Custom Search

|

|

|

||

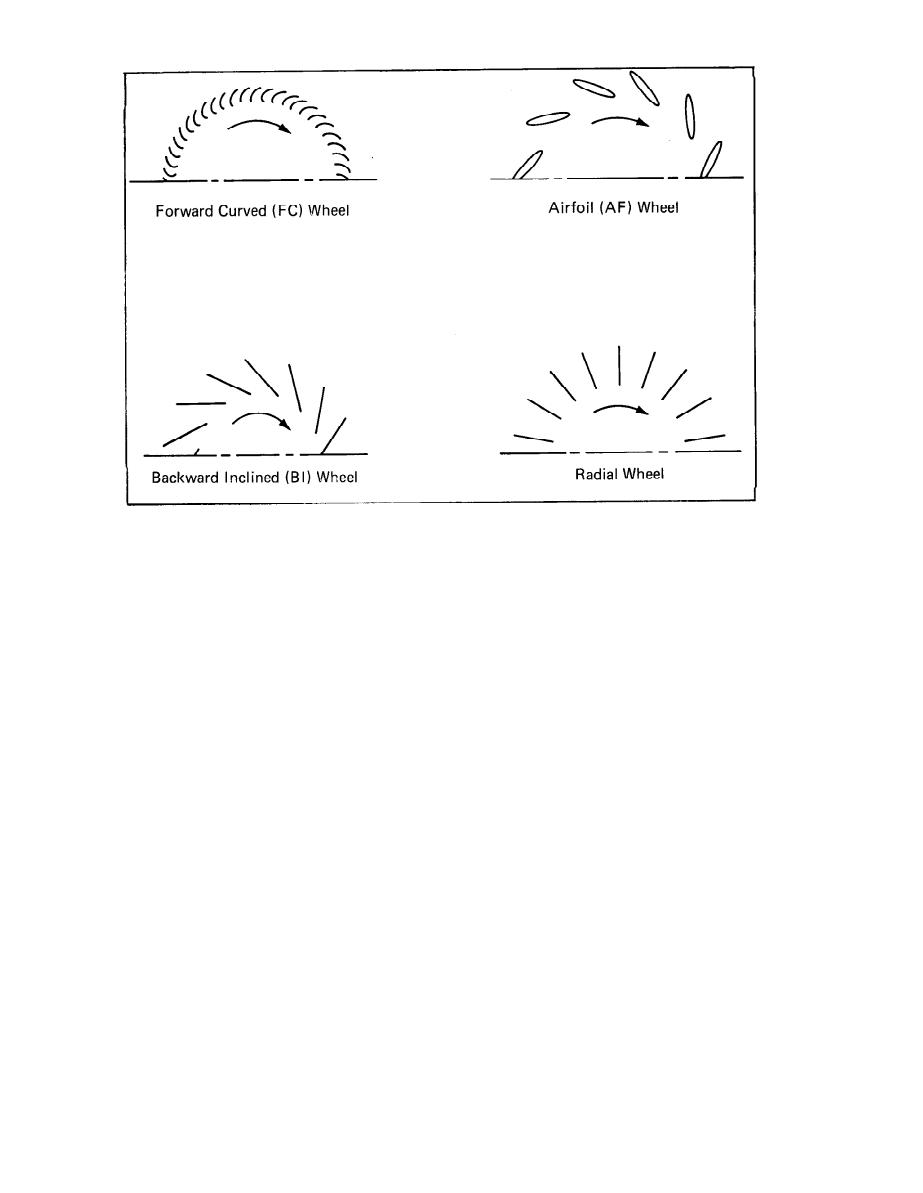

FIGURE 2-8

Impeller Types Used in Centrifugal Fans

The BI and the AF fans are more efficient, and more expensive than the

FC wheel. The rpm for these fans is much higher than for the FC fans. Note

the direction of rotation indicated. It is opposite from the usual

direction. You must be able to recognize the correct rotation direction to

be backwards when troubleshooting a new installation. A fan that is

rotating backwards will not move air in a backwards direction. It will move

air in the proper direction through the ductwork, but at a drastically

reduced flow rate.

The radial design fan blade is not generally used in normal air condi-

tioning applications. It is designed for high-strength, rugged

It is more commonly used in material handling applications.

construction.

Axial fan airflow is in the same direction as the fan shaft. Common

types of axial flow fans are:

1.

Propeller

Tubeaxial

2.

Vaneaxial

3.

The propeller fan has relatively low efficiency, inexpensive construc-

tion, and is not capable of producing static pressures in excess of a few

tenths of an inch. Propeller fans can move lots of air with a free

discharge but they have a very flat fan curve. As the static pressure

requirement increases, the cfm decreases very dramatically (Figure 2-9).

The tubeaxial fan (Figure 2-10) consists of a propeller-type fan blade

inside a cylindrical tube. The clearance between the blades and the tube is

close, increasing the efficiency. The tubeaxial is capable of developing

enough static pressure to move air through low resistance duct systems.

2-8

|

|

|

|

||