Custom Search

|

|

|

||

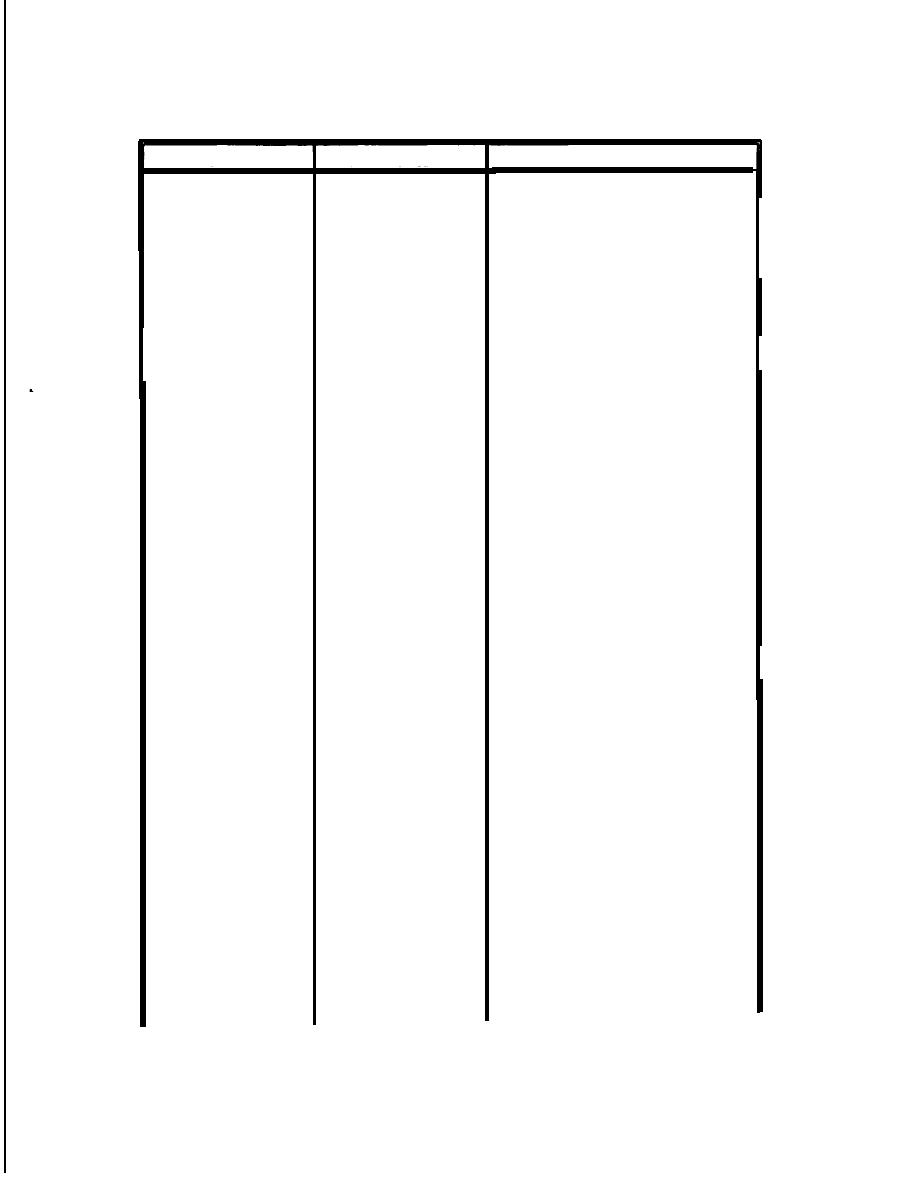

TM 5-683/NAVFAC MO-116/AFJMAN 32-1083

Table 4-3. AC indution motor trouble-shooting-continued.

Maintenance

Probable

Cause

Trouble

Replace bearings.

Bearings damaged

Ball bearings

hot

(cont'd. )

(corrosion, etc. )

Check

Check coupling joint.

Coupling loose.

Tighten coupling.

alignment.

Wound rotor motor

troubles

Use larger cable to c o n t r o l .

Wires to

control

too

Motor runs at low

small.

speed with external

resistance cut out.

Bring control nearer m o t o r .

Control too far from

motor.

Test to find open circuit and

Open circuit in rotor

repair.

circuit (including

cable to control).

Check for looseness, overload, or

Brushes sparking.

dirt.

Clean rings and insulation

Dirt between brush

assembly.

and ring.

U s e right size b r u s h , c l e a n

Brushes stuck in

holders.

holders.

Clean brush tension and correct.

Incorrect brush

tension.

Sand and polish.

Rough collector

rings.

Turn in lathe or use portable tool

Eccentric rings.

to true up rings without

disassembling motor.

connectons or

Correct

open

Open rotor circuit.

Excessive vibration

control.

and noise.

Reduce load.

(If brushes have

Current density of

been replaced, make sure they are

brushes too high

of the same grade as originally

(overload).

furnished.

Consult

Low current density.

Ring threading

manufacturer for different brush

recommendation.

I n s p e c t for open or poor

Motor

will

not

start

Faulty Connection.

connect ion.

Test,

locate and r e p a i r .

Open circuit one

phase.

Open and repair.

one

Short circuit

phase.

too

Reduce the impedance of the

Voltage falls

external circuit.

low.

4-29

|

|

|

|

||