Custom Search

|

|

|

||

MIL-HDBK-419A

d.

Certain protective metal platings such as cadmium, tin, or silver need not in general be removed.

Similarly, low-impedance corrosion-resistant finishes suitable for aluminum alloys, such as alodine, iridite,

oakite, turco and bonderrite, may be retained. Most other coatings, such as anodizing, are nonconductive and

should be removed. See Figure 8-22 for shielding effectiveness degradation data on selected surface finishes.

e.

Mating surfaces should be bonded immediately after protective coatings are removed to avoid

oxidation. Refinishing after bonding is acceptable from the standpoint of shielding effectiveness.

f.

When two dissimilar metals must be bonded, metals that are close to one another in the

electrochemical series should be selected in order to reduce corrosion.

Soldering may be used to fill the resulting seam, but should not be employed to provide bond

g.

strength.

h . The most desirable bond is achieved through a continuous butt or lap weld. Spot welding is less

desirable because of the tendency for buckling, and the possibility of corrosion occurring between welds.

Riveting or pinning is even less desirable because of the greater susceptibility of bond degradation with wear.

i.

An overlap seam, accompanied by soldering or spot welding, provides a relatively effective bond.

Other types of crimped seams may be employed so long as the crimping pressure is uniformly maintained.

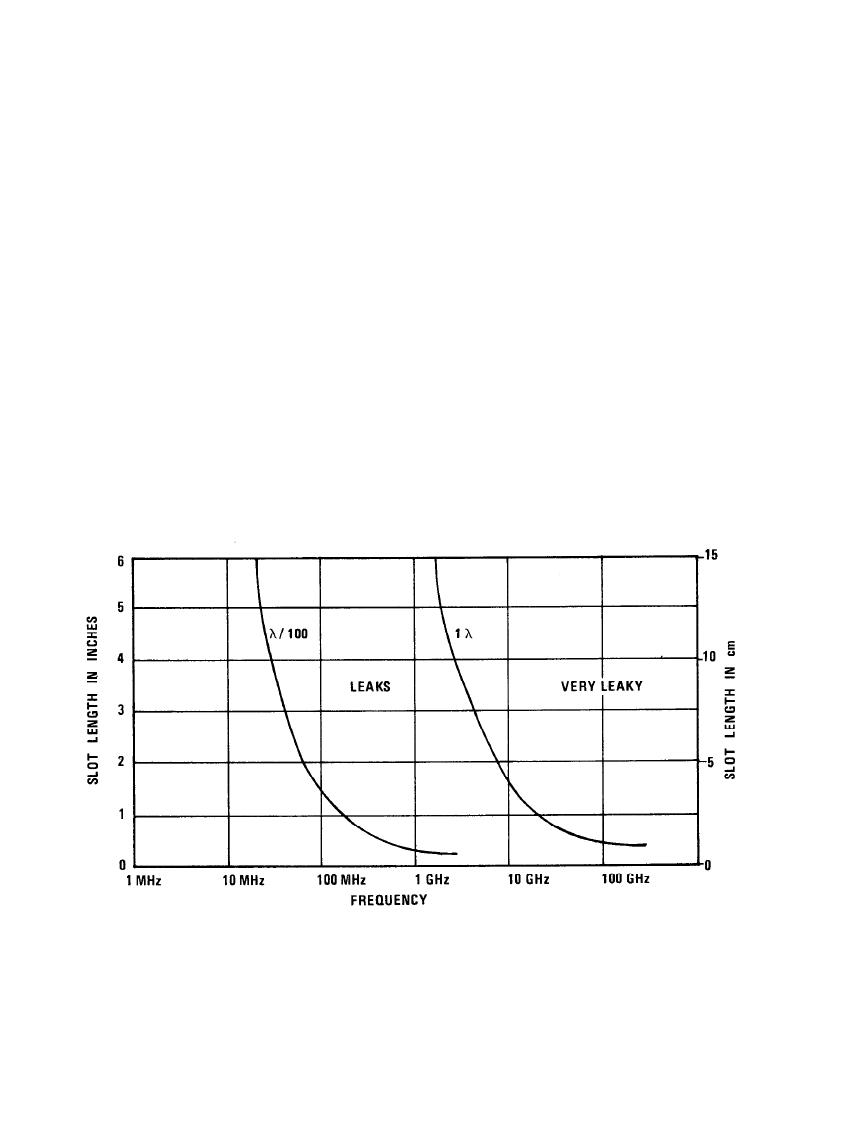

Figure 8-21. Slot Radiation (Leakage) (8-9)

8-43

|

|

|

|

||