Custom Search

|

|

|

||

3.9 MAINTENANCE AND OPERATION REQUIREMENTS. Large amounts of water and

bottom sediment are commonly found in waste oils. Excessive amounts of

water in oil can cause flameouts, and excessive solid concentrations can

cause accelerated wear and damage to boiler equipment. Removal of water

and solids from the waste oil prior to burning is essential. Gravity

separation is usually satisfactory. Accelerated separation may be achieved

by heating the oil, blending with other light oil, or using a centrifuge.

Generally, waste oils free of water and sludge can be satisfactorily fired

in boilers either straight or in blends with regular fuel oils. Problems

that may be encountered in burning waste oil are:

Fine lint buildup in barrels and nozzles which are hard to clean.

More frequent cleaning of fuel strainers, up to four times as

often. Use of a duplex strainer is highly recommended.

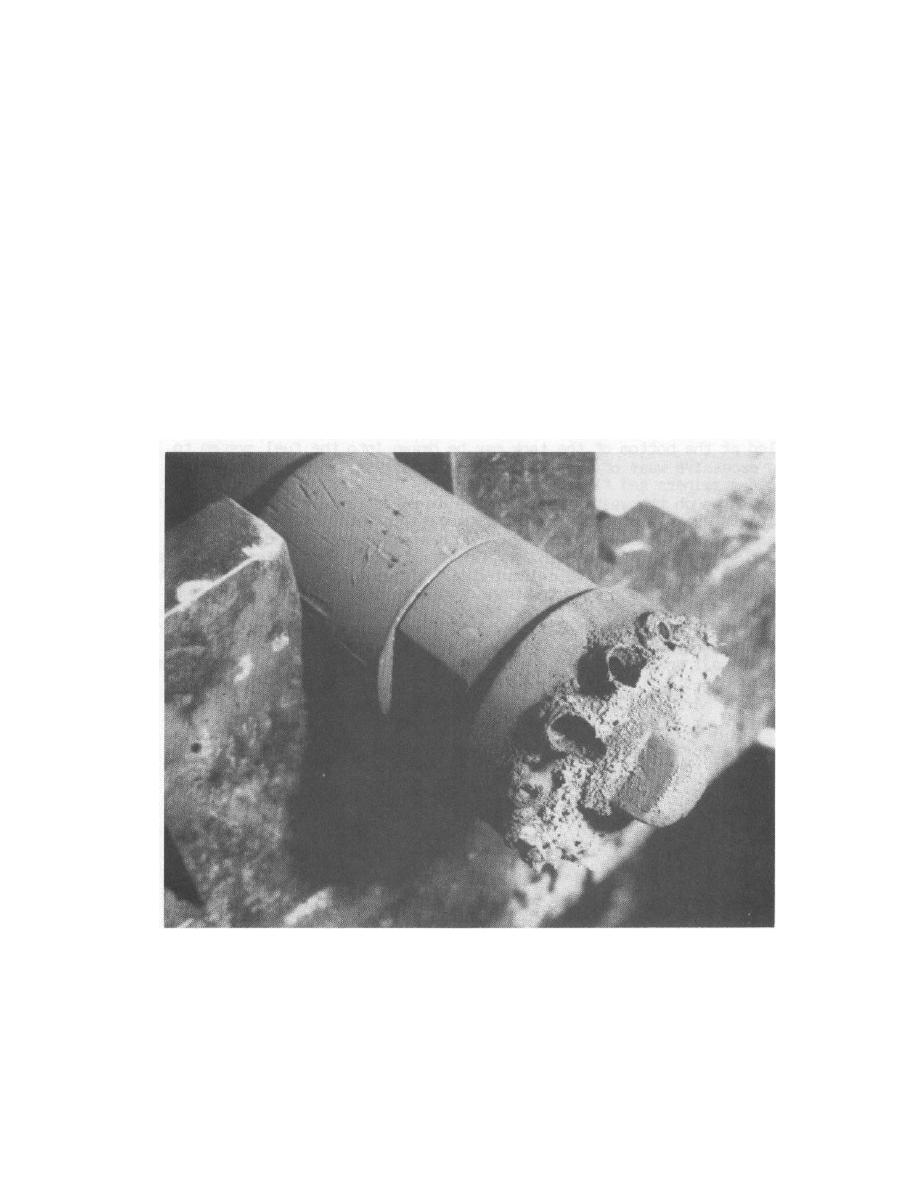

Carbon deposit buildup around the nozzle tip areas due to improper

burner adjustments or worn nozzle orifices (Figure 3-5).

FIGURE 3-5

Nozzle tip with carbon deposit buildup.

31

|

|

|

|

||