Custom Search

|

|

|

||

TM 5-683/NAVFAC MO-116/AFJMAN 32-1083

Table 14-1. Interpreting insulation resistance test results.

WHAT TO DO

CONDITION

No cause for concern.

1. Fair to high values and well-

maintained.

Locate and remedy the cause and check

2. Fair to high values, but

the downward trend

showing a constant tendency

towards lower values.

Condition is probably all right, but

3. Low but well-maintained.

cause of low values should be checked.

Clean, dry-out, or otherwise raise the

4. So low as to be unsafe.

values before placing equipment in

service (test wet equipment while

drying out).

5. Fair or high values,

Make tests at frequent intervals until

previously well-maintained,

the cause of low values is located and

but showing sudden lowering.

remedied; or until the values have

become steady at a lower level but safe

for operation; or until values become

so low that it is unsafe to keep the

equipment in operation.

to be applied to each particular relay, and the test

points. This data is often furnished on a time-

current characteristic curve of a coordination study.

(4) A test instrument should be available as

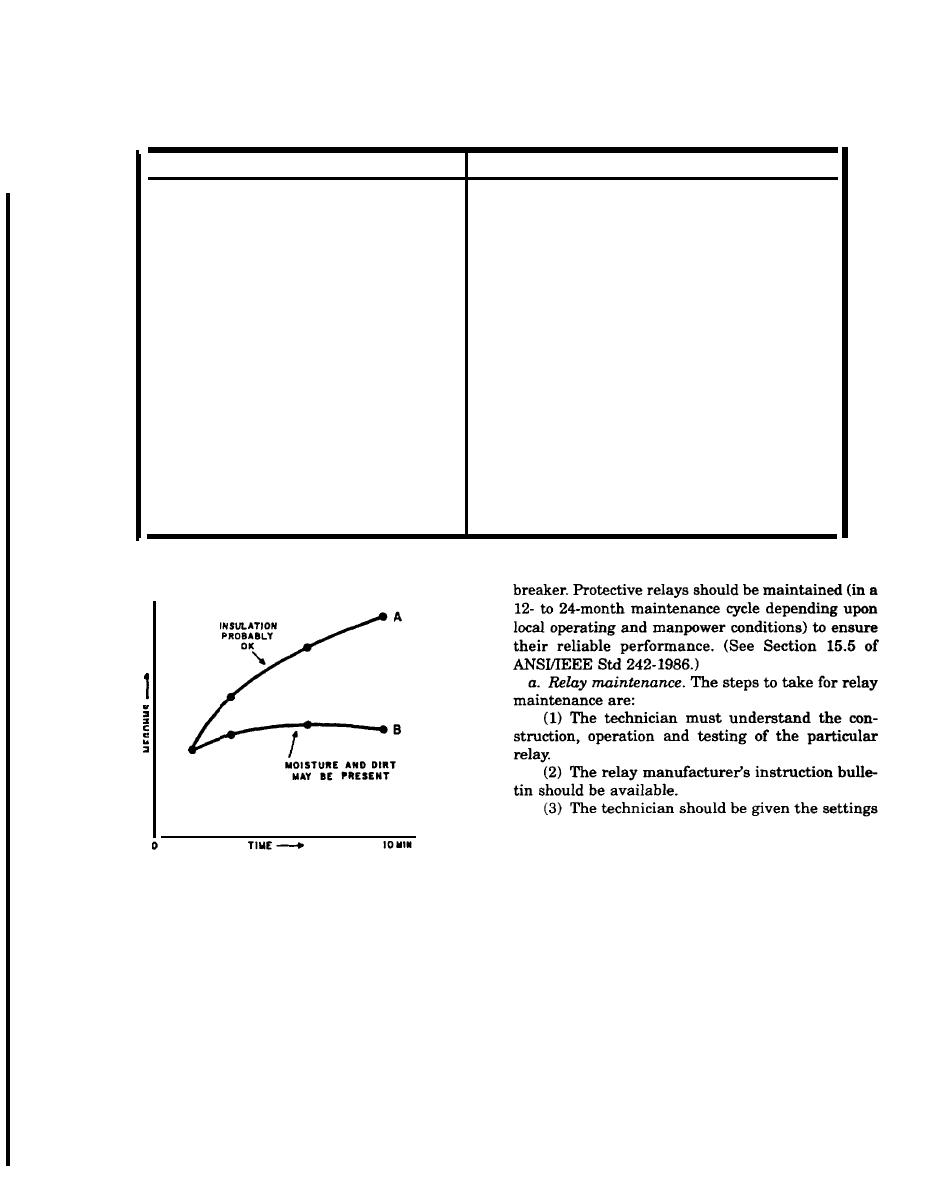

Figure14-3. Typical curves showing dielectri absorption effecting

recommended by the manufacturer.

a time-resistance or double-mading test.

(5) Most protective relays can be isolated for

testing while the electrical system is in norma op-

14-3. Protective relay testing.

eration. However, an operation of the breaker is

Protective relays are used to detect and isolate sys-

required to ascertain that the operation of the relay

tem abnormalities with minimum disturbance to the

contacts will trigger the intended reaction, such as

rest of the electrical distribution system. The more

to trip the associated circuit breaker.

common protective relays are the electro-mechanical

b. The tests to be performed are determined by

types. In them, a mechanical element, such as an

the relay to be tested. For electro-mechanical re-

induction disk or magnetic plunger, moves in re-

lays, inspection, testing and adjustment are recom-

sponse to an abnormal change in a parameter of the

mended.

eletrical system. This movement causes a contact in

(1) Inspection. Each relay should be removed

the control circuit to operate, tripping the circuit

from its case for a thorough inspection and cleaning.

14-3

|

|

|

|

||