Custom Search

|

|

|

||

MIL-HDBK-419A

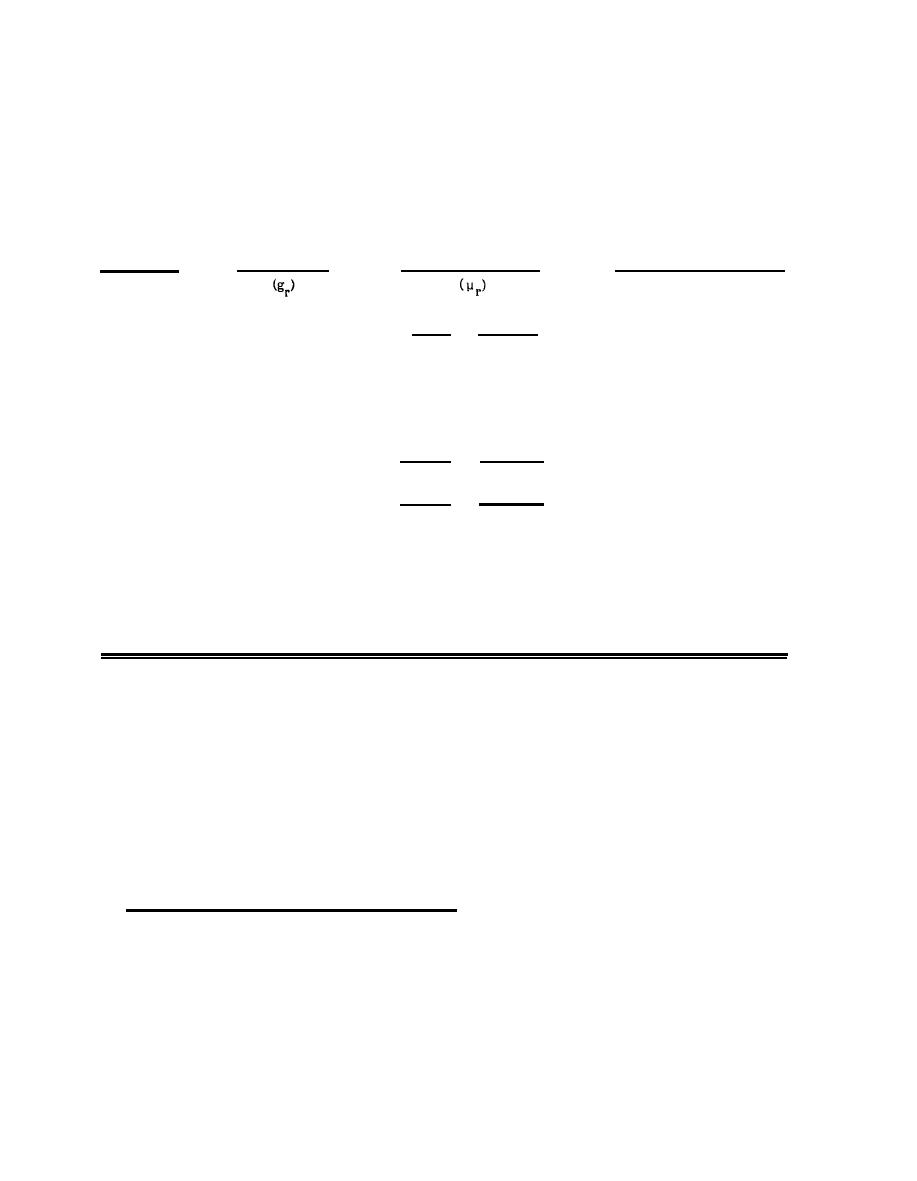

Table 1-29 (Continued)

Relative Conductivity and Relative Permeability of Common Metals

Relative

Relative

Comments

Permeability

Metal

Initial

Maximum

10% Si, 5% Al, 85% Fe

120,000

.022 - .029

Sendust

30,000

(cast)

1

Silver

1.064

0.4%-0.5% C, bal. Fe

100

50

.078 - .133

Steel

13% Mn, 1% C, 86% Fe

.025

Steel, manganese

4% Si, 96% Fe (hot rolled)

500

7,000

Steel, silicon

.034

0.1% C, 18% Cr, 8% Ni,

.019

Steel, stainless

73.9% Fe

79% Ni, 5% MO, 16% Fe

.029

100,000

1,000,000

Supermalloy

Tin

.151

1

Titanium

.036

1

.315

1

Tungsten

Zinc

.287

.1

Cover all openings required for visual access with wire screen or conductive glass (see Volume I,

e.

Section 8.5.3.2). Insure that the screen or glass is carefully bonded to the enclosure around the perimeter of the

opening.

Doors should be metal with solid, uniform contact around the edges. Wire mesh gaskets or finger

f.

stock should be provided.

For large shielded enclosures where high traffic volume is expected, consider the use of waveguide-

g.

below-cutoff hallways.

1.9 COMMON-MODE NOISE AND INSTRUMENTATION. There are several steps which can be taken during

the design and construction stages of a facility to minimize subsequent common-mode noise problems in

instrumentation, equipment, and systems. The recommended steps should be recognized as being appropriate

for interference control in general and not limited strictly to common-mode noise.

1-164

|

|

|

|

||