Custom Search

|

|

|

||

TM 5-683/NAVFAC MO-116/AFJMAN 32-1083

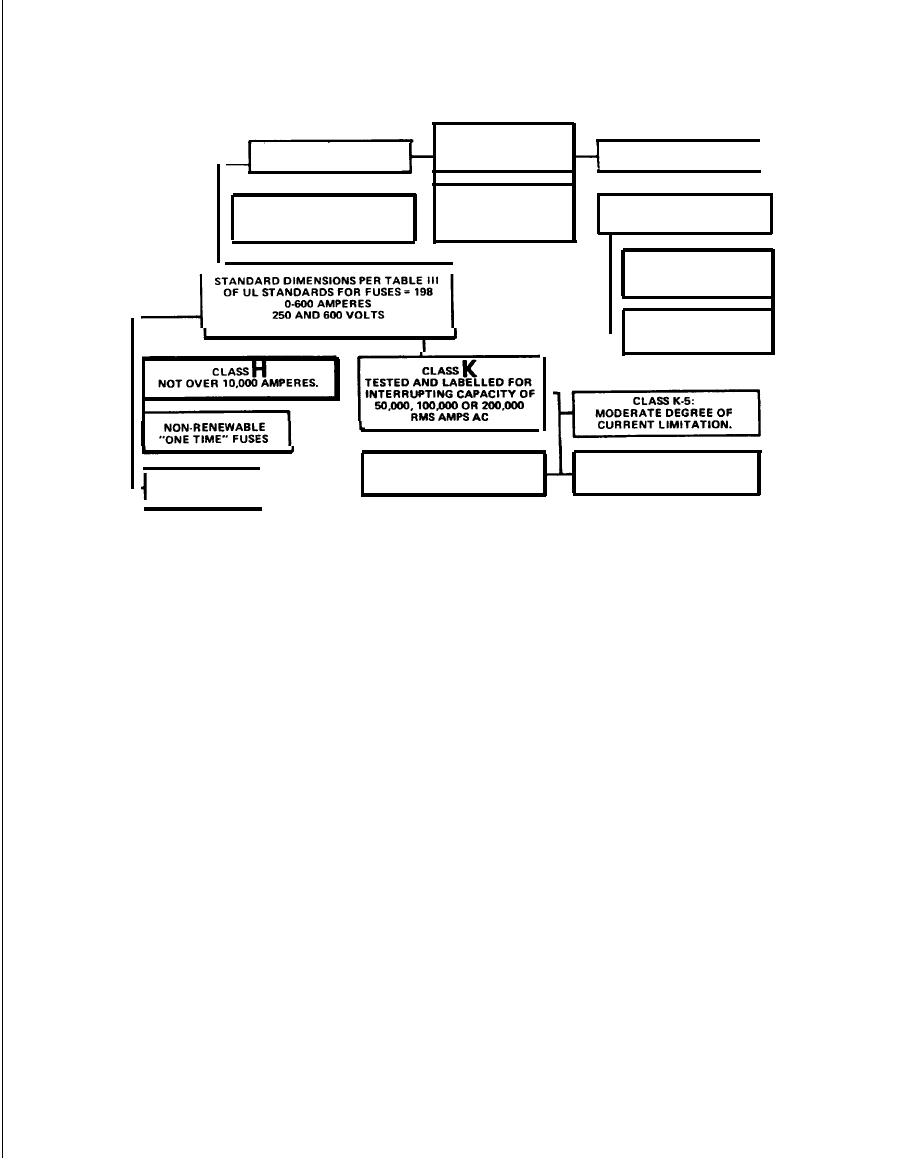

CARTRIDGE FUSES

0-600 v.

NON CURRENT LIMITING

CURRENT LIMITING

1

I

I

I

r

G

TESTED AND UL LISTED

300 VOLTS

"MISCELLANEOUS"

CLASS

"600 VOLTS OR LESS"

SPECIAL DIMENSIONS

MIDGET DIMENSION, ETC.

1

J

r

CLASS

0-600 AMPS.

1

100,000 OR 2OO,OOO/AC

L

CLASS

601-6000 AMPS

100,000 OR 200,00/AC

CLASS K-9:

CLASS K-1 :

FAIR DEGREE OF

HIGH DEGREE OF

RENEWABLE

CURRENT LIMITATION.

CURRENT LIMITATION.

LINK FUSES

I

Figure 5-13. Underwriters' Laboratories cartridge fuse classification.

sized and the line current and ambient temperature

e. Thermal overloads. Thermal overload relays

are normal, then check the relays. The relays

contained in starters provide more precise motor

should be tested and replaced if required. Unfortu-

protection against overloads and momentary surges

nately, the overload relays that serve as safety

than fuses or circuit breakers. However, they do not

valves to protect the motors from burnouts due to

provide short circuit protection. Relays themselves

faults and overloads, sometimes fail to respond

require little maintenance other than occasional

properly. For example, aging and inactivity followed

testing to ensure that they are operational. Thermal

by metal fatigue in some relay types may result in a

overloads should be checked and resized whenever

failure to operate under conditions of overload. Pe-

the motor is replaced to adequately protect the mo-

riodic testing of the relays under load conditions,

tor. The relays are controlled by heater elements (fig

checking the tightness of all overload connections

5-14) which are in series with the motor current.

and inspecting for contact overheating and cleanli-

The size of the heater must match the motor being

ness forms an important part of a good motor con-

protected. Be especially careful if the motor has

trol maintenance program. Suitable test instru-

been oversized to compensate for lower load current

ments are available that provide a dummy load to

with lower rated heaters to cause tripping on loss of

the relay and measure the time interval required to

one phase (single phasing). It often happens that

open the contacts. Their use is highly recom-

the wrong size heaters are installed. If the heater is

mended, especially on relays for motors that serve

too small, the overload relays act to take the motor

critical loads; e.g., motors driving air conditioners

off line unnecessarily. If too large, the motor will

which are used for communication or data process-

operate without proper protection and could be

ing equipment, or motors on production lines. For

damaged from overload. If the relays frequently op-

erate to take the motor off line, the heaters should

most applications, testing of motor overload relays

be checked first. If the heaters are properly sized

should be conducted every 2 years. Regular testing

of thermal overload motor relays is a recommended

(about 120 percent of motor full load current) and

there are no unusual temperature conditions, then

procedure for all installations. Overload relays em-

check the motor current. If the motor current is

ploy a thermal element designed to interpret an

higher than the nameplate rating by a margin suf-

overheating condition in the motor winding by con-

ficient to exceed the heater rating, then the relay is

verting the current in the motor leads to heat in the

operating properly, and the motor is either over-

overload relay element. As the heat in the element

loaded or in fault, therefore, check the motor. Do not

approaches a predetemnined value, the control cir-

put in larger heaters. If however, the motor stops

cuit to the magnetic contactor holding coil is inter-

frequently even though the heaters are correctly

rupted and the motor branch circuit is opened. The

5-13

|

|

|

|

||