Custom Search

|

|

|

||

MIL-HDBK-419A

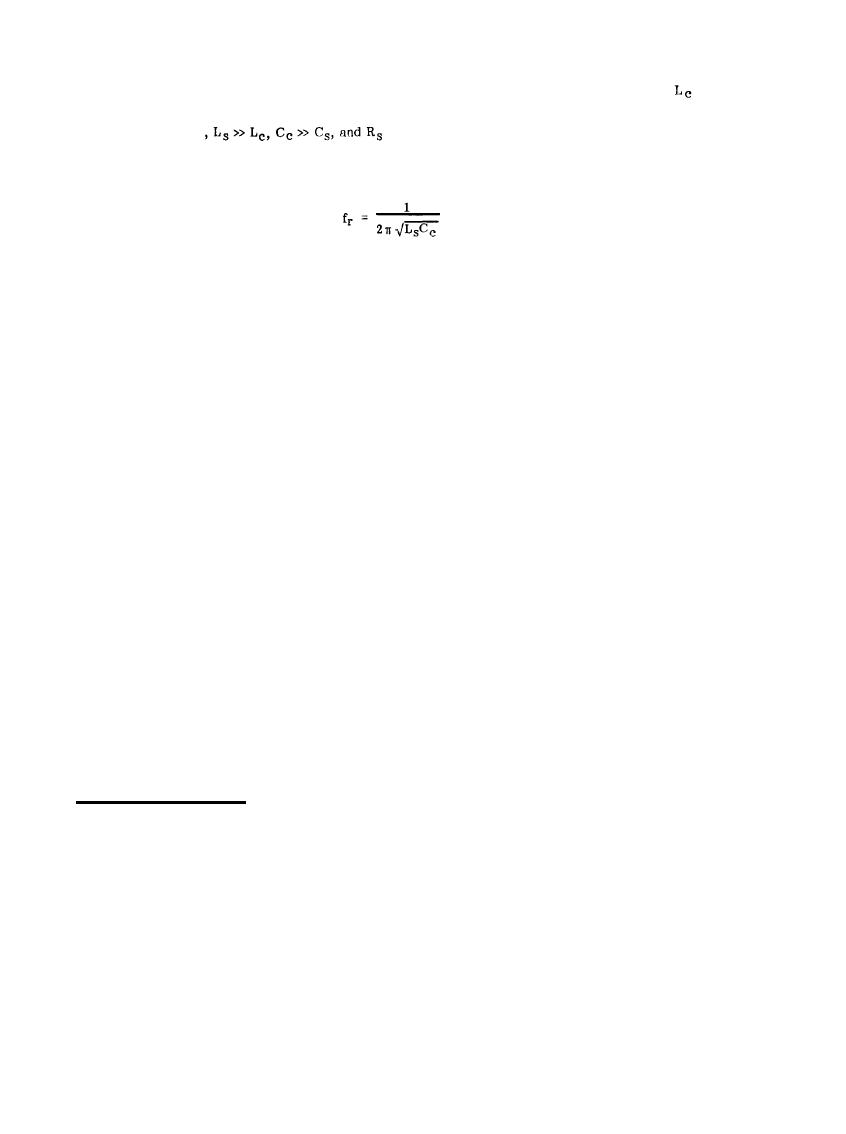

The inherent inductance of a bonded object, e.g., an equipment rack or cabinet, is represented by

and the

capacitance between the bonded members, i.e., between the equipment and its reference plane, is represented

can again be ignored. Thus, the primary (i.e., the lowest)

by Cc. In most situations

resonant frequency is given by

(7-5)

These resonances can occur at surprisingly low frequencies -- as low as 10 to 15 MHz (7-5) in typical

configurations. In the vicinity of these resonances, bonding path impedances of several hundred ohms are

common. Because of such high impedances, the strap is not effective. In fact, in these high impedance regions,

the bonded system may act as an effective antenna system which increases the pickup of the same signals which

bond straps are intended to reduce. Figures 7-15 and 7-16 show the measured effectiveness of two different

lengths of bonding straps in the reduction of the voltage induced by a radiated field on an equipment cabinet

above a ground plane. The bond effectiveness indicates the amount of voltage reduction achieved by the

addition of the bonding strap. Positive values of bonding effectiveness indicate a lowering of the induced

voltage. At frequencies near the network resonances, the induced voltages are higher with the bonding straps

than without the straps. Figures 7-15 and 7-16 show that:

at low frequencies where the reactance of the strap is low, bonding straps will provide effective

a.

bonding;

b . at frequencies where parallel resonances exist in the bonding network, straps may severely enhance

the pickup of unwanted signals and

c.

above the parallel resonant frequency, bonding straps do not contribute to the pickup of radiated

signals either positively or negatively.

In conclusion, bonding straps should be designed and used with care with special note taken to ensure that

unexpected interference conditions are not generated by the use of such straps.

7.6 SURFACE PREPARATION. To achieve an effective and reliable bond, the mating surfaces must be free

of any foreign materials, e.g., dirt, filings, preservatives, etc., and nonconducting films such as paint, anodizing,

and oxides and other metallic films. Various mechanical and chemical means can be used to remove the

different substances which may be present on the bond surfaces. After cleaning, the bond should be assembled

or joined as soon as possible to minimize recontamination of the surfaces. After completion of the joining

process, the bond region should be sealed with appropriate protective agents to prevent bond deterioration

through corrosion of the mating surfaces.

7-25

|

|

|

|

||