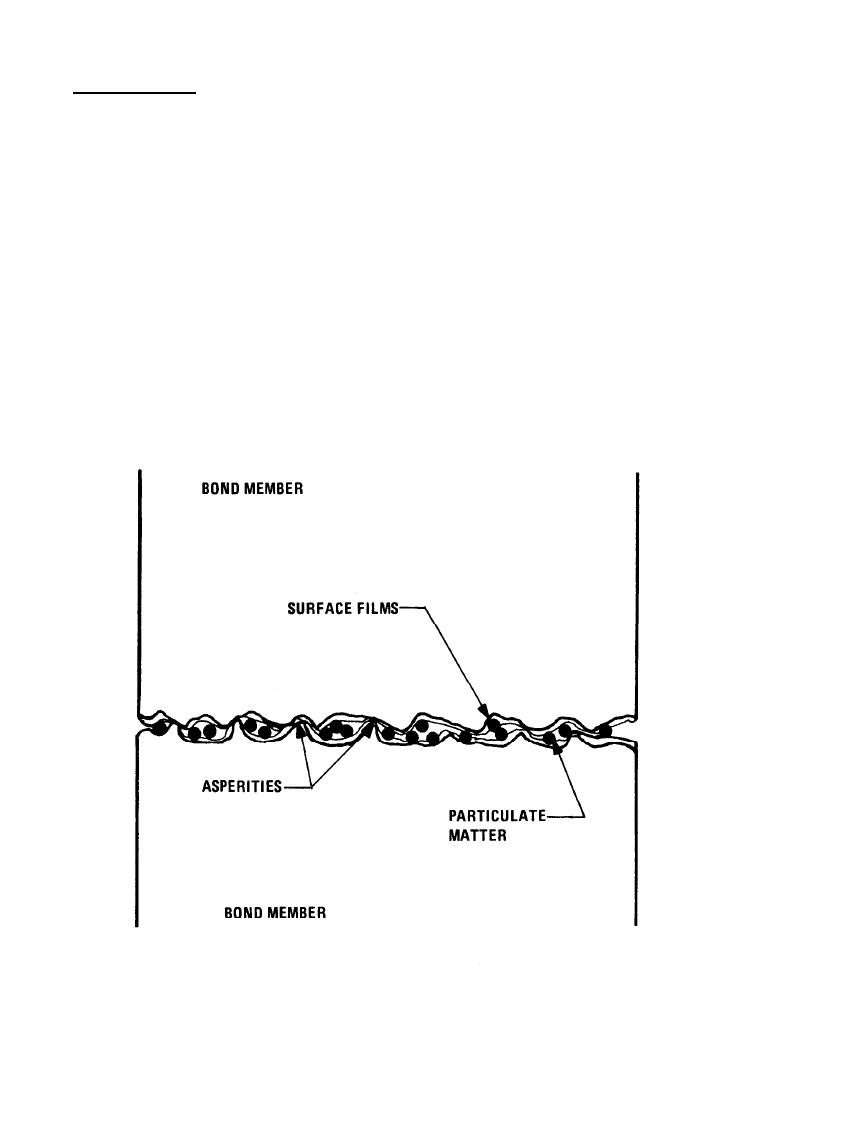

No metallic surface is perfectly smooth. In fact, surfaces consist of many peaks and valleys. Even the

smoothest commercial surfaces exhibit an RMS roughness of 0.5 to 1 millionth of an inch (7-2); the roughness

of most electrical bonding surfaces will be several orders of magnitude greater. When two such surfaces are

placed in contact, they touch only at the tips of the peaks - so called asperities. Thus the actual area of

contact for current flow is much smaller than the apparent area of metallic contact.

An exaggerated side view of the actual contact surfaces at a bond interface is shown in Figure 7-3.

Theoretically, two infinitely hard surfaces would touch at only three asperities. Typically, however, under

pressure elastic deformation and plasticity allows other asperities to come into contact. Current passes

between the surfaces only at those points where the asperities have been crushed and deformed (7-3) to

establish true metal contact. The actual area of electrical contact is equal to the sum of the individual areas

of contacting asperities. This actual area of contact can be as little as one millionth of the apparent (gross

surface) contact area (7-4).

Figure 7-3. Nature of Contact Between Bond Members

7-6

|

|

|

|

||