Custom Search

|

|

|

||

2.2 BASIC CONFIGURATION OF CLOSED-LOOP SYSTEMS

Closed-loop systems use a relatively small pump to move a non-freezing fluid

between the solar collectors and a heat exchanger. The heat exchanger, installed in

a heated space, transfers the heat from the non-freezing fluid to water.

This water is circulated between the heat exchanger and the storage tank by

another relatively small pump. The heat exchanger, pumps and storage tank are all

normally installed in a heated space.

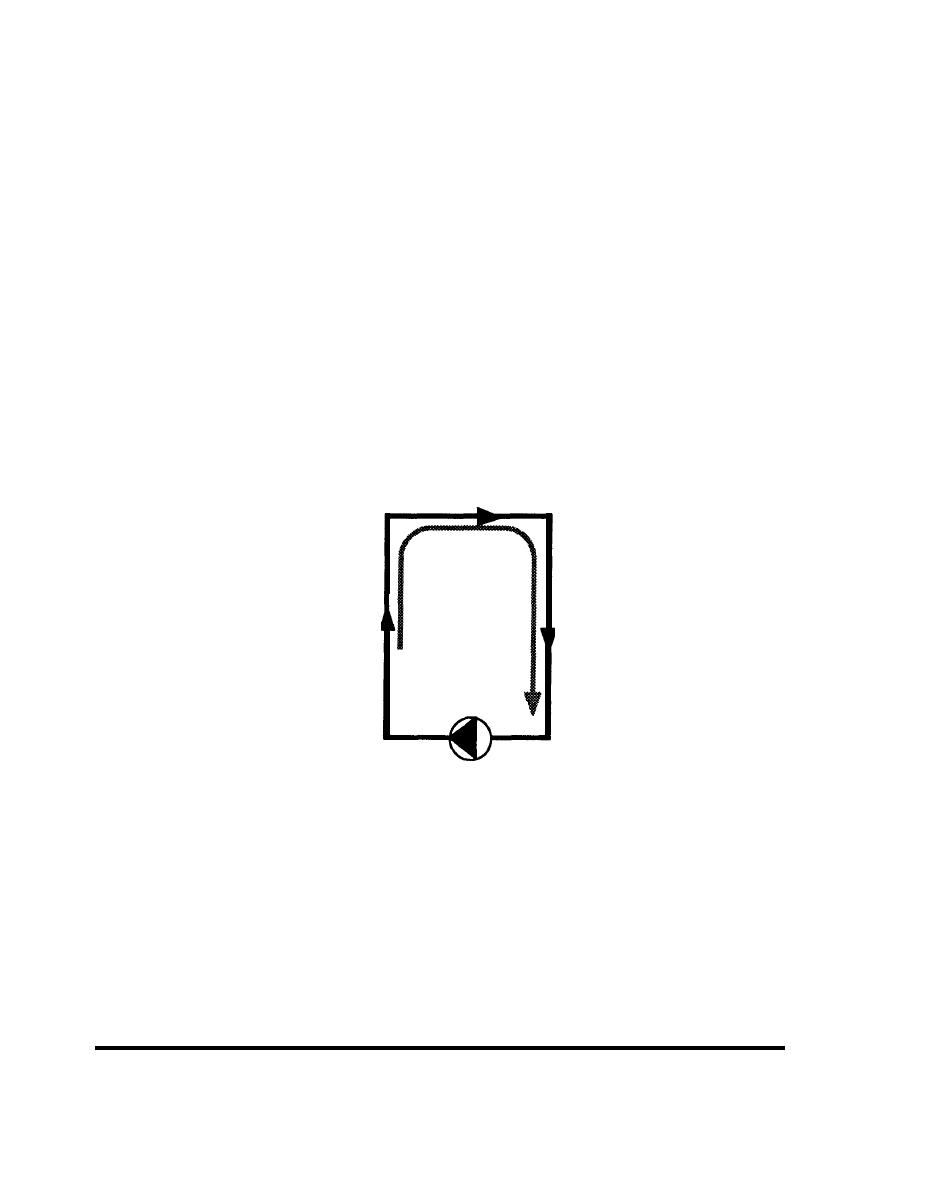

Pumps in a closed-loop system are relatively small because the piping loops they

serve are completely filled. Looking at the collector loop in Figure 2-10, you can see

that, like a siphon, the fluid falling down the return line will pull fluid up the feed line.

Put another way, the energy required to push fluid to the top of the collectors is

offset by gravity pulling it down the other side. The only energy the pump must

supply is that necessary to overcome the resistance due to the friction in the piping.

FIGURE 2-10

Fluid in a Loop.

The fluid falling down

the return line acts to

pull up the fluid in the

feed line. This works

as long as the loop is

completely filled.

CIRCULATING

PUMP

The pump moving the non-freezing solar fluid must be fitted with special seals and

gaskets compatible with the fluid being used. Heat exchanger gaskets and valve

seals must also be chosen carefully. Appendix E shows which materials are

appropriate for various fluids.

The pump circulating water must be of bronze or stainless steel construction, to

avoid corrosion and eventual leakage. The water tubes inside the heat exchanger

must also be made of materials appropriate for water, usually copper or brass.

OPERATION

14

2.2 CLOSED LOOP SYSTEMS

|

|

|

|

||