Custom Search

|

|

|

||

TM 5-685/NAVFAC MO-912

air at 3 pounds per square inch (psi) to 6 psi) to

sweep the cylinder, further purging the exhaust gas

and providing a fresh clean charge for the next

cycle. The piston reaches and passes through BDC.

The compression stroke then begins again.

b. Four-cycle. The series of events taking place in

a four-cycle engine are: inlet stroke, compression

stroke, expansion or power stroke, and exhaust

stroke. Four strokes (two revolutions of the crank-

shaft) are necessary to complete the cycle.

(1) Inlet stroke. As the piston starts downward

from TDC, the inlet (intake) valve opens and allows

the piston to suck a charge of fresh air into the

cylinder. This air may be supplied at a pressure

higher than atmospheric air by a supercharger.

(2) Compression stroke. As the piston nears

BDC, the air inlet valve closes, sealing the cylinder.

EXHAUST

Energy supplied by the crankshaft from a flywheel,

or power from other cylinders, forces the piston up-

ward toward TDC, rapidly compressing the air and

increasing the temperature and pressure within the

A.

cylinder.

(3) Power stroke. As the piston approaches

TDC, an amount of fuel (modulated by the governor)

is injected (sprayed and atomized) into the cylinder

F U E L INJECTOR

which is ignited by the high temperature, and com-

VALVE OPENS

bustion starts. Combustion, at a controlled rate,

A I R STARTING

further increases the temperature and pressure to

accelerate the piston toward BDC. The expansion of

VALVE OPENS7

the hot gases forces the piston down and turns the

crank against the load. Engine efficiency depends

on the fuel charge being completely burned during

the power stroke.

(4) Exhaust stroke. As the piston passes

through BDC at the end of the power stroke, the

exhaust valve opens. The piston, using stored en-

ergy from the flywheel or from the power stroke of

another cylinder, forces the burned gases from the

cylinder through the exhaust port. As the piston

approaches TDC, the exhaust valve is closed and

the air intake valve opens to begin another cycle.

COMPRESS10

c. Engine timing. Engine timing is critical. Intake

VALVE OPEN

START

OVERLAP-

and exhaust valves have to open a n d close to allow

VALVE CLOSES

the greatest amount of work to be extracted from

combustion. They must also be open long enough to

allow fresh air to flow into and exhaust gas to flow

out of the cylinder. Fuel must be injected at proper

rates during certain periods of time to get smooth

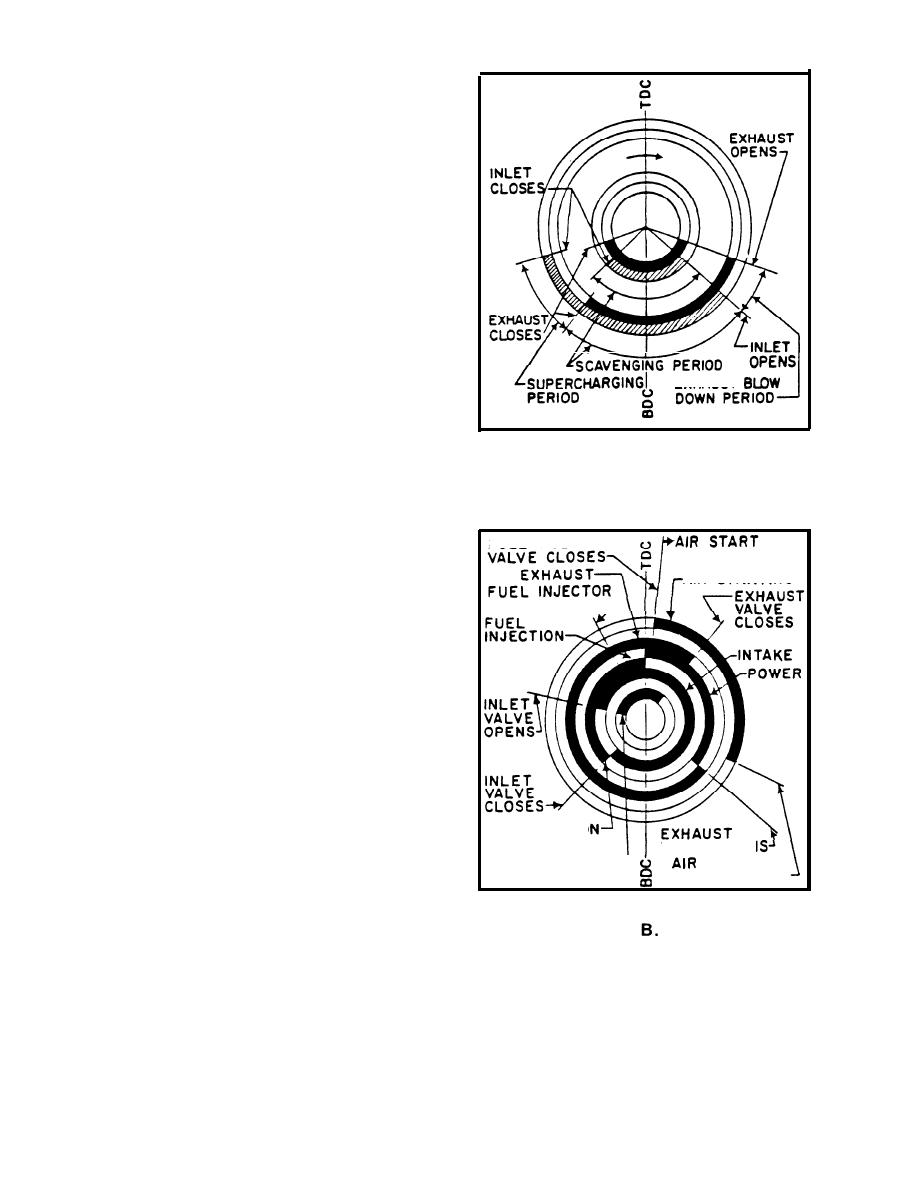

Figure 3-5. Timing diagrams

pressure rise and complete combustion. Timing for

A) FOR A TWO STROKE CYCLE,

two-stroke cycle and four-stroke cycle engines dif-

B) FOR A FOUR STROKE CYCLE.

fers (refer to the timing diagrams in fig 3-5). Dia-

gram A illustrates two forms of the two-stroke cycle

The outer portion covers a port control (uniflow)

engine. The inner portion covers the typical crank-

system. Diagram B illustrates timing for a four-

case scavenging type with uncontrolled fixed ports.

stroke cycle engine.

3-5

|

|

|

|

||