Custom Search

|

|

|

||

TM 5-683/NAVFAC MO-116/AFJMAN 32-1083

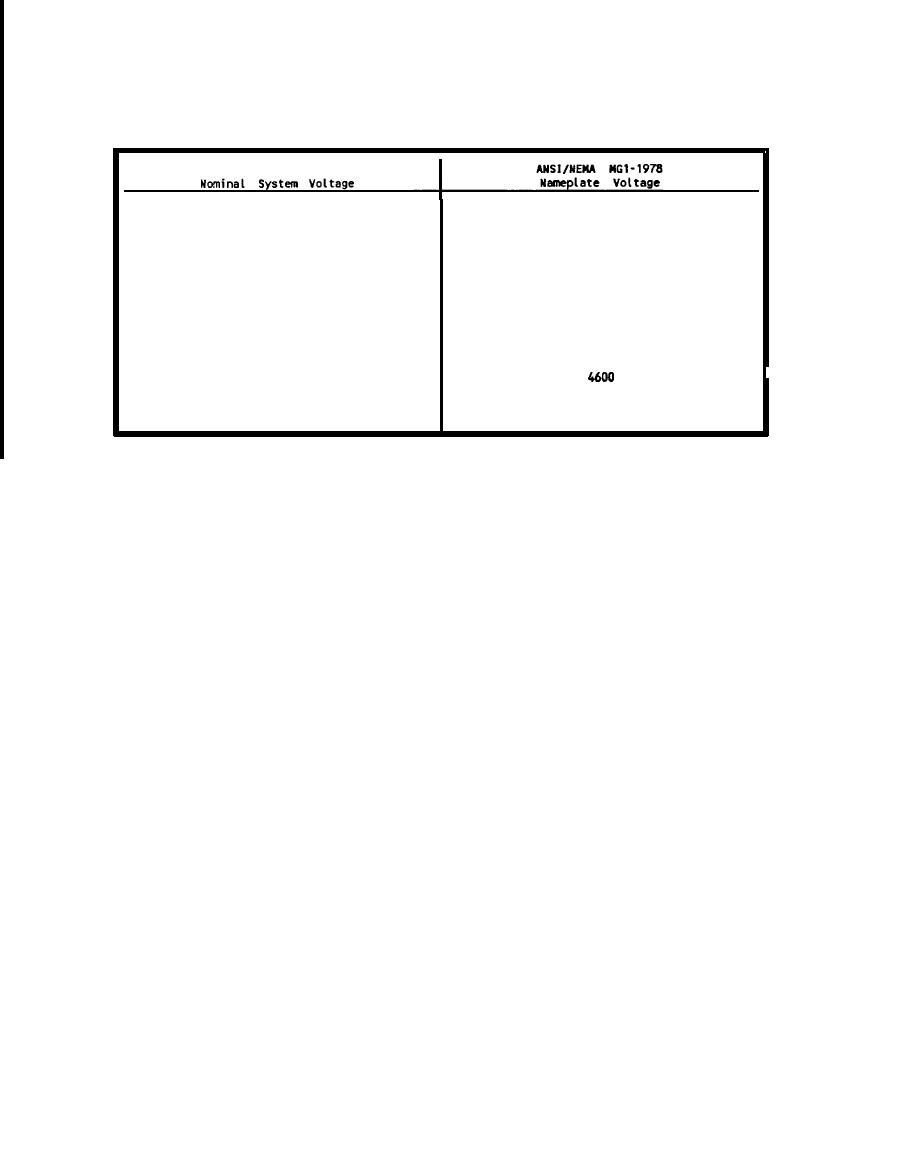

Table 4-2. Nameplate voltage ratings of standard induction motors.

Single-phase rotors

120

115

240

230

Three-phase motors

208

200

240

230

480

460

600

575

2400

2300

4160

4000

4800

6900

6600

13,800

13,200

(a) From ANSI/IEEE Std. 141-1984

or stationary field windings. Before testing the mo-

"special order" rewinding repairs or replacements

tor insulation, de-energize the circuit. Then discon-

for general purpose work. There are some cases

nect any potentially low insulation sources, such as

where substitution cannot be used. An exact voltage

lightning arresters, capacitors and other voltage

replacement should be ordered if:

sources. Lead-in cables or busses and line-side cir-

(1) The motor is known to be delivering 100

cuit breakers or starters can be tested as a part of

percent or more, continuously.

the circuit provided a satisfactory reading is ob-

(2) Motor has a duty rating other than "con-

tained. Motor test connections for AC and DC mo-

tinuous" or "24 hours".

tors are shown in figure 4-21. If the insulation

(3) Motor is marked, "special purpose", or "se-

resistance is below the established minimum, the

vere duty" on nameplate.

circuit components should be tested separately to

(4) A non-standard voltage is shown and no

isolate the source of low impedance. All data should

horsepower rating is given.

be recorded and compared to previous periodic read-

4-5. Motor insulation testing.

ings. Any persistent downward trend is an indica-

tion of insulation trouble even though the values

The electrical test most often conducted to deter-

may be higher than the recommended minimum

mine the quality of low voltage motor armature and

winding insulation is the insulation resistance test.

acceptance values which are:

AC and DC motor (250V or less) 500,000 OHMS

There are other tests available to determine the

AC and DC motor (1OOOV or less) 1 MEGOHM

quality of motor insulation, but they are not recom-

mended for low voltage motor testing because they

4-6. Motor trouble-shooting.

are generally too complex or destructive. An insula-

Tables 4-3, 4-4 and 4-5 provide detailed data on

tion resistance test should be conducted on rotating

machinery immediately following their shutdown

troubleshooting motor breakdowns. Motor troubles

along with their probable cause(s) and recom-

when the windings are still hot and dry. A megohm-

mended maintenance or corrective actions are also

meter (para 134) is the recommended test equip-

given.

ment. It should be applied to armature and rotating

4-24

|

|

|

|

||