Custom Search

|

|

|

||

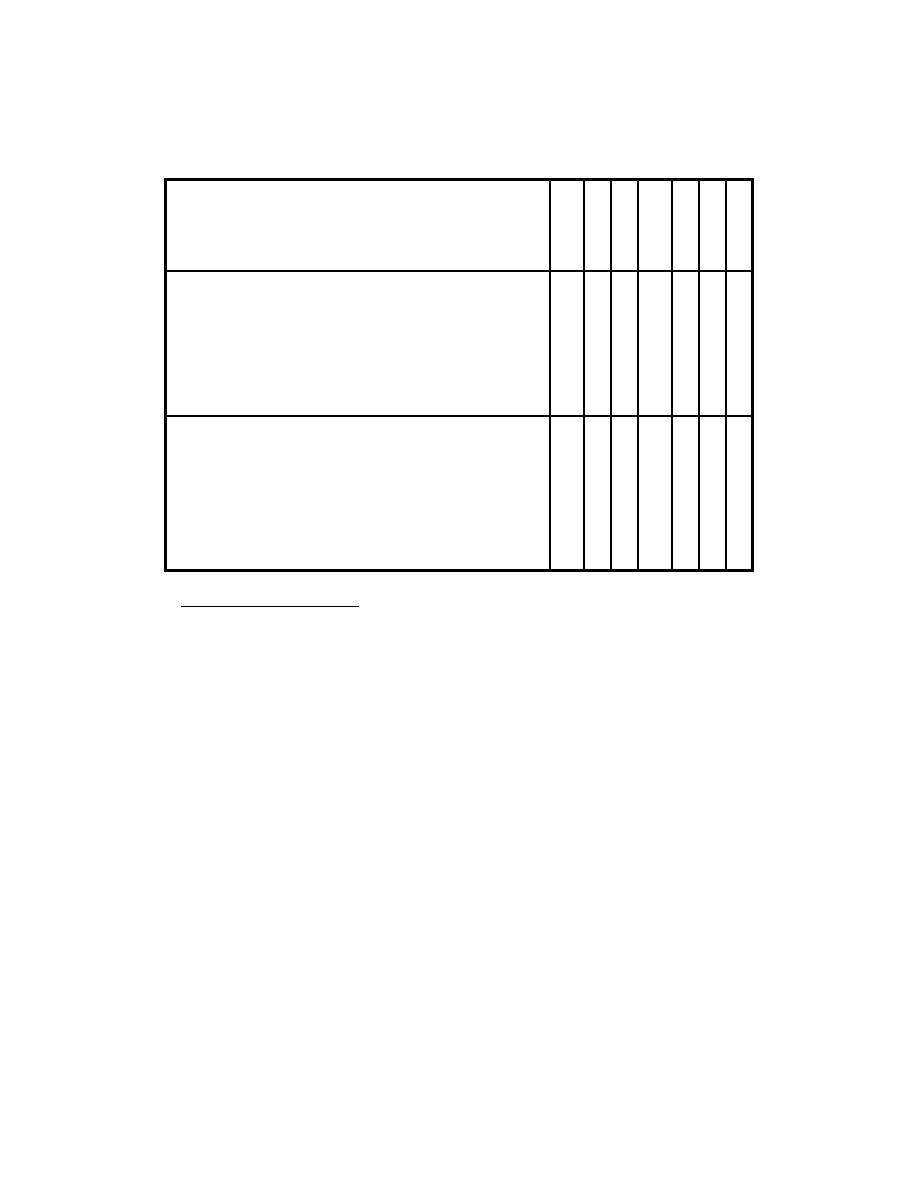

MIL-HDBK-1023/4

Table 13

Preventive Maintenance Inspection Schedule for

Centerline and Touchdown Zone Lighting Systems

D

W

M

B

S

A

U

A

K

T

I

M

N

N

Maintenance requirement

I

L

H

M

A

N

S

L

Y

L

H

N

L

C

Y

Y

Y

Y

Y

H

1.

Check for burned-out or dimly burning lights.

X

2.

Repair or replace defective lights.

X

3.

Clean lights with dirty lenses.

X

4.

Check the intensity of selected lights.

X

5.

Check the torque of mounting bolts.

X

6. Clean and service light; check electrical

X

connections.

7. Check for water in the light base.

X

8. Replace lamps after 80 percent of service life.

X

X

9. Remove snow from around fixtures.

X

10. Check wires in saw kerfs.

X

5.7.2

Maintenance Procedures. Servicing in pavement lighting should be scheduled to cause

the minimum disruption to normal airport operations. For this reason, it is recommended that a

number of spare fixtures be kept for installation in place of defective fixtures. The number of

spare fixtures should be about 10 percent of the total number of in pavement lights in use. By

replacing the defective light with a spare unit, minimum time is spent on the runway; the

defective light may be repaired in the shop. The procedures below give a generalized approach

to repair; for more specific information about a particular light, consult the manufacturer's

instruction book.

a) Light Removal. The light fixture must be removed for relamping or base

inspection. When removing the fixture for base inspection, be careful not to damage the

connections to the isolation transformers. In cold weather, ice or snow may obstruct the bolt

heads and make fixture removal difficult. Some facilities have constructed a wooden box,

slightly larger than the fixture and a few inches tall. The box has an electric heating element

inside, and an open bottom. When it is necessary to remove a frozen fixture, the box is placed

of a truck). When the box heats the fixture enough to melt the ice, removal may be easily

accomplished.

b) Cleaning. Several different techniques are available for cleaning the exterior

glassware of inset lights. Some techniques require special equipment and are suited to large

scale and frequent access with the light installed, while other techniques are more suited to bench

cleaning of a light. The maintenance supervisor should select the method best adapted to the

facility. Remember that not all techniques may be used with all lights; the manufacturer's

recommendations contained in the instruction book are the final authority.

56

|

|

|

|

||