Custom Search

|

|

|

||

TM 5-683/NAVFAC MO-116/AFJMAN 32-1083

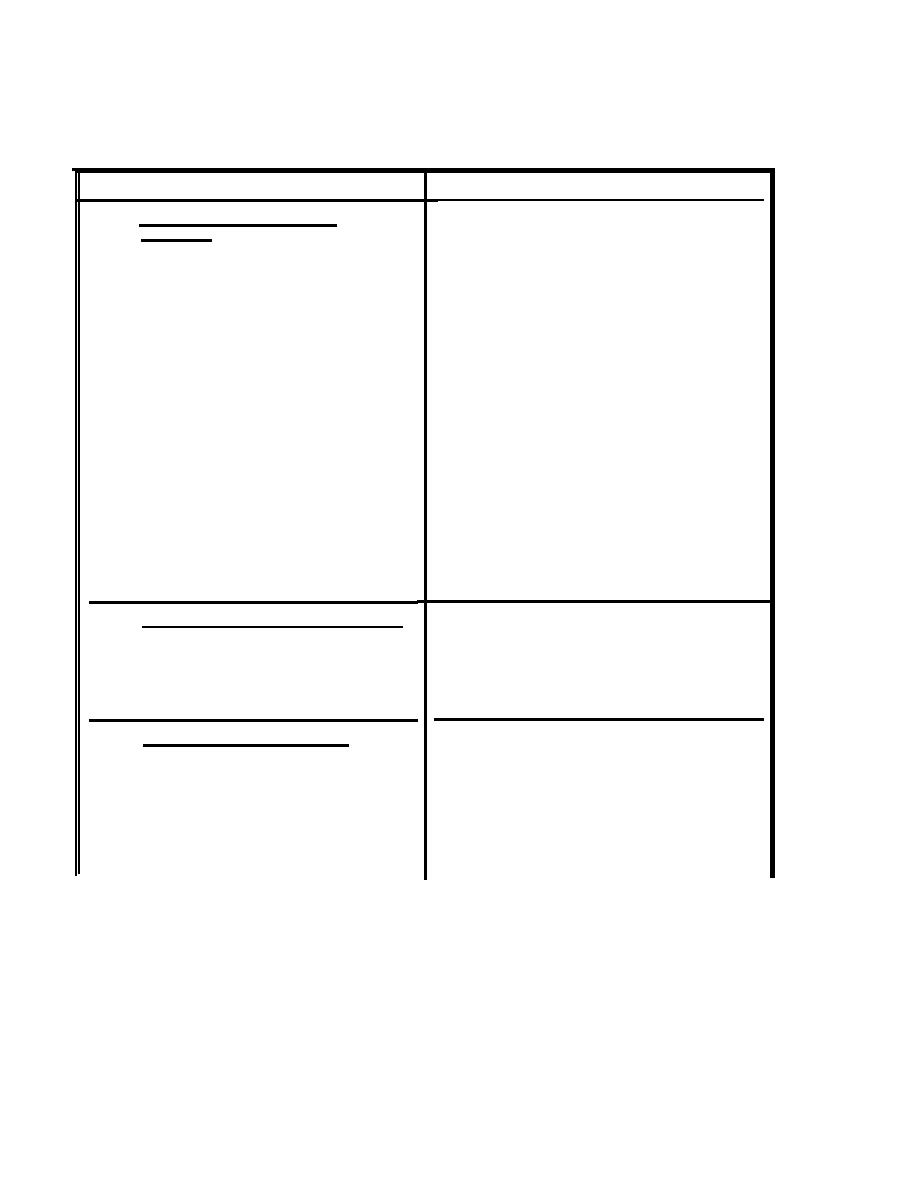

Table 2-2. Trouble-shooting procedures for switchgear equipment - continued.

CAUSE

REMEDY

4.

R e l a y s Failing to Trip

Breakers

Adjust setting to correspond with

circuit conditions.

Improper setting.

C l e a n contacts with burnishing tool.

Do not use emery or sandpaper.

D i r t y , corroded or tarnished

contacts.

Readjust so that contacts close with

proper amount of wipe.

Contacts improperly adjusted.

Check with instruments to a s c e r t a i n

that voltage is applied and that

c u r r e n t is passing through relay.

O p e n circuits or short

circuits in relay connections.

T a r g e t and holding coils should

c o r r e s p o n d with tripping duty of

breaker to assure proper tripping.

Improper application of target

If timing device is of bellows or

and holding coil.

oil-film type, clean and adjust. If

of induction-disk type, check for

m e c h a n i c a l interference.

F a u l t y or improperly adjusted

t i m i n g devices.

5.

N o i s e s Due to Vibrating P a r t s

Tighten.

Loose bolts or nuts permitting

excessive vibration.

T i g h t e n any loose nuts or core

L o o s e laminations in cores of

clamps.

transformers. reactors, etc.

6.

C o n n e c t i o n s Overheating

I n c r e a s e the number or size of

I n c r e a s e of current due to

conductors.

R e m o v e excess current

a d d i t i o n a l load that is beyond

from circuit.

n o r m a l current rating of bars

or cables.

T i g h t e n all bolts and nuts. Too

B o l t s and nuts in the

much pressure must be avoided.

connection joints not tight.

2-18

|

|

|

|

||