Custom Search

|

|

|

||

TM 5-684/NAVFAC MO-200/AFJMAN 32-1082

points for boring to determine the extent of any

soft and moist, but not decayed, if preservative is

internal decay above ground.

present and the wood fibers are strong.

b. Test boring. Whenever there is reason to sus-

__

pect possible internal decay above or below the

the preservative will be plainly visible, especially if

ground line, the pole should be bored with an incre-

it is creosote. In good original treatment, it extends

ment borer as shown in figure 4-5. It is usually not

the depth of the sapwood (table 4-l shows sapwood

necessary in cedar poles due to their decay resistant

thickness). Some borings will show a heavy absorp-

tion of preservative, while in others it may appear

heartwood.

in bands, giving the core a striped appearance. (An-

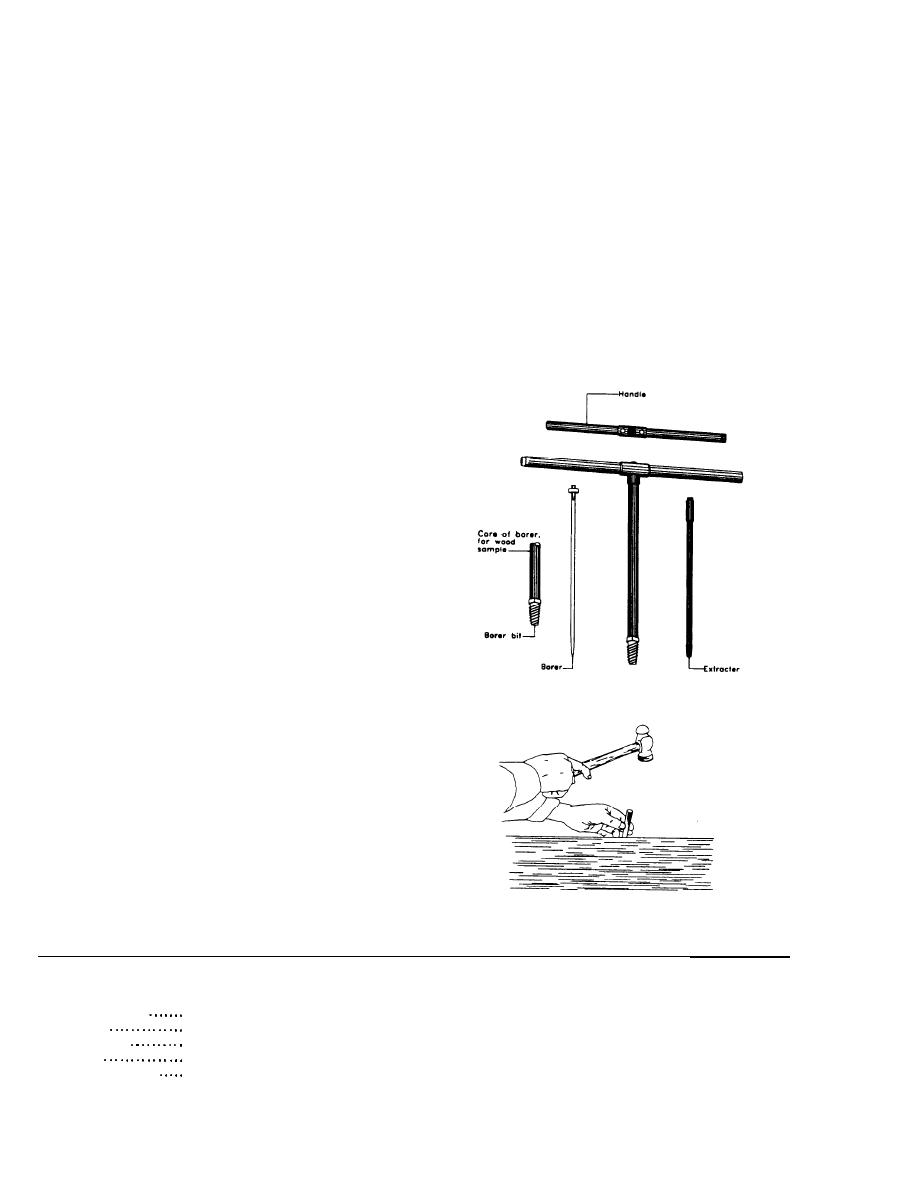

(1) Increment borer. An increment borer con-

nual growth rings comprise hard dark summerwood

sists of three parts-the borer, the extractor, and

and softer, sometimes spongy, springwood. `Usually

the handle, which also serves as a receptacle for the

the summerwood absorbs more preservative in the

other two parts when not in use. The tool is made of

timber species that are suitable for poles). In poles

the highest-quality steel to withstand the force ap-

treated with pentachlorophenol (penta) solution,

plied, though the borer has a cutting edge which

the oil carrier may not be visible, even though the

must be protected from abuse. When boring below

penta itself is present in sufficient amount.

the ground line, the pole surface at the spot bored

should be thoroughly cleaned of soil and grit by

shaving or brushing. Bore toward the center of the

pole, applying steady pressure to start, and in as

nearly a horizontal line as possible. If any slant is

necessary, it should always be upward to prevent

any later water accumulation. The core is removed

with the extractor by backing the borer a half turn

after the extractor is shoved in, so as to break off

the core before withdrawal.

(2) Plugging bored holes. All bored holes must

be plugged by hammering in a tight-fitting treated

wood plug as shown in figure 4-6, regardless of

whether the pole needs to be replaced. Habitually

and promptly drive a plug in each hole before boring

another or before proceeding with other work. Oth-

erwise, a bored hole may be overlooked, opening the

way for future internal decay. The plugs, made of

doweling, may be obtained from most pole suppli-

Figure 4-5. The increment borer

ers. Those pointed on one end are preferable but not

required. They should be 3 or 4 inches (80 to 100

millimeters) long with a diameter l/32 inch (0.8

millimeters) larger than the hole bored to provide a

snug fit. The borer, an adequate supply of plugs,

and a hammer should be kept together as a kit.

(3) Evaluating test borings. The extracted core

should be carefully examined for wood integrity or

evidence of decay, extent of any decay pocket, and

the amount of original preservative in the wood.

Decay will be evidenced by crumbly wood in part of

the core. If a pole is badly decayed, a core may not

be withdrawn intact. Borings may sometimes be

Figure 4-6. Sealing a test hole with a treated wooden plug

Table 4-l. Sapwood thickness in poles

Species

Sapwood thickness

Sapwood thickness

Natural heartwood

(inches)

(millimeters)

decay resistance

to

1.25

Western red cedar

0.5

13

to

32

High

0.75

Douglas fir

to

2.5

19

64

Moderate

to

0.5

Western larch

to

1.5

13

38

Moderate

to

0.75

Jack pine.

to

2.0

19

to

51

Moderate

2.0

Red (Norway) pine..

to

4.0

51

102

to

Moderate

4-8

|

|

|

|

||