Custom Search

|

|

|

||

the same port from which it was removed. Carefully follow the manufacturer's

instructions for valve removal and replacement.

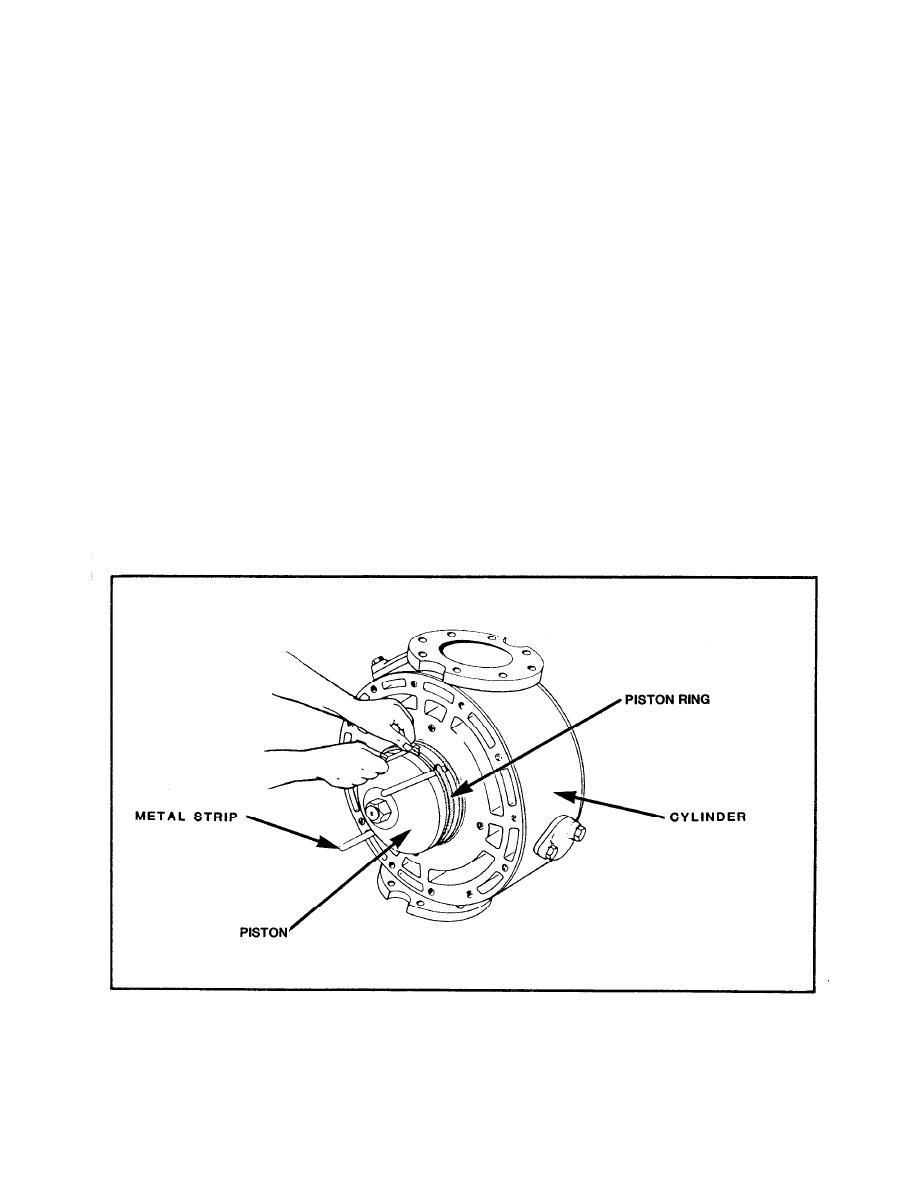

8.5 Piston Rings. When replacing worn piston rings, the new rings must be

tried in the cylinder for fit. If the cylinder wall is badly scored or out of

round, rebore the cylinder, or if cylinder liners are fitted, replace them.

If necessary to file for end clearance, take care to file the ends parallel.

Clean the ring grooves and remove any carbon deposits before installing the

new rings. To install new rings, place several metal strips not more than

0.032-inch thick between the piston and rings (figure 2-2). Slide the new

rings over these strips until they are centered over the grooves and then pull

out the strips. Make sure the ring is free by rotating it in its groove.

Stagger the ring gaps of succeeding rings so they are not in line. Use a ring

clamping device when reinstalling the piston. If this is not available, wire

the rings tightly so they enter the bore easily. Consult the manufacturer's

instructions for carbon ring replacement.

8.5.1 Piston End Clearance. Always check piston end clearance after

replacing pistons or after adjustment or replacement of main, crankpin,

wristpin, or crosshead bearings. Consult the manufacturer's instructions for

proper clearances and method of clearance adjustment. To measure piston end

clearance, insert a length of l/B-inch diameter solder into the cylinder

through a valve port and turn the compressor over by hand so that the piston

moves to the end of its stroke. Remove the compressed solder and measure its

thickness to determine the piston end clearance.

FIGURE 2-2. Installing Piston Rings

2-9

|

|

|

|

||