Custom Search

|

|

|

||

MIL-HDBK-419A

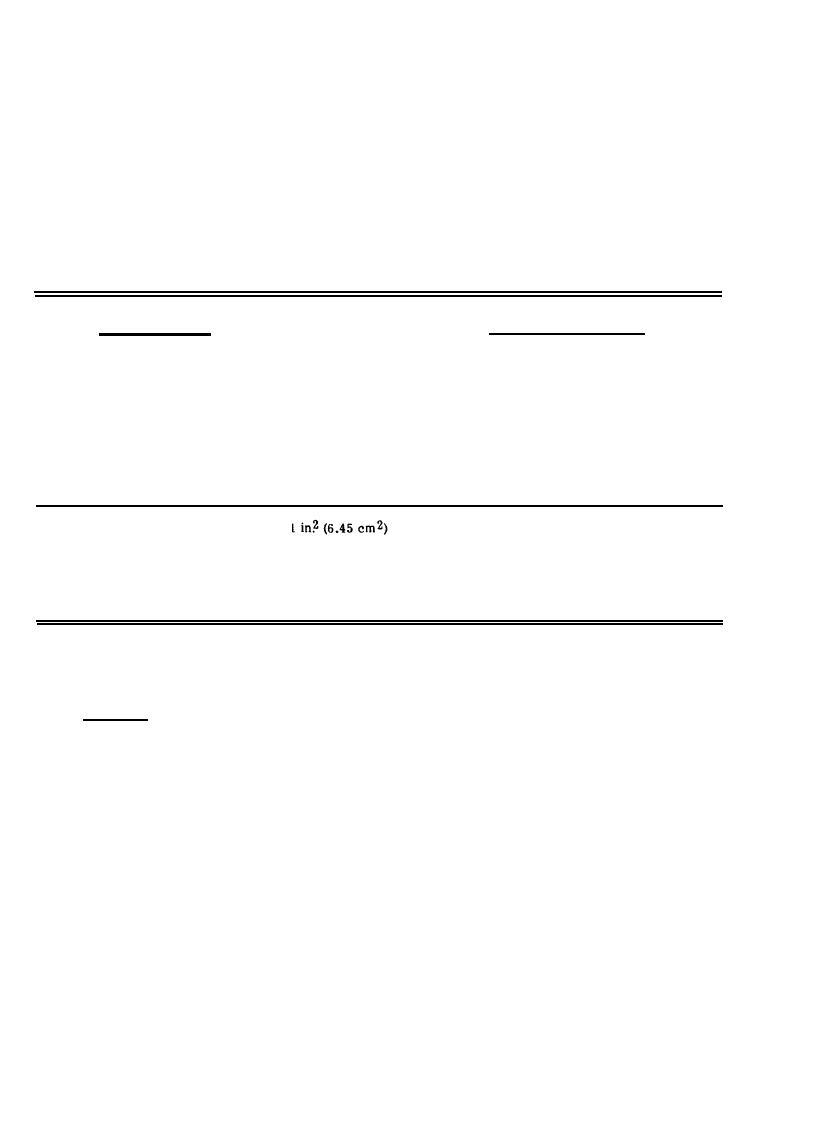

Table 7-1

DC Resistance of Direct Bonds Between Selected Metals

Resistance (Micro-ohms)

Bond Composition

Brass-Brass

6

Aluminum-Aluminum

25

Brass-Aluminum

50

150

Brass-Steel

Aluminum-Steel

300

Steel-Steel

1500

Notes: Apparent Bond Area:

Fastener Torque: 100 in -lb

Source: Adapted from Reference (7-5)

7.4.1.4 Bond Area.

Smaller bond areas with the same loadings would produce higher contact pressure which would decrease the

resistance. However, as shown in Figure 7-4, an increase in pressure over 1500 psi for steel and 1200 psi for

aluminum produces relatively slight changes in bond resistance. Further, the improvement in resistance due to

increased pressure is offset by the smaller overall bond area. In a similar fashion, a larger bond area (with no

change in fastener size) under the same torque results in a lowered pressure at the bond surfaces. The reduced

pressure would be counterbalanced to some extent by the increased bond area, but the net effect can be

expected to be an increase in bond resistance. Thus, when larger bond areas are used, larger bolts at

correspondingly higher torques should be used for fastening. (See Para 7.4.2.4)

7-8

|

|

|

|

||