Custom Search

|

|

|

||

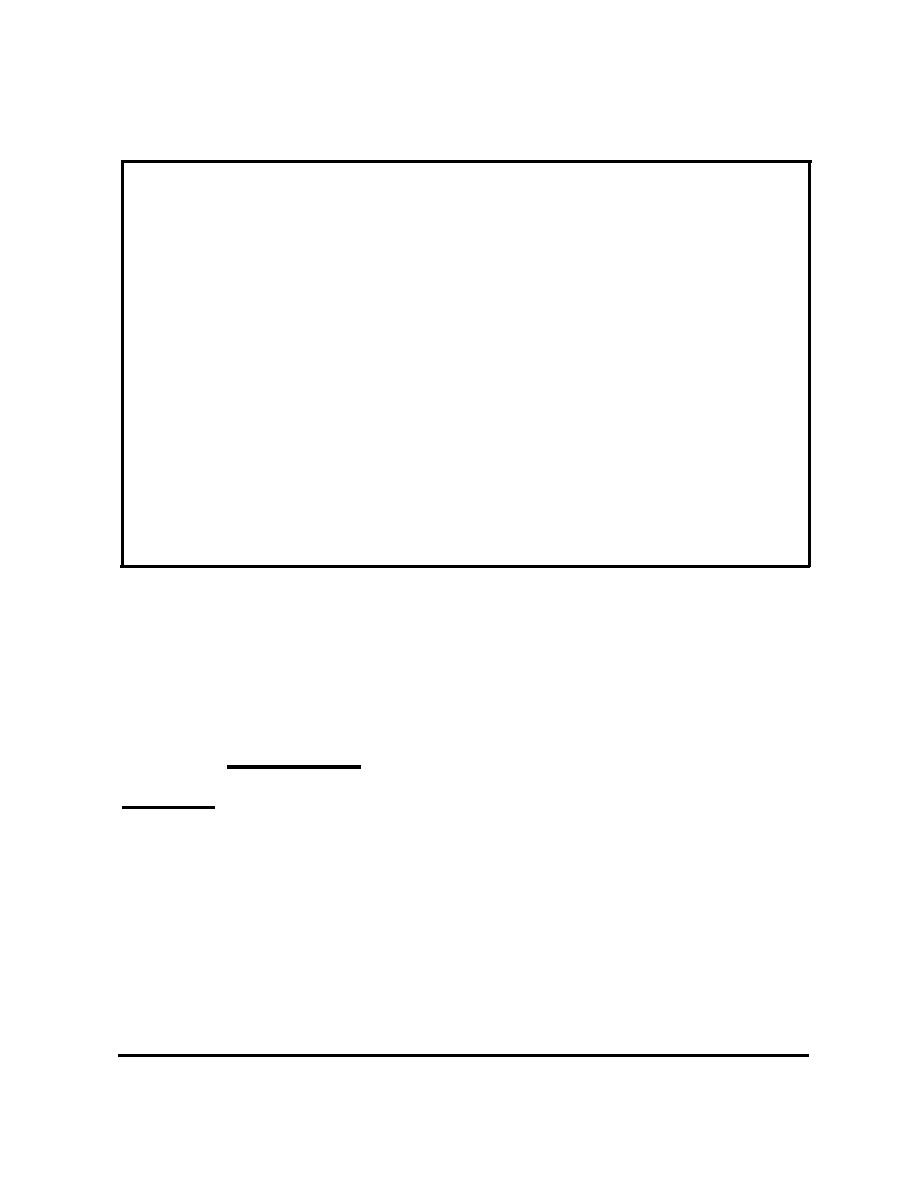

TABLE 5-5: Fluid Pressure for Closed Loops

Extrol Max.

Fluid Pressure, PSI at Fluid Temperatures of:

Tank(s) System

Model # Volume

40F 60F 80F 100F 120F 140F 160F

(Gal.)

1x15

32

33

34

35

36

37

38

4.7

2x15

9.4

32

33

34

35

36

37

38

12.5

35

37

39

40

1 x30

33

34

35

17.2

15+30

33

34

35

36

37

38

40

25.0

2x30

33

34

35

36

37

39

40

44.5

1 x90

33

34

36

37

38

40

42

56.0

30+90

33

34

35

37

38

39

41

2x90

88.0

33

34

36

37

38

40

41

3x90

132.0

33

34

36

37

38

40

41

Note: This chart is based upon sea level pressure. Add one-half pound to

the fill pressure and expansion tank air pressure for every 1000 feet the site

is above sea level.

In all cases, the expansion tank air pressure, measured with no fluid pressure, is 30

PSI at sea level. Add one-half PSI to the listed air pressure and system fill pressure

for every 1000 feet the system is above sea level.

5.2.7 Solar Controls,

Sensor Wires

Damaged or incorrectly routed sensor wires should be replaced with multi-strand,

twisted pair wire of 18 to 22 gauge. Aluminum wire can be used for runs of up to

500 feet. Above that distance, copper should be used.

Although the twisted pair design will reduce interference from electrical "noise" from

other circuits, it must still be at least two feet from other conductors, controls and

loads such as motors. Where it is necessary to cross other wires, do so at a right

angle to minimize induced current (Figure 5-32).

REPAIR

5.2 REPAIR PROCEDURES

187

|

|

|

|

||