Custom Search

|

|

|

||

TM 5-683/NAVFAC MO-116/AFJMAN 32-1083

placed. Replace fuses showing signs of deterioration

magnetic fields. The test setup must be conducted

in such a way that magnetic fields created by the

such as discolored or damaged casings or pitted

test equipment, steel enclosures, or the conductors

contact surfaces. There are many types of fuses (fig

from the test equipment to the circuit breaker do

5-13) with various characteristics, some of which

not affect the test results.

are physically interchangeable. Make certain that

d. Fuses. Fuses are among the oldest types of

fuses are of the proper type and rating. Never re-

overcurrent protectors. They are simple, rugged and

place one type of fuse arbitrarily with another type

inexpensive. They sense overcurrent conditions

fuse of the same physical size simply because it fits

through the development of heat in the conducting

the fuse holder. A continuity check should also be

elements and accomplish their operation by de-

performed on replacement fuses to ensure their in-

struction of these elements. They offer both long-

tegrity. Fuses should have correct current and volt-

time and short-time short circuit protection and are

age ratings, proper time-delay or current-limiting

used widely in the protection of small motors. Main-

characteristics and an adequate interrupting rating

tenance of fuses should not be performed until all

to protect the circuit and its components Current

power sources are disconnected (fig 5-12). At that

ratings of fuses protecting transformers or motors

time, check the continuity of all fuses with an ohm-

should be selected at or near the fill load current.

meter. A reading greater than zero ohms indicates

Voltage ratings of fuses should equal or exceed their

that the fuse is blown and must be replaced. Inspect

circuit voltage. Interrupting ratings of fuses should

fuse terminals and fuse holder clips. Check that the

equal or exceed the available fault current at the

portions of the fuse making contact in the clip are

fuse holder. UL listed fuses without marked inter-

clean and bright; poor contact can cause overheat-

rupting ratings are satisfactory only on circuits

ing which results in a discoloration of the contact

where fault currents do not exceed 10,000 amperes.

surfaces. If this occurs, then the oxidized surfaces

Non-current-limiting fuses should not be used to

should be cleaned and polished. Silver-plated sur-

replace current-limiting fuses since fuse holders for

faces should not be cleaned with an abrasive mate-

UL listed current-limiting fuses are designed to re-

rial. Wiping contacts with a noncorrosive cleaning

agent is recommended. Tighten all fuse holder con-

ject fuses which are not current limiting. Fuse hold-

nections. Fuse clips should exert sufficient pressure

ers and rejection clips should never be altered or

forced to accept fuses which do not readily fit. An

to maintain good contact, which is essential for

proper fuse performance. Clips which make poor

adequate supply of spare fuses, especially those

which are uncommon, will minimize improper re-

contact should be replaced. Clip clamps are recom-

when unsatisfactory clips cannot be re-

placement.

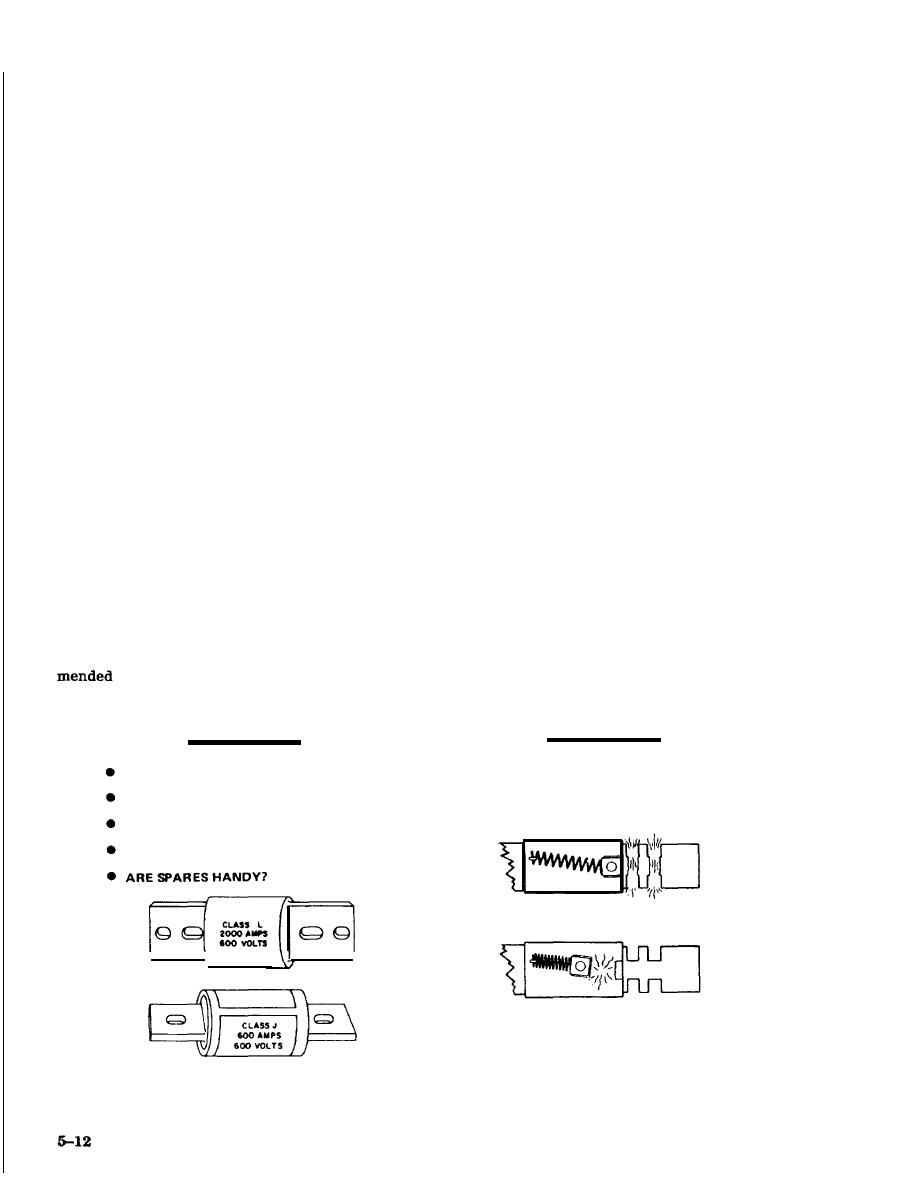

CORRECTIVE

PREVENTIVE

MAINTENANCE

MAINTENANCE

q TEST FOR CONTINUITY, SINGLE PHASING

IS FUSE TIGHT IN CIRCUIT?

q WHAT OPENED FUSE?

ARE FUSE AND HOLDERS CLEAN AND DRY?

-- SHORT?

OVERHEATING?

ARE RIGHT TYPE AND SIZE IN CIRCUIT?

--

OVERLOAD?

--

HIGH TEMPERATURE DERATING?

q REPLACE WITH RIGHT TYPE AND SIZE.

Figure 5-12. Fuse maintenance practices.

|

|

|

|

||