Custom Search

|

|

|

||

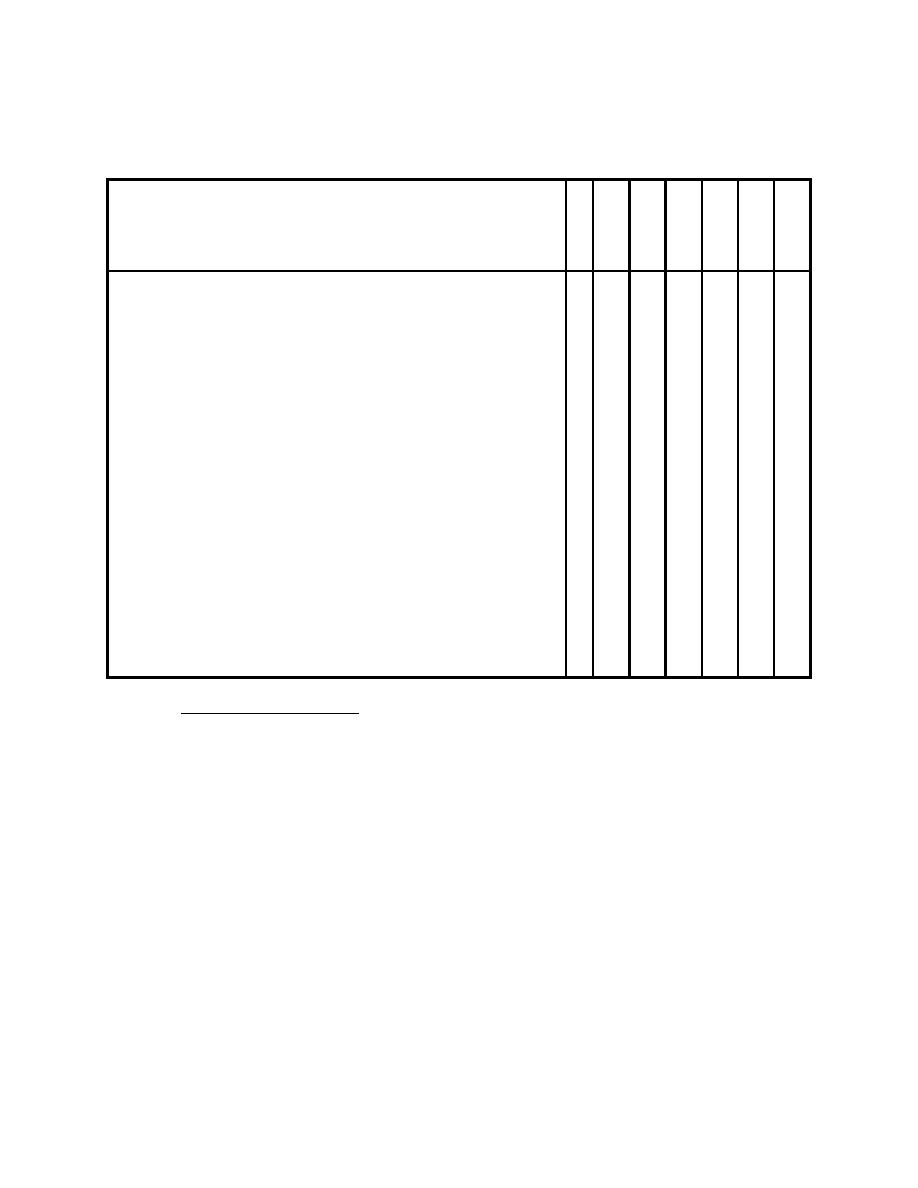

MIL-HDBK-1023/4

Table 14

Preventive Maintenance Inspection Schedule for

Precision Approach Path Indicator (PAPI) System

D

W

M

Q

S

A

U

A

K

T

T

M

N

N

Maintenance Requirement

I

L

H

R

A

N

S

L

Y

L

L

N

L

C

Y

Y

Y

Y

Y

H

1. Check lamps for operation.

X

2. Check operation of controls.

X

3. Check for damage by service vehicles or aircraft.

X

4. Clean lamps and filters.

X

5. Check mechanical parts for damage.

X

6. Check lightning arresters.

X

7. Check for water damage or insect infestation.

X

8. Check for presence of rodents.

X

9. Record output current and input voltage of adapter (if

X

used).

10. Check alignment and aiming of light boxes.

X

11. Check leveling and operation of tilt switch.

X

12. Check integrity of obstacle-free approach plane.

X

13. Check insulation resistance of underground cables.

X

14. Check resistance of grounding system.

X

5.8.2

Maintenance Procedures

a) Adjustment of the Vertical Aiming. This is normally done with a clinometer or

small (machinist's) level. Handle these precision instruments carefully. Make sure the aiming

device is the one supplied with the PAPI light units.

(1) Check the manufacturer manual (supplied with the units) for the procedures

used to check each PAPI unit for proper aiming angle. Follow the procedures recommended for

using the manufacturer's leveling device.

(2) Stand in front of the PAPI units (approximately 50 feet away) and check that

the light changes color simultaneously along the whole width of each unit. If not, horizontal

leveling was not done properly, the red filters are out of position, or the box is warped.

(3) Check the tilt switch on all units (where provided) by placing the small level on

the marked top surface of the tilt switch and adjusting the tilt switch if necessary. If the tilt

switch shuts off the power when it is level, the tilt switch should be replaced. The main switch

may have to be toggled off and on to reset tilt switch circuit. For tolerances, refer to the

manufacturer's installation manual.

61

|

|

|

|

||