Custom Search

|

|

|

||

TM 5-683/NAVFAC MO-116/AFJMAN 32-1083

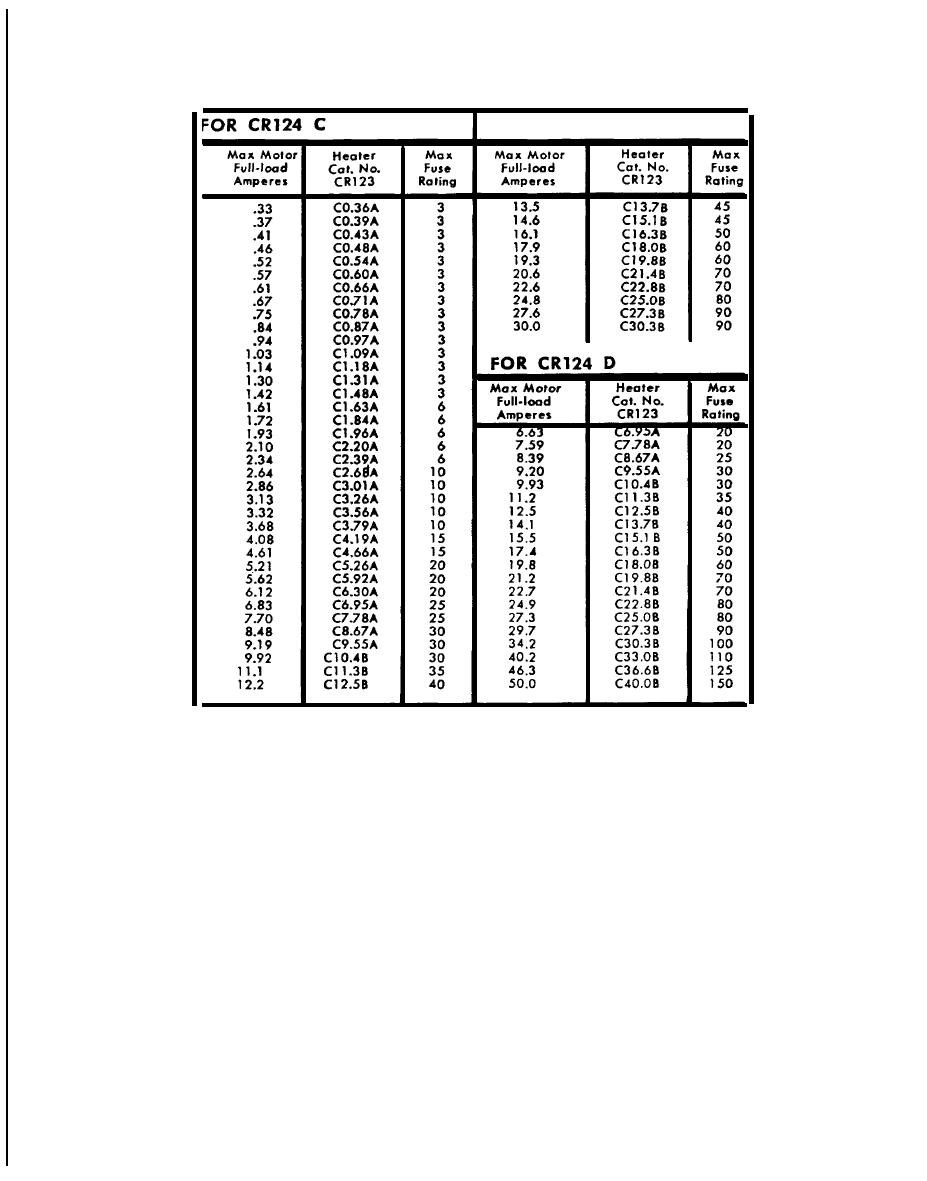

Figure 5-15. Typical heater selection table for thermal overload device.

coil than it is to attempt repairs. Coils will operate

they should be dried out by spraying a contact

efficiently at 85 to 110 percent of rated voltage.

cleaning chemical on the coil or by heating the coil

in an oven at 110 degrees C to 125 degrees C. If it is

Higher voltages shorten life and lower voltages may

necessary to varnish coils, use only an approved

result in failure to close the contacts completely.

insulating treatment applied while the coils are still

This could result in welded contacts. Coil burnout

warm from baking. These instructions on drying

also could occur if the contactor fails to close prop-

erly either from being blocked or by low voltage. In

and varnishing coils do not apply to the newer en-

either case, the current flowing through the coil is

capsulated types.

larger than rated because of the larger air gap in

5-4. Preventive maintenance and trouble-

the magnetic circuit. Maintenance consists of clean-

shooting guide.

ing out accumulated dust and grease, if any, and

Table 5-1 outlines typical preventive maintenance

inspecting the coil to see that it is of proper rating

and operates properly. When handling coils, do not

for a motor control. Table 5-2 lists troubleshooting

pick the coil up by its leads. If coils become wet,

and corrective maintenance practices.

5-15

|

|

|

|

||