Custom Search

|

|

|

||

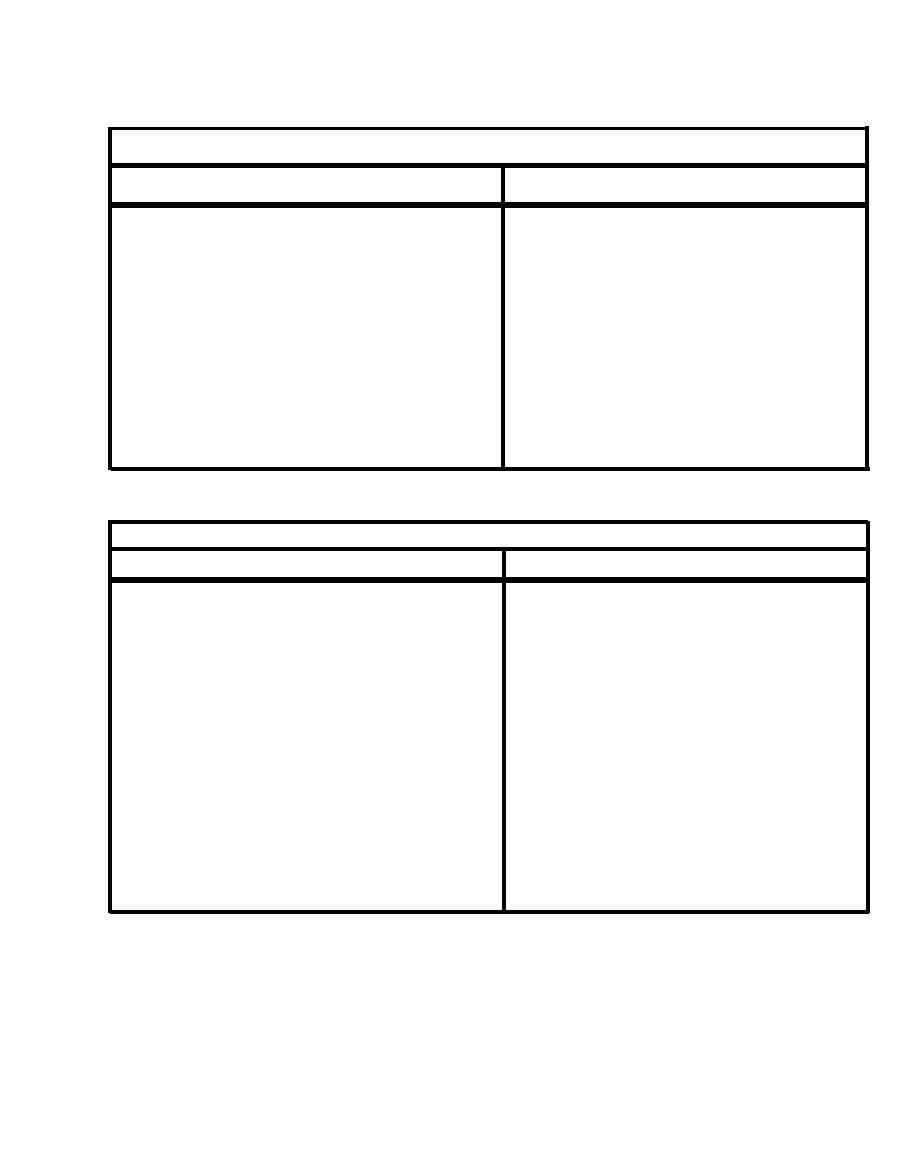

"DO AND DON'T" SUMMARY OF

COMMON DIVING AND RECOMPRESSION CHAMBER SYSTEM DISCREPANCIES

Pressure

Gages

DON'T

DO

o Mount gages against a panel without provisions

o Have gages calibrated at least once a year or if a

for a back-mounted blowout plug to be effective.

Roylyn gage, compared every six months.

o Forget to replace all of the mounting hardware

o Have gages tagged to show when next calibra-

tion or comparison is due.

after gage calibration.

o Remove a gage for calibration without filling out

o Have an isolation valve in line with each gage as

a reentry form and capping off the line to

close to chamber hull or source as possible.

protect it from contamination.

o Have each gage adequately supported.

o Use a gage where the maximum system operat-

ing pressure is more than 75 percent of the gage

scale.

Oxygen System

DON'T

DO

o Use unapproved whips open to contamination.

o Use approved material, fittings, and fabrication

procedures for oxygen system.

o Leave unattached whips open to contamination.

o Keep all oxygen cylinders securely clamped in

place.

o Run oxygen lines so that they contact other

piping, electrical cables, brackets, etc.

o Ensure that BIBS manifolds are adequately sup-

ported.

o Keep deteriorated BIBS masks in manned or

enclosed spaces. Vent overboard to weather if

o Repair or replace BIBS regulators that free flow.

possible.

o Inspect for oxygen leaks from valve packing

stems and seats.

o Do ensure that NO SMOKING signs are

prominently displayed.

D-3

|

|

|

|

||