Custom Search

|

|

|

||

4.3.11 Gauges. Gauges may be checked in two ways. The first is to bring

the gauge to a standard condition. For pressure gauges, remove them from the

system. They should read zero. For thermometers, take them out and put. them in

ice water or boiling water, depending on their temperature range.

The second method is comparison. Replace the suspect gauge with one you know

to be accurate. This is more practical with thermometers than with pressure

gauges.

A typical problem with thermometers is their location. For example, the

thermometer on a storage tank of 120 gallon capacity or less is usually installed in

the outlet piping of the tank. If it is more than a few inches from the tank, the only

time it will accurately report tank temperature is when water from the tank runs by it.

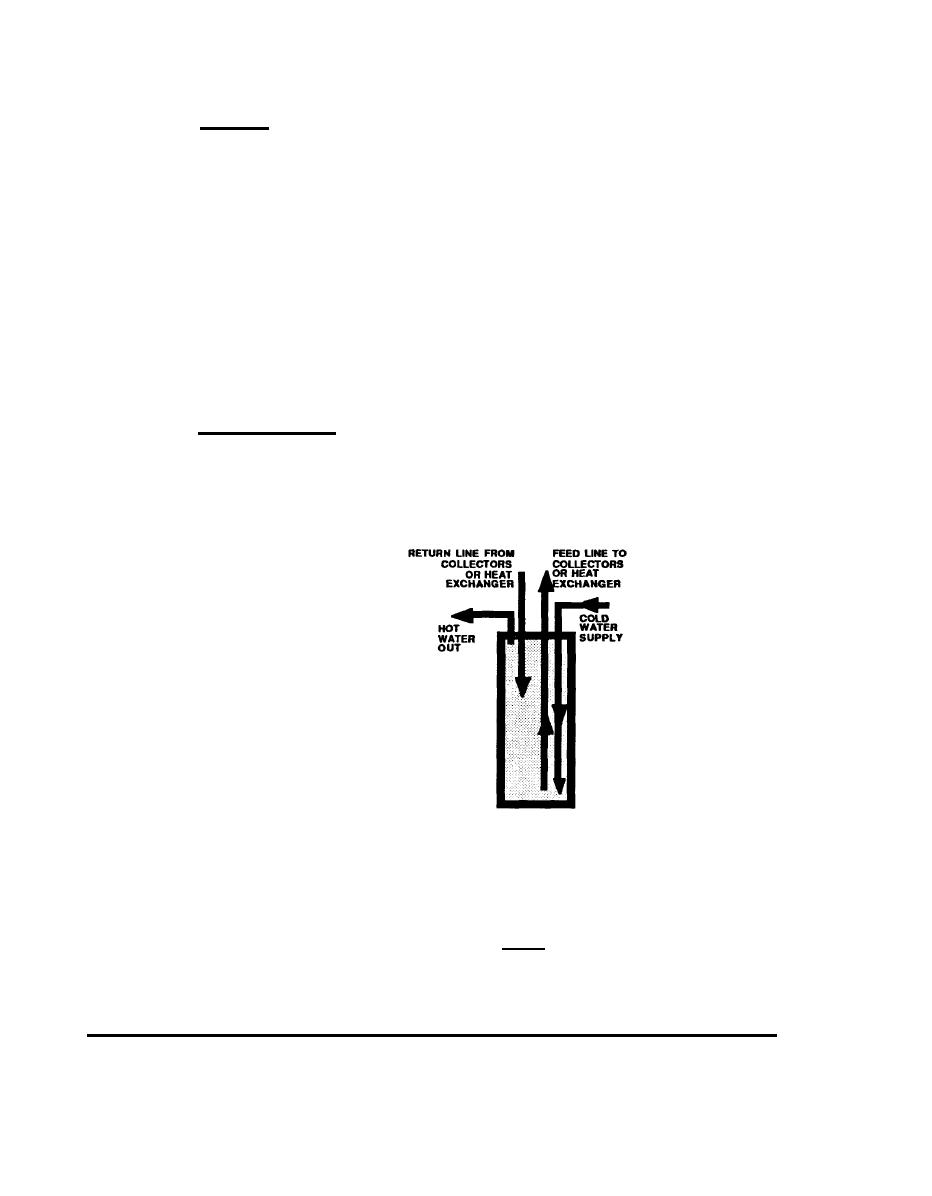

4.3.12 Storage Tanks, Problems with storage tanks may actually be caused

by piping errors. One of the most common is mixing up inlets and outlets. Another

problem is the length of dip tubes. If they are too short or too long, the tank may not

be able to store or deliver its full heat capacity. (Figure 4-9)

FIGURE 4-9

Correct Dip Tube

Lengths in a "Four-Stub

Tank

If the dip tubes are plugged with scale, or collapsed from heat, the system will not

store heat properly. Higher collector loop temperatures is one symptom of this.

Another problem may be an incorrectly positioned auxiliary heating element. For

the system to operate properly, auxiliary elements must be in the upper half of the

tank.

Finally, frequent replacement of anode rods indicates highly corrosive water or an

exposed metal surface.

TROUBLESHOOTING

4.3 TROUBLESHOOTING OPERATIONS

132

|

|

|

|

||