Custom Search

|

|

|

||

Shafts and Bearings

External motor pumps should be checked for shaft alignment and bearing wear. If

the shaft is out of alignment, bearings will wear quite rapidly. Listening to the pump

is one of the best ways to check these points.

Current Draw

Another excellent way to spot pump problems is by measuring the current draw of

the pump and comparing it to the manufacturer's specifications.

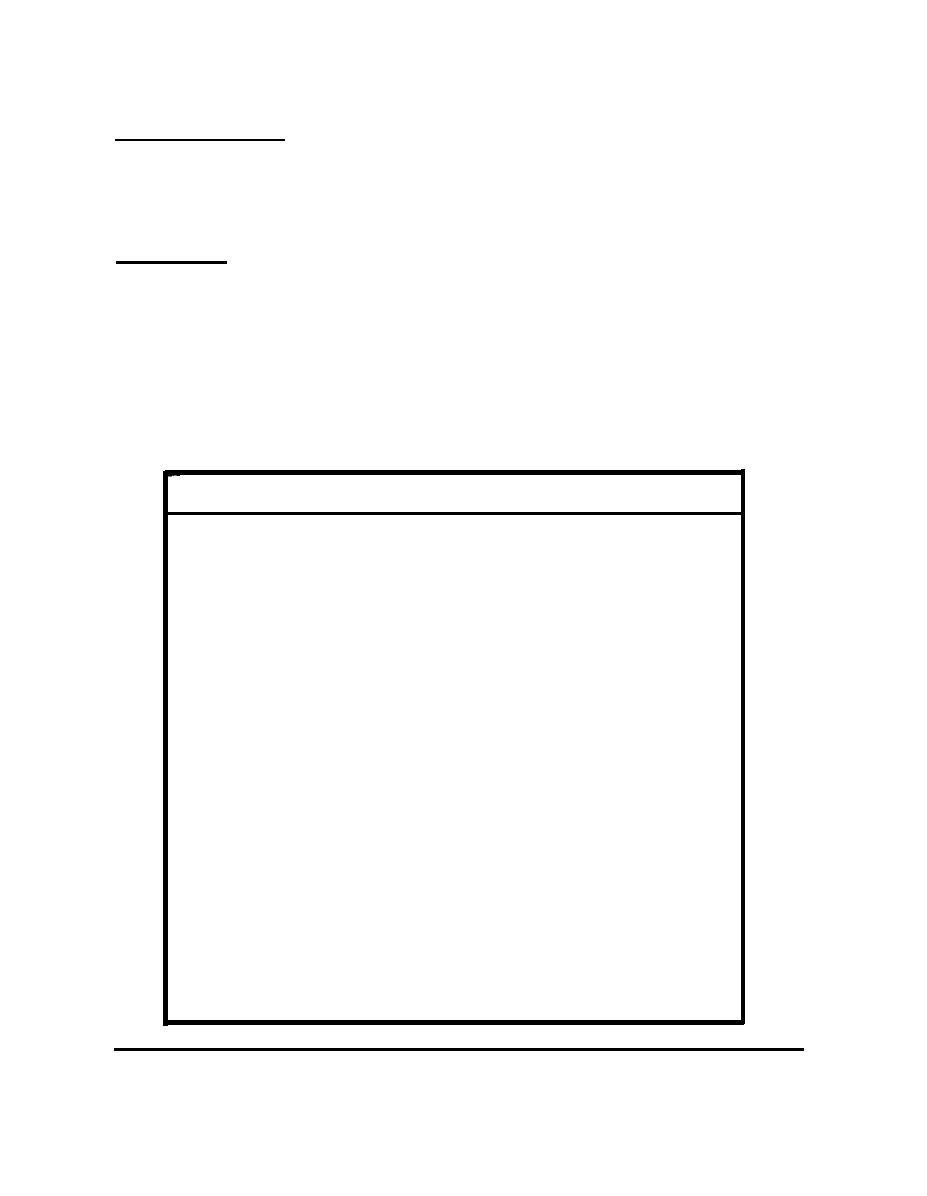

The following table gives a general indication of other things to inspect based on

current readings. "High" and "low" refer to the pump manufacturer's specifications.

TABLE 3-1 : Current Readings and Pump Problems

Inspect for:

If Ammeter Reads:

Power supply problem

Zero

Control problem

Relay or starter problem

Broken motor lead

Thermal overload tripped

Motor problem

Too low

Broken or slipping shaft

(1/4 to 1/2 times

specifications)

Airbound loop

Correct amount

Closed valve, backwards check

valve

Broken or slipping shaft

Direction of motor rotation

Misaligned shaft

Too high

Worn bearings

(1 1/4 to

Foreign matter in volute

1 1/2 times

Impeller against volute wall

specifications)

Motor problem

Locked rotor problem

Much too high

(2 or more times

specifications)

INSPECTION

80

3.1 INSPECTION PROCEDURES

|

|

|

|

||