Custom Search

|

|

|

||

TM 5-684/NAVFAC MO-200/AFJMAN 32-1082

Table 4-3. Tie wire requirements

relate directly to insulator classes. An understand-

ing of the relations between insulator classes and

Tie wire

Conductor

insulation level requirements is helpful in under-

Copper AWG.

Soft-drawn copper AWG

standing why each facility should have a recognized

6 .................................

8

insulation level (class) for its various on-site distri-

4 and 2

6

bution levels if they vary from requirements given

1 through

4

and larger

2

in table 4-4.

AAC,AAAC,orACSRAWG . . . . . . . . .

AWG

a. Code requirements. The NESC spells out dry

Any size.

flashover requirements up to 230 kV These should

be considered a minimum, even though a qualified

conductor and likewise, a covered tie wire should

engineering study could permit lower insulation

always be used on a covered conductor. A loose or

levels. The NESC requires the use of insulators

improper tie wire may be a source of radio interfer-

with higher dry flashover levels where severe light-

ence.

ning, high atmospheric contamination, or other un-

4-47. Pole line insulator class requirements.

favorable conditions exist. The NESC preparers rec-

ognized that dry flashover may not be the best test,

Insulator ratings are not specified by voltage but by

but it has been used for many years with reasonable

ANSI C29 insulator classes. Manufacturers may in-

success. The desirability of using wet flashover as a

dicate nominal line-voltage values but the NESC

basis has been recognized, but no consensus agree-

does not recognize voltage levels. Insulation level

ment has been reached.

requirements are given in the NESC and do not

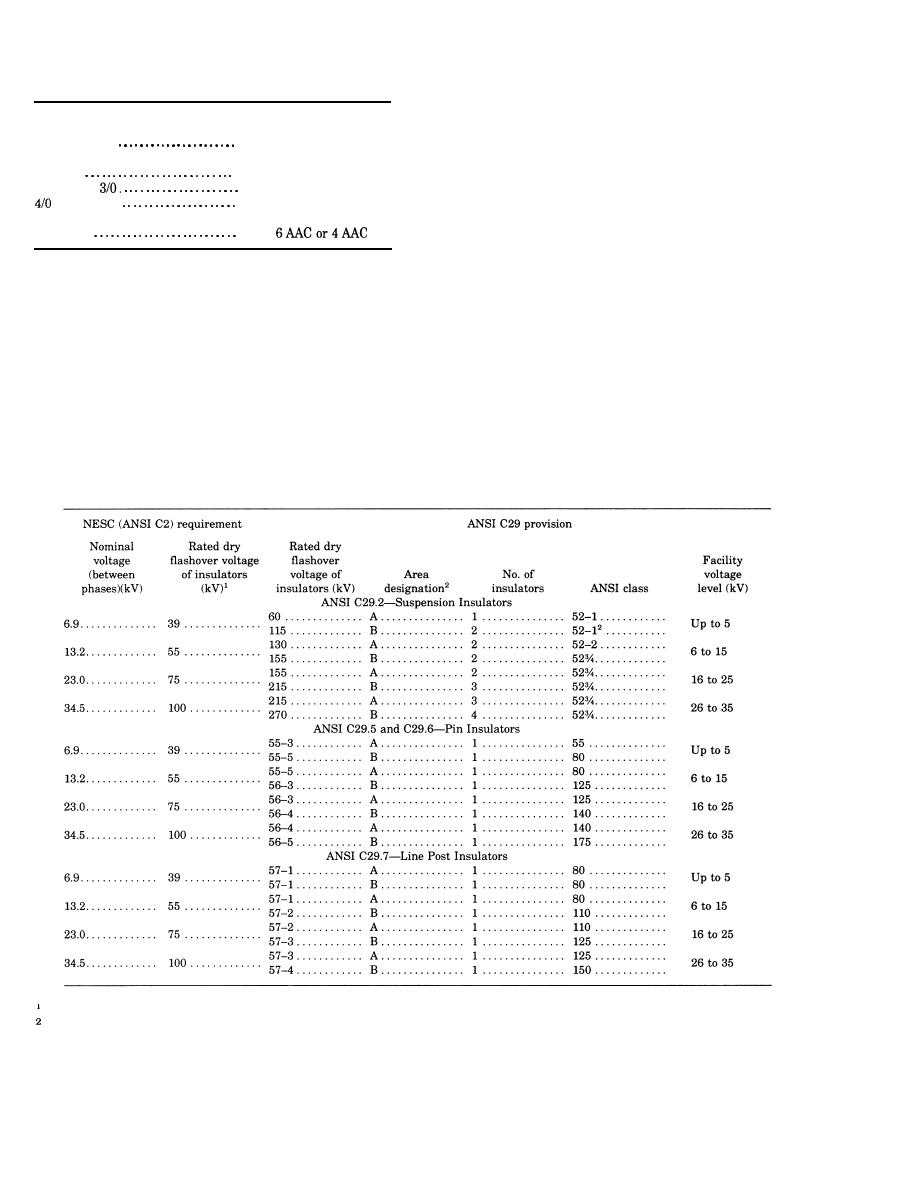

Table 4-4. Relation of the NESC voltage levels to ANSI C29 class ratings

NESC (ANSI C2) requirement

ANSI C29 provision

Nominal

Rated dry

Rated dry

Facility

flashover voltage

flashover

voltage

(between

of insulators

voltage of

Area

No. of

voltage

insulators

designation 2

insulators

ANSI class

level

phases)(kV)

ANSI

Insulators

60.. . . . . . . . . . . . . A

...............

............... 52-l............

6.9

39

up to 5

115.. ........... B

. . . . . . . . . . . . . . . 2 ...............

.........

130 ............. A

. . . . . . . . . . . . . . . 2 ............... 52-2 ............

13.2 .............

55 ..............

6 to 15

............. B

...............

2

...............

.............

A

............... 2

...............

.............

23.0 .............

75.. ............

16 to 25

.............

............... 3

...............

.............

A ............... 3

...............

.............

26 to 35

34.5 .............

100 .............

.............

............... 4

...............

.............

ANSI C29.5 and

Insulators

A...............

1 . . . . . . . . . . . . . . . 55 . . . . . . . . . . . . . .

up to 5

B...............

1 . . . . . . . . . . . . . . . 80 . . . . . . . . . . . . . .

55-5 ............ A . . . . . . . . . . . . . . .

1 . . . . . . . . . . . . . . . 80.. ............

6 to 15

13.2 .............

55 ..............

............ B ...............

1 ............... 125 .............

56-3 ............ A . . . . . . . . . . . . . . .

1 . . . . . . . . . . . . . . . 125 .............

16 to 25

75 ..............

23.0 .............

............ B ...............

1 ............... 140 .............

A ...............

1

140 .............

26 to 35

34.5 .............

100 .............

............

...............

1 ............... 175 .............

ANSI

Post Insulators

A

. . . . . . . . . . . . . . . 1 ...............

57-1 ............

80.. ............

up to 5

B

............... 1 ...............

............

80.. ............

A

............... 1

57-l............

80 ..............

6 to 15

55 . . . . . . . . . . . . . .

B

...............

57-2 ............

...............

110.. ...........

A

............... 1 ...............

110.. . . . . . . . . . . .

57-2 ............

16 to 25

75 . . . . . . . . . . . . . .

B

. . . . . . . . . . . . . . . 1 ...............

57-3 ............

125 .............

A

. . . . . . . . . . . . . . . 1 ...............

57-3 ............

125 .............

26 to 35

B

. . . . . . . . . . . . . . . 1 ...............

57-4 ............

150 .............

The rated dry flashover voltage is based on manufacturer's tests where more than one insulator is required.

Use the A value in areas where the atmosphere is dry (desert) or where fog occurs only to a limited degree and there is not more than

moderate industry contamination. Use the B value in areas where medium-to-heavy fog is common occurrence and there is medium

industrial contamination along a salt-water coast line.

4-24

|

|

|

|

||