Custom Search

|

|

|

||

TM 5-683/NAVFAC MO-116/AFJMAN 32-1083

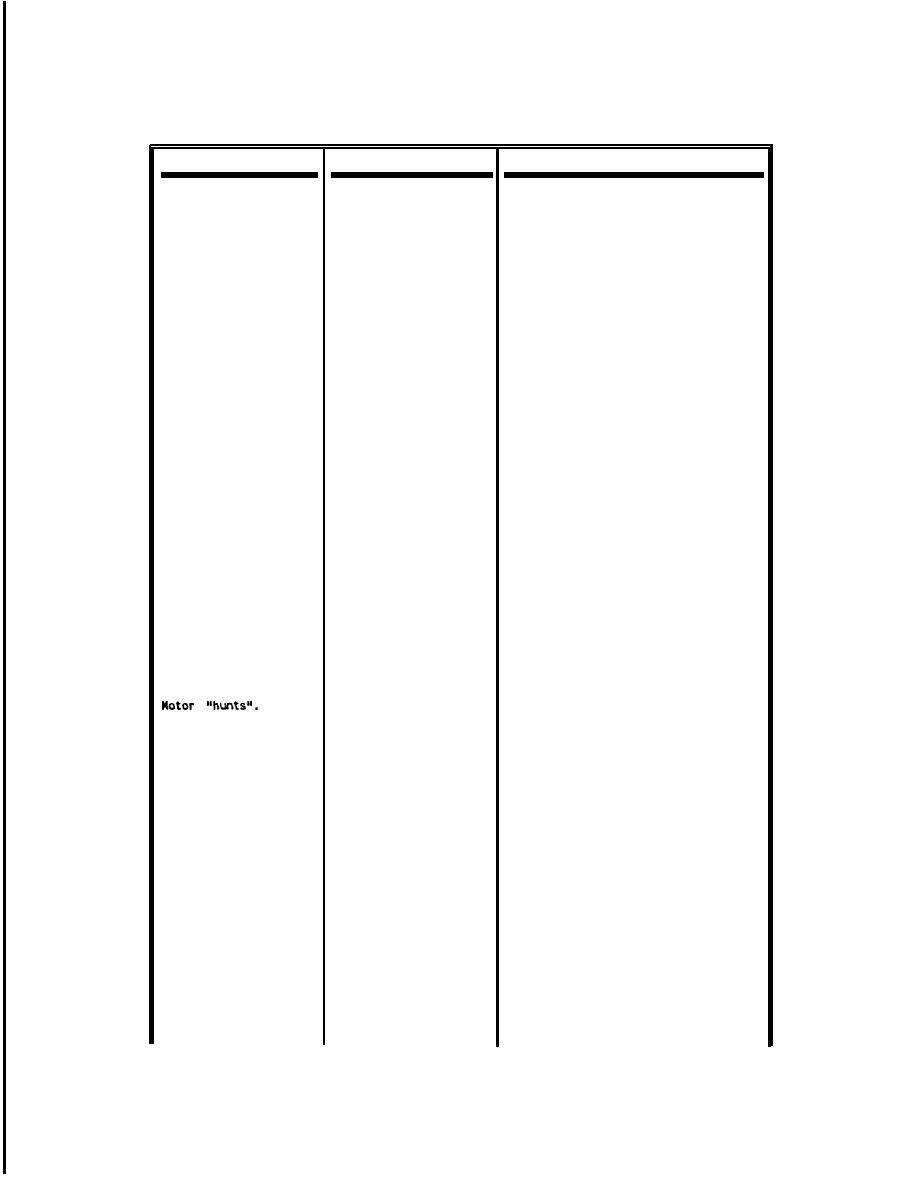

Table 4-3. AC induction motor trouble-shooting-continued.

Maintenance

Probable Cause

Trouble

Reduce load

Fails to pull into

Load excessive

step (cont'd).

Check operation of loading

device (if any) on driven machine.

- consult

May be a misapplication

Inertia of load

excessive.

manufacturer.

Increase excitation.

Exciter voltage low.

Motor pulls

out of

step or trips

Examine exciter as shown in D. C.

breaker.

Check field ammeter and

motors.

its shunt to be sure reading is

not higher than actual current.

Locate and repair break.

Open circuit in field

and exciter circuit.

Check with low voltage and

Short circuit in

p o l a r i t y indicator a n d r e p a i r

field.

field.

spool.

Check with lO w voltage and

Reversed field

polarity indicator and reverse

incorrect leads.

See motor "hunts",

below.

Load fluctuates

widely.

Check driven machine for bad

Excessive torque

or consult motor

adjustment,

peak.

manufacturer.

Re-establish power circuit.

Power fails.

Raise

Increase if possible.

Line voltage too low.

excitation.

Correct excessive torque peak at

Fluctuating load.

driven machine or consult rotor

manufacturer.

If driven machine is a compressor

check valve operations.

Increase or decrease flywheel

size.

Try decreasing or increasing motor

field current.

Realign and shim stator or

in

Rotor not centered.

Stator overheats

spots .

Check connections and correct.

Open phase.

improper

Loose connections;

Unbalanced

internal connections.

Replace or repair.

Short circuit in a

Field overheats.

field coil.

Reduce excitation until field

Excessive field

current is at nameplate value.

current.

4-31

|

|

|

|

||