Custom Search

|

|

|

||

TM 5-684/NAVFAC MO-200/AFJMAN 32-1082

OF LEAD

WIRE

STAPLE

T E N SIO N S T R A N D

(CUT

INSTALLATION)

360 K

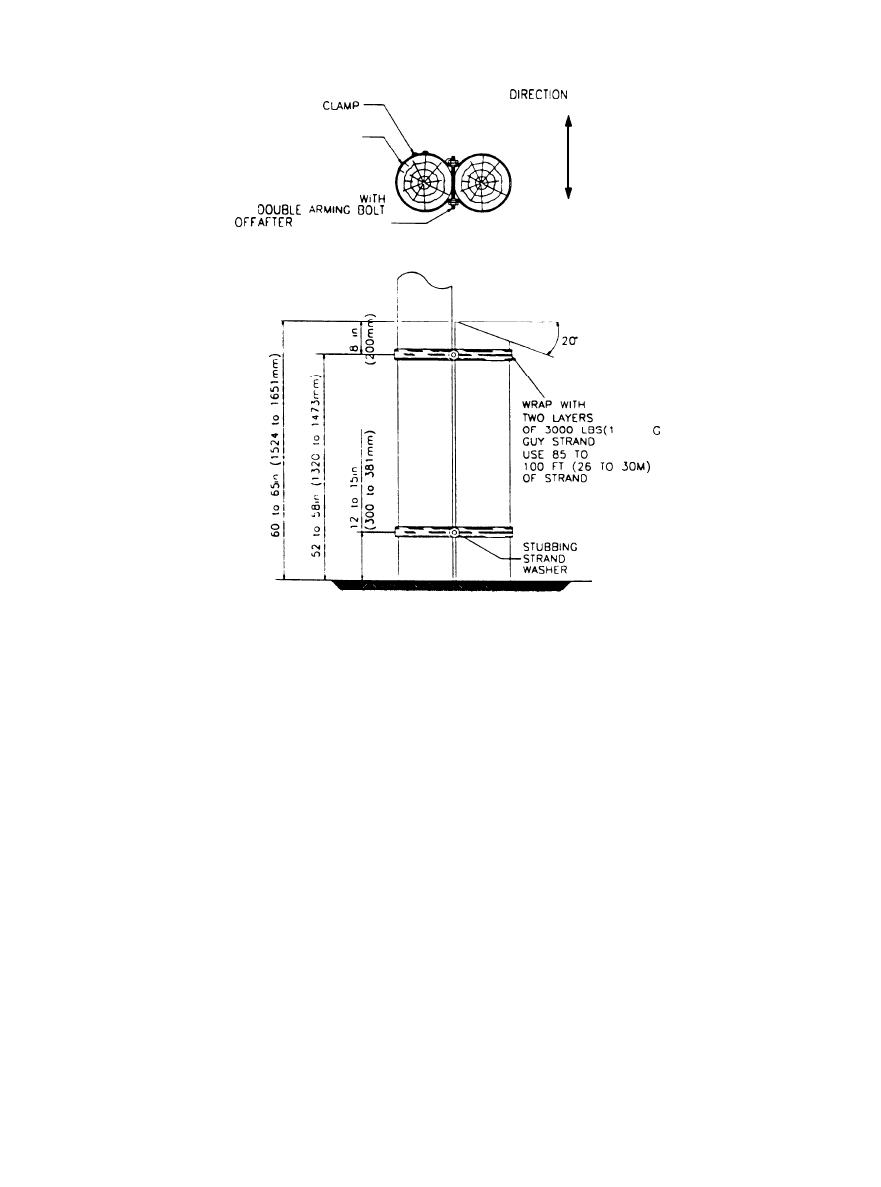

Figure 4-7. Wood stub pole

c. Compound set methods. There are a number of

also contain an approved preservative additive that

compound set methods. Engineering evaluation

migrates to the outside surfaces of the pole under a

should select the appropriate method.

time-delay release action.

(1) Compound. The simplest method requires a

(3) Compound, rebars, and collar. This method

compound (mixed in a completely self-contained

requires a 2-foot (0.6-meter) deep trench to be exca-

mixing unit) which fills a hole slightly larger than

vated around the pole and several 4-foot (1.2-meter)

the pole diameter. It is suitable also for straighten-

long rebars to be stapled about the pole. An inert 3

to 4 foot (0.9 to 1.2 meter) collar descends to about 2

ing poles.

(2) Compound and casing. The decaying region

feet (0.6 meters) below the ground line and is filled

by funnel with hand or electric mixed epoxy-resin

is first treated with a liquid fumigant. A split-metal

compound. Periodic tamping is needed to ensure

casing is driven below grade by rotary-driven equip-

proper compound setting. The trench is then

ment. The casing is filled with an epoxy-aggregate

backfilled after the compound has cured.

for stabilization and extra strength. The filler may

Section V - CROSSARMS, BRACES, AND PLATFORMS

4-19. Pole crossarms.

ments should be kept tight. If preservative treat-

ment is applied to the pole, the crossarms should

All facility crossarms are fully treated and are usu-

also be treated. Crossarms should be inspected vi-

ally of Douglas fir or yellow pine. The length and

sually from the ground whenever a pole is in-

cross section of an arm is determined by the brace

spected. If the pole inspection indicates the pole

and strength requirements. Properly installed cross-

may be climbed, a closer inspection should be made.

arms require little maintenance. Crossarms can de-

a. Decay. Crossarm decay usually starts at pin-

cay; aging can cause separations such as checks or

holes and can best be detected with a probe, if war-

shakes; lightning can splinter crossarms; or they

ranted by visual inspection. Probe the arm enough

may twist or bend by overload. These occurrences

may necessitate replacement. All crossarm attach-

to determine the extent of the decay.

4-11

|

|

|

|

||