Custom Search

|

|

|

||

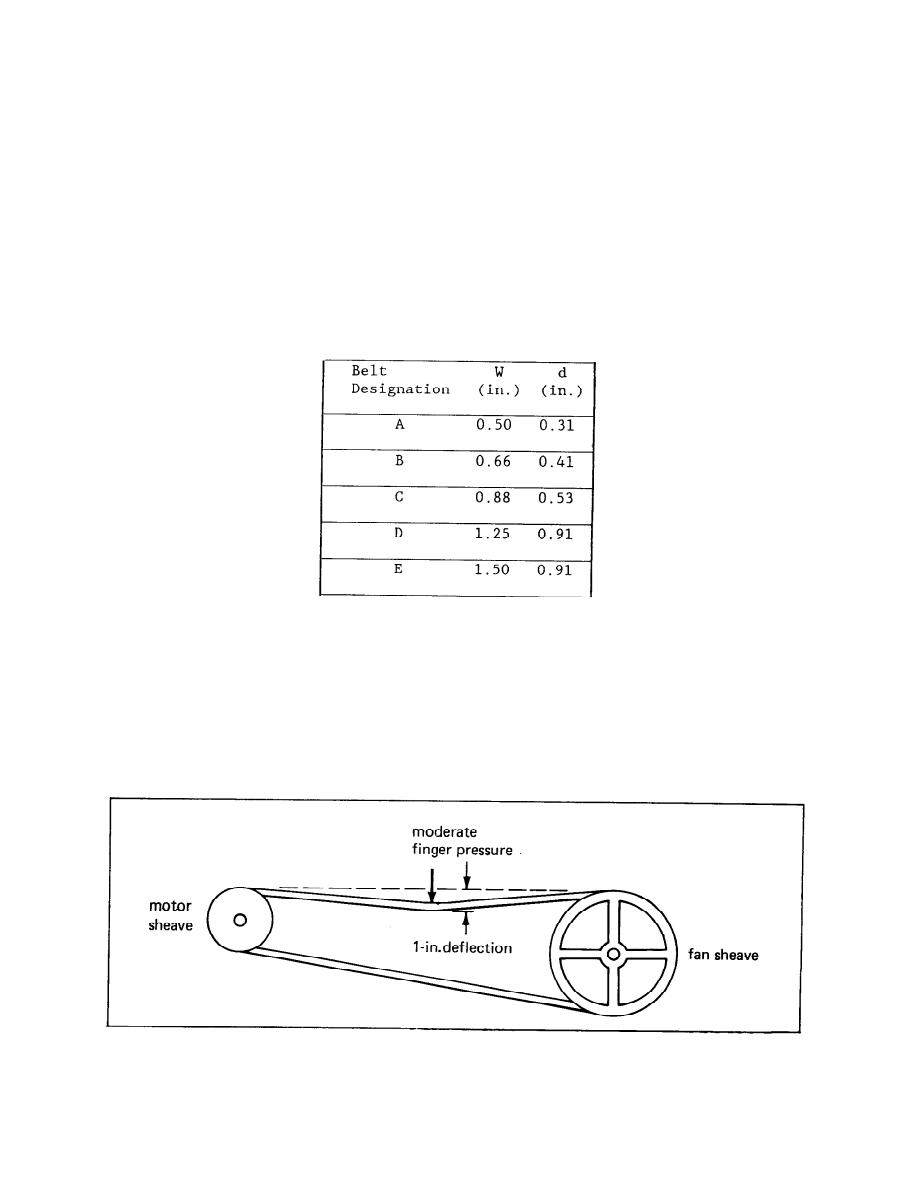

2.8 DRIVE BELTS. Drive belts, or V-belts, are designated by their

cross-sectional dimension and their length, in inches. The standard

cross-section dimensions of a belt width and depth are given in Table 2-3.

A model for a belt might be, for example, B48. This would mean that it has

a cross section of 0.66 inches width, 0.41 inches depth, and 48 inches

length. The length is at its pitch diameter. The actual outside dimension

of the belt will be an inch or two longer. When replacing a fan belt, the

new belt must be of the same cross section as the original. If it is

different, it will ride higher or lower in the groove of the sheave, and

change the effective pitch diameter of the sheave. New belts will normally

ride much higher in the sheave groove than an old belt. When the new belt

wears, its "w" dimension can become smaller, causing the belt to sink deeper

into the groove of the sheave.

TABLE 2-3

Nominal V-Belt Cross Sections

When replacing a drive belt, it is necessary to move the motor to

relieve the belt tension. After the belt is slipped over the sheaves, the

belts are retensioned. One guideline is to make it tight enough so that the

center of the span will deflect 1 inch when moderate finger pressure is

applied (Figure 2-17). This is not very exact. There are tools available

for measuring belt tension, but the required belt tension is not always

known. A simple guideline is to make the belt as loose as possible, without

it slipping on the sheave or flopping around when it is operating. A belt

that is tightened too much puts extra force on the fan and motor bearings,

and can cause bearing failure.

FIGURE 2-17

Setting Belt Tension

2-15

|

|

|

|

||