Custom Search

|

|

|

||

TM 5-683/NAVFAC MO-116/AFJMAN 32-1083

rotor bars. The symptoms of such conditions are

slowing down under load and reduced starting

torque. Repairs to cast aluminum rotors with open

bars are not feasible and such rotors have to be

replaced. Copper bar rotors can usually be repaired

by rebrazing the joints.

(2) Bearings. The bearings are the most critical

mechanical part of a motor. To assure maximum

life, bearings should be subjected to careful inspec-

tion at scheduled intervals. The frequency of inspec-

tion is best determined by a study of the particular

motor operating conditions. Bearings are subject to

metal fatigue and will eventually wear out even

though they are correctly applied, installed and

maintained. Fatigue failures are characterized by

flaking of the race surfaces along the ball or roller.

Fatigue is a gradual process, which is dependent

upon load and speed and usually is made apparent

in its early stages by an increase in the operating

temperature, vibration or noise level of the bearing.

Bearing failures not attributed to fatigue failure are

usually classified as premature. The majority of

these premature failures are caused by the fol-

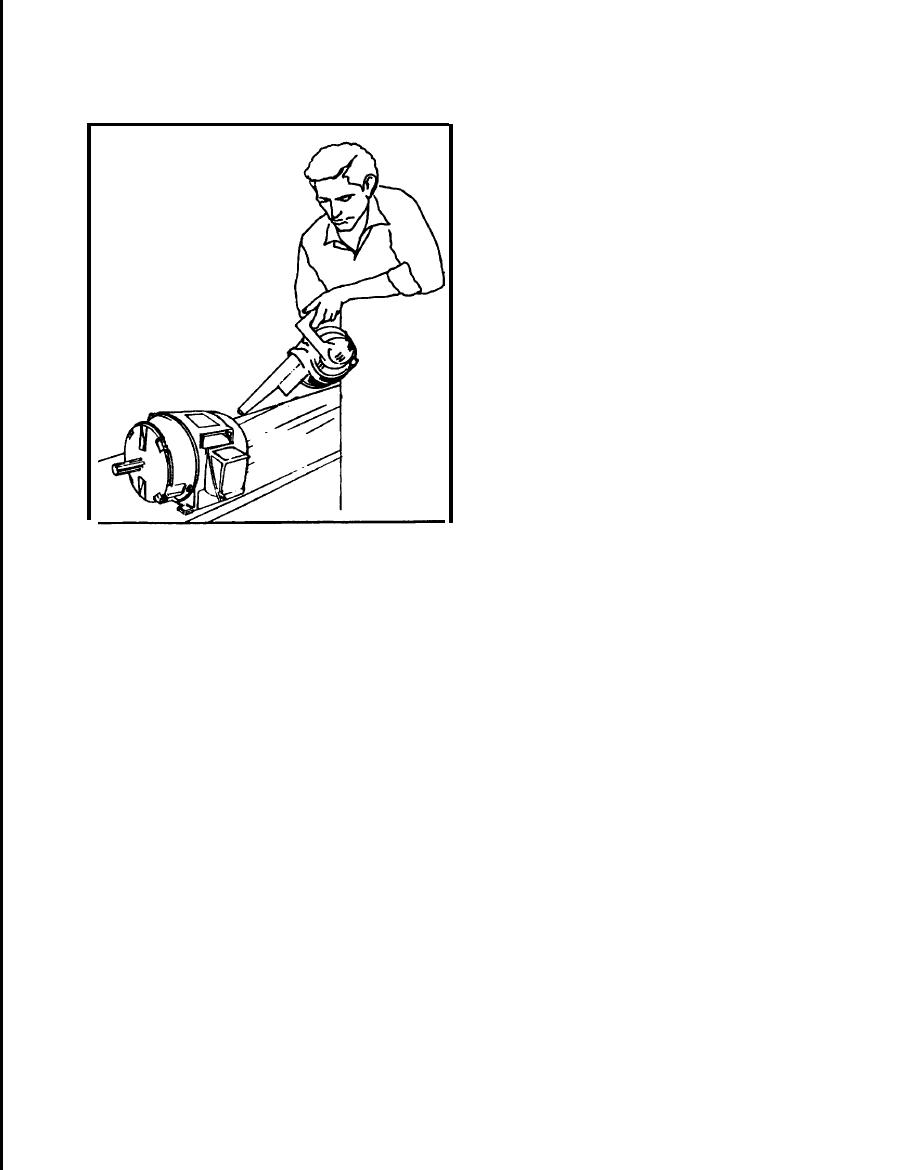

Figure 4-5 Cleaning and drying motors in place.

lowing: incorrect bearing type; misalignment of the

motor or load; misalignment or improperly installed

winding. However, there is some hazard since the

bearing; rusting during storage; preloading or im-

heat generated in the inner parts is not readily

proper end-play adjustment; excessive thrust or ra-

dissipated. This method should be followed only un-

dial force; axial indentations; improper lubrication

der competent supervision. For synchronous mo-

and entrance of contaminants into bearing. Follow

tors, the "short circuit method" is sometimes used.

manufacturer's instructions and use lubricants as

This method is achieved by shorting the armature

specified. When using greases, store in clean con-

windings, driving the rotor and applying sufficient

tainers, handle with clean paddles or use a grease

field excitation to give somewhat less than full load

gun and keep containers covered. Do not overfill

armature current. Once the drying process has been

bearing housings. Overfilling contributes to heat

completed, insulation testing of the motor winding

is recommended to determine whether the insula-

build-up, damaged seals, leaks and collecting of

tion has been properly reconditioned. If a motor

dirt. Overheating is particularly true of bearings

running at high speeds. Machines that are normally

must continue to operate in a damp environment,

idle for long periods should be exercised on a sched-

then special enclosures are necessary to limit the

uled basis. Exercising will keep the oil circulated,

effects of a moist atmosphere.

reduce condensation within the housing and lessen

(c) Inspecting motor windings. Check wind-

ing tightness in the slots or on the pole pieces. One

the chances of flat spots developing on the bearing

condition which hastens winding failure is move-

races, balls or rollers. Inspect seals and vents regu-

ment of the coils due to vibration during operation.

larly. Periodic maintenance services of bearings in-

Check insulation surfaces for cracks, crazing, flak-

volves keeping a bearing dry, covered, clean and

ing, powdering, or other evidence of need to renew

lubricated as well as checking operating tempera-

insulation. Usually under these conditions, when

ture. A clean bearing is particularly critical because

the winding is still tight in the slots, a coat or two of

dirt means damage. It is therefore important to

air-drying varnish may restore the insulation to a

remember the following when cleaning bearings (fig

safe value. Check the winding mechanical supports

4-6):

for insulation quality and tightness, the binding

(a) Work with clean tools in clean surround-

ring on the stator windings, and the glass or wire-

ings. Do not use wooden mallets, dirty, chipped or

wound bands on rotating windings. E x a m i n e

brittle tools, or work on rough or dirty bench tops.

squirrel-cage rotors for excessive heating or discol-

(b) Remove all dirt from the housing before

ored rotor bars which may indicate open circuits or

exposing the bearings and take care to prevent loose

high resistance points between the end rings and

dirt from getting into the housing.

4-11

|

|

|

|

||