Custom Search

|

|

|

||

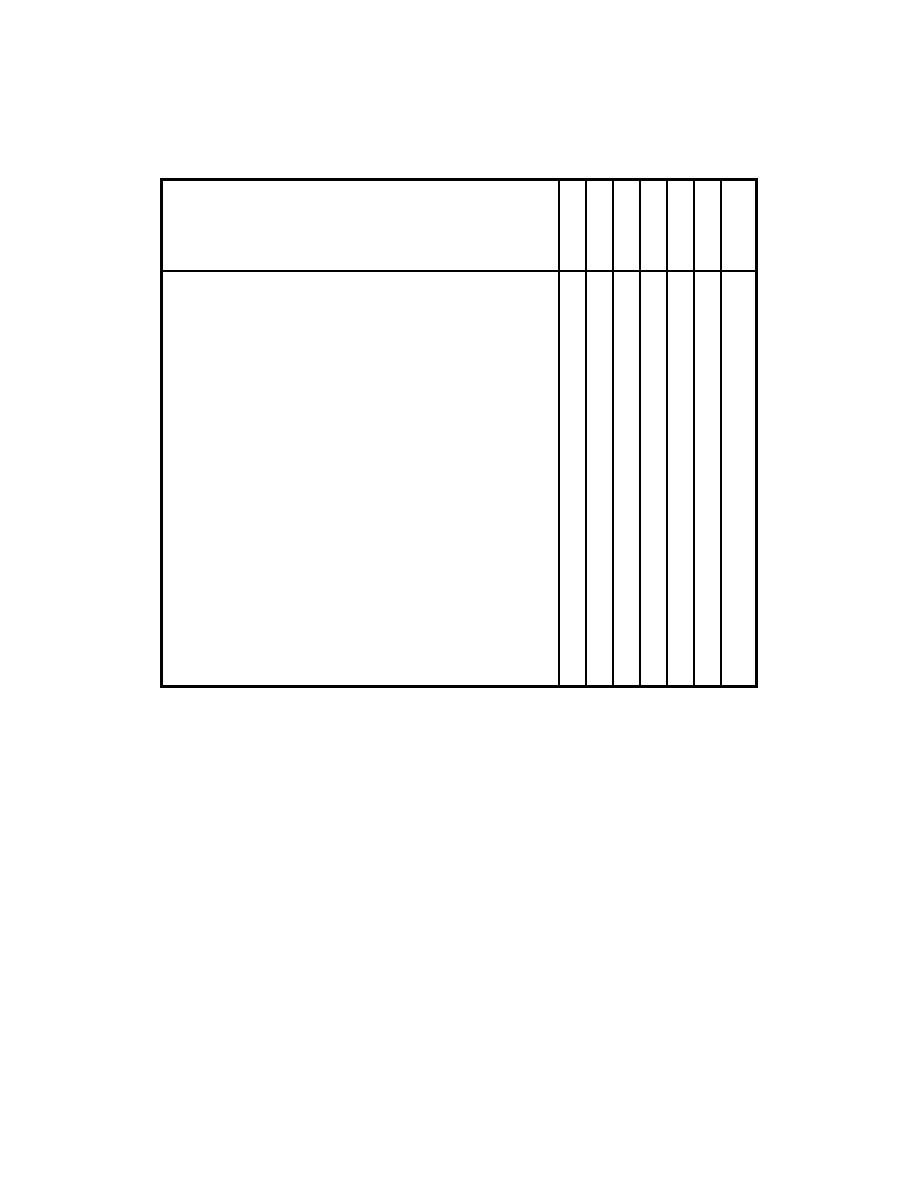

MIL-HDBK-1023/4

Table 11

Preventive Maintenance Inspection Schedule for

Runway and Taxiway Edge Lighting Systems

D

W

M

B

S

A

U

A

K

T

I

M

N

N

Maintenance Requirement

I

L

H

M

A

N

S

L

Y

L

H

N

L

C

Y

Y

Y

Y

Y

H

1.

Inspect for outages; repair as necessary.

X

2.

Check cleanliness of lenses.

X

3.

Check light alignment and orientation.

X

4.

Re-align lights as needed.

X

5.

Clean fixtures and sockets.

X

6.

Inspect and clean frangible coupling weep hole.

X

7.

Check light elevation.

X

8.

Check for moisture in lights.

X

9.

Check for rust, paint deterioration.

X

10.

Inspect fixture for deterioration.

X

11.

Check lamp fitting and clean contacts.

X

12.

Check conditions of all connections.

X

13.

Check cable insulation.

X

14.

Check gaskets.

X

15.

Remove snow from around lights.

X

(2) With the replacement lamp at hand, open up the fixture and remove the old

lamp.

(a) Examine the old lamp to confirm the source of failure.

(b) Compare the identification markings on the old and replacement lamps to

verify that the replacement lamp is the correct type.

(c) Inspect the lamp socket, connections, and wire insulation.

(d) Check the light unit and base for evidence of leakage or condensation and

remove any water present.

(e) Replace fused film disc cutout, if used.

(f) Install new lamps, ensuring that the lamp face is clean and free of oils,

fingerprints, etc. Use a clean, dry, soft cloth and never touch the lamp with unprotected fingers.

47

|

|

|

|

||