Custom Search

|

|

|

||

MIL-HDBK-419A

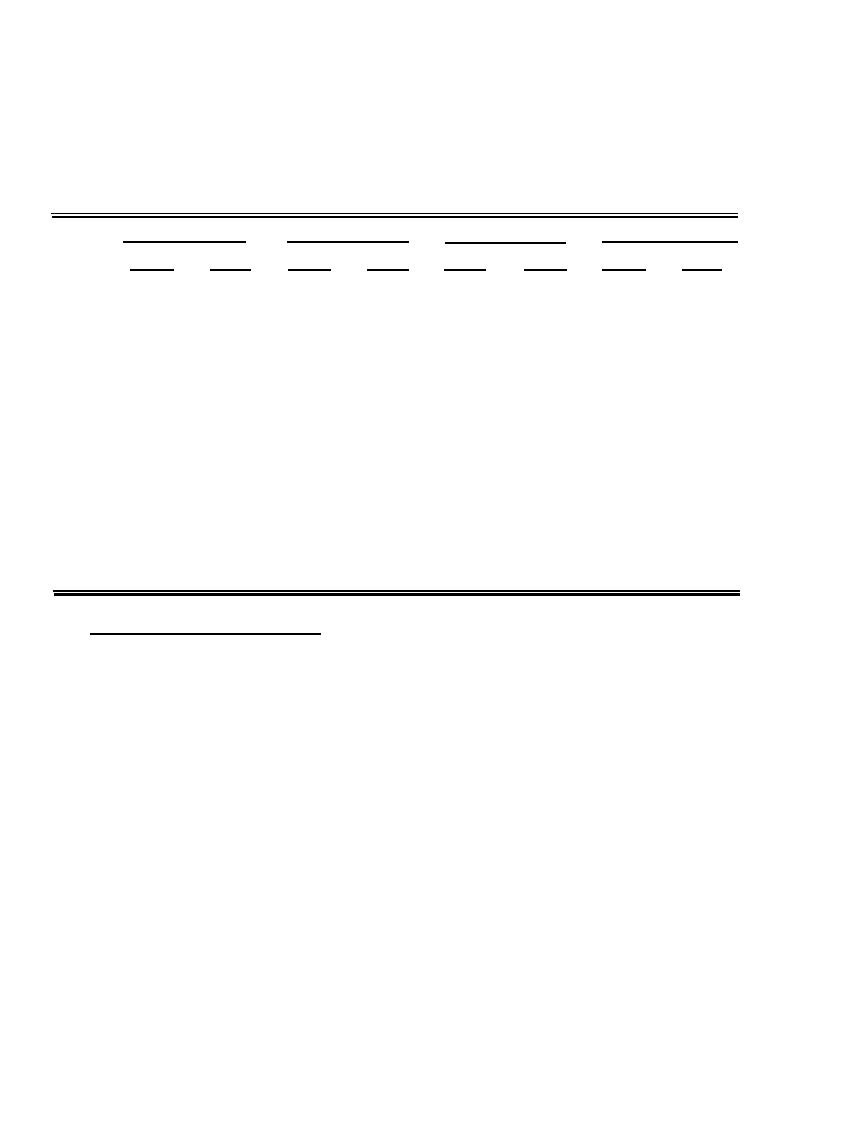

Table 8-11 provides representative calculations of the shielding effectiveness of thin-film cover for different

thicknesses and frequencies. One-quarter wavelength in copper is approximately 0.13 mils at 1 GHz, and it can

be seen that shield effectiveness changes significantly above this thickness.

Table 8-11

Calculated Values of Copper Thin-Film Shielding Effectiveness in dB Against Plane-Wave Energy (8-7)

0.0041 M i l s

0.86 Mils

Thickness

0.086 M i l s

0.049 M i l s

1 GHz

1 MHz

1 GHz

1 GHz

1 MHz

1 MHz

1 GHz

1 MHz

Absorption

92

0.014

0.44

9.2

2.9

5.2

0.29

Loss, A

0.16

Single

109

79

109

79

79

109

79

Loss, R

109

Multiple

Correction

-47

-17

-26

-6

-21

0.6

-3.5

Term, C

Shield

Effectiveness,

62

62

83

78

90

108

171

SE

88

8.4.3 Screens and Perforated Metal Shields.

There are many applications in which the shield cannot be made of a solid material. Screens and perforated

materials must be employed if an enclosure must be transparent (e.g., a meter face) or ventilated. The

shielding effectiveness of solid metal shields has been treated from the viewpoint of classical transmission line

theory in the preceding sections. To obtain an expression for shielding effectiveness which is applicable to

screens and perforated metal sheets, it is necessary to account for the following:

a.

The attenuation effects of the individual shield apertures

acting as

many

stacked

waveguides-below-cutoff (see Section 8.5.3.1).

b.

Reflection losses, considering the geometry of the openings.

c.

Area of the opening when the test antenna is far from the shield in comparison to the distance

between holes in the shield.

d.

Skin depth effects.

e.

Coupling between closely spaced openings.

8-33

|

|

|

|

||