Custom Search

|

|

|

||

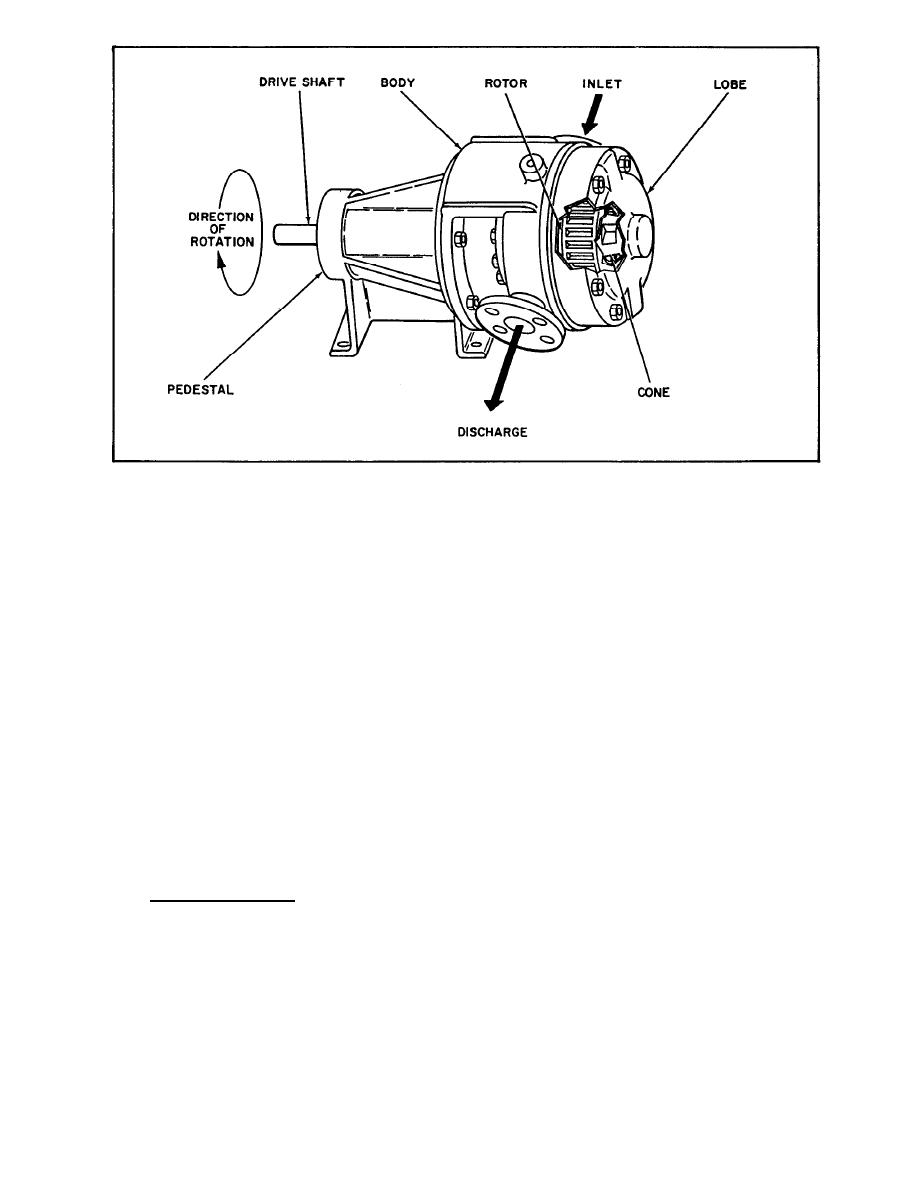

FIGURE 2-11. Functional Elements, Rotary Liquid Piston Compressor

fresh oil. Remove shaft packing. Turn the compressor over by hand once a

week to keep a coating of oil on the bearings.

5 OPERATIONAL PREVENTIVE MAINTENANCE. Operational preventive maintenance

shall include the following tasks.

(a) Never run a liquid piston compressor dry. Operation without

sealing-water results in serious damage to the compressor.

(b) Maintain correct sealing-water flow rate. Insufficient sealing-water

will result in a loss of capacity. Excess sealing-water overloads the

compressor drive. Consult the manufacturer's instructions for correct

sealing-water quantities.

(c) Do not overtighten the packing on units with stuffing boxes. This

results in rapid packing wear and scoring of the shaft.

6 PREVENTIVE MAINTENANCE INSPECTION. The following inspection schedules are

adequate for average installations.

6.1 Daily Inspection. The operator shall inspect the compressor installation

daily for the following conditions:

(a) Unusual noise or vibration

(b) Abnormal discharge pressures

(c) Overheating of motor

2-25

|

|

|

|

||