Custom Search

|

|

|

||

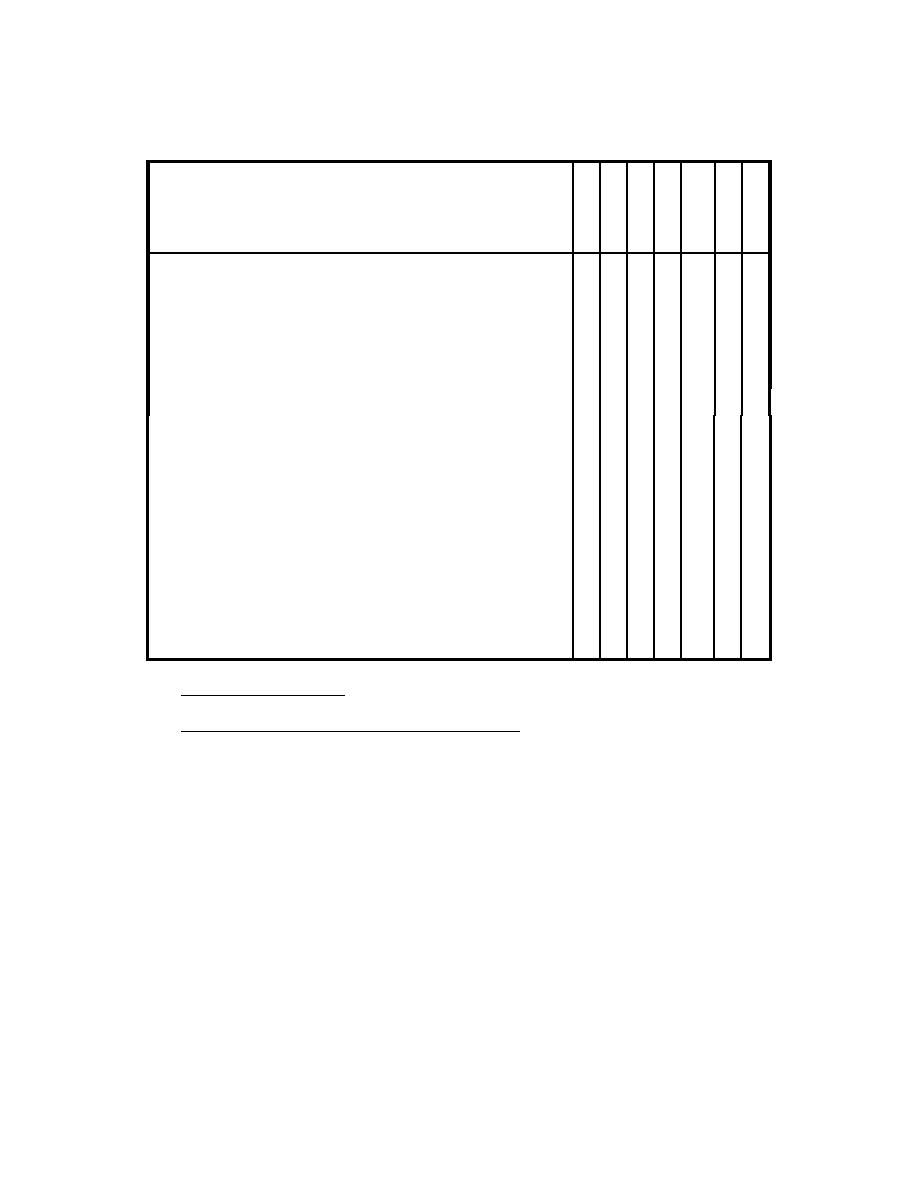

MIL-HDBK-1023/4

Table 7

Preventive Maintenance Inspection Schedule for Wind Cones

D

W

M

B

S

A

U

A

K

T

I

M

N

N

Maintenance Requirement

I

L

H

M

A

N

S

L

Y

L

H

N

L

C

Y

Y

Y

Y

Y

H

1. Check lamp operation.

X

2. Check photocell operation.

X

3. Check for freedom of motion of wind cone frame.

X

4. Check condition of wind cone fabric.

X

5. Check lamp age for scheduled replacement.

X

6. Clean glassware.

X

7. Check paint on segmented circle.

X

8. Clean and grease bearings.

X

9. Read insulation resistance.

X

10. Check mounting bolts.

X

11. Check wiring at hinge.

X

12. Check grounding system resistance.

X

13. Check paint on wind cone structure.

X

14. Remove vegetation and check condition at

X

foundation.

5.4

Airport Lighting Vault

5.4.1

Preventive Maintenance Inspection Procedures. To perform the PMIs contained in

Table 8, proceed as follows:

a) Daily Check. Check the operations of all controls.

b) Bimonthly checks

(1) Cleanliness. Check the general cleanliness of the vault. Sweep out the vault

regularly. Keep it free from dust, dirt, sand, spider webs, insect nests, etc.

(2) Moisture. Check for any collection of moisture. If there is a drain in the floor,

make sure that it is operating properly. Mop up moisture from the floor.

(3) Screens. Check screens on all ventilators. Repair or replace, as necessary, to

keep out wasps and other nest-building insects. Check operation of ventilation fans.

(4) Storage. Check vault for improper use as a storeroom. Avoid storing spare

parts, rags, etc., near the high-voltage equipment. If the vault has an attached room, use this

room for storing spare lamps, fuses, rags, spare parts, etc.

40

|

|

|

|

||