Custom Search

|

|

|

||

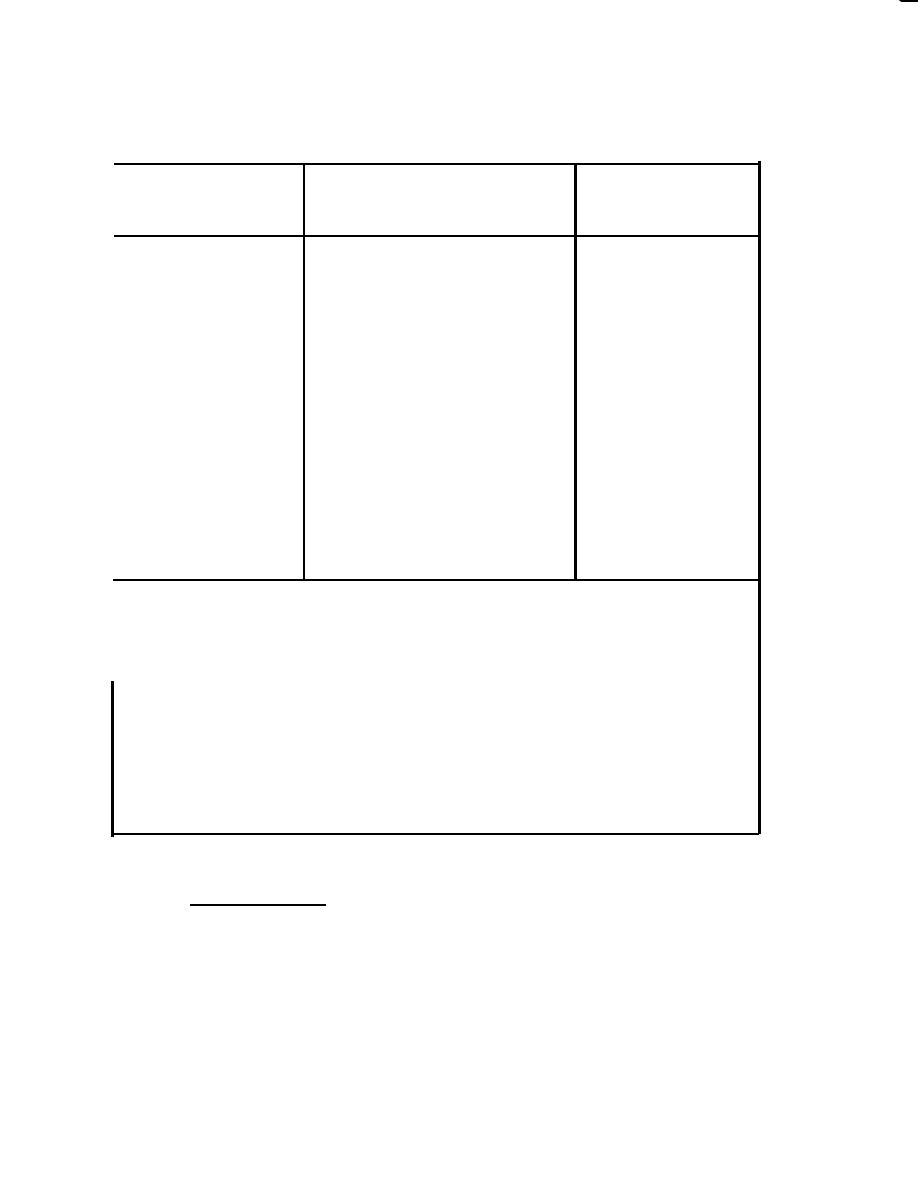

TABLE 4-1

Range of Capture Velocities

Condition of

Capture Velocity

Examples

of Contaminant

(fpm)

50-100

Released with

Evaporation from tanks;

degreasing, etc.

practically

no velocity

into quiet air.

100-200

Released at

Spray booths; intermittent

low velocity

container filling; low

speed conveyor transfers;

into moderately

welding; plating; pickling

still air.

200-500

Spray painting in shallow

Active generation

booths; barrel filling;

into zone of

conveyor loading; crushers

rapid air motion

500-2000

Grinding; abrasive

Released at high

blasting, tumbling

initial velocity

into zone of very

rapid air motion.

The

In each category above, a range of capture velocity is shown.

proper choice of values depends on several factors:

Upper End of Range

Lower End of Range

1. Disturbing room air currents.

1. Room air currents minimal or

favorable to capture.

2. Contaminants of high

2. Contaminants of low toxicity

toxicity.

or of nuisance value only.

3. High production, heavy use.

3. Intermittent, low production.

4. Small hood-local control

4. Large hood-large air mass

only.

in motion.

4.3.2 Dust Collectors. Dust collectors are usually designed for much

heavier loads from industrial processes where the air or gas to be cleaned

originates in local systems or process stack gas effluents. Loading will

vary from less than 0.1 to 20 grains or more per cubic foot.

4-3

|

|

|

|

||