Custom Search

|

|

|

||

TM 5-683/NAVFAC MO-116/AFJMAN 32-1083

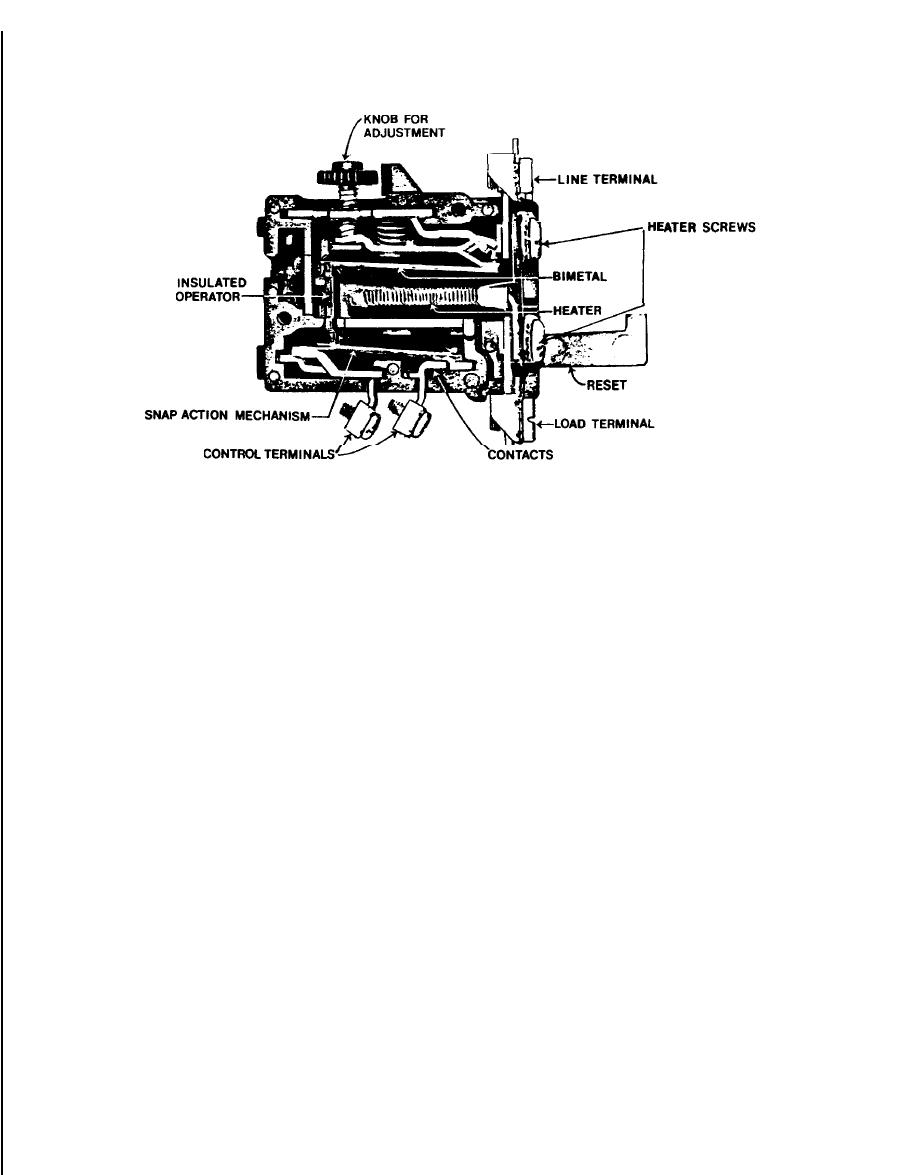

Figure 5-14. Typical terminal overload.

should be replaced to avoid possible misalignment

controller and motor should be located in the same

of an old contact with a new one. Check the contact

ambient temperature environment so that the over-

spring pressure with a scale in accordance with the

load relay can act accurately. If the controller is

manufacturer's recommendations. Adjust or replace

located in a lower ambient temperature environ-

the springs as necessary to maintain good pressure

ment than the motor, it may not trip in time to

between pairs of contacts. When copper contacts

protect the motor. Vice versa, if the controller is in a

become excessively rough, they should be smoothed

higher ambient temperature than the motor, it will

with a burnishing tool or a fine file designed for this

trip even if the motor is not in overload. The signifi-

purpose. Do not use emery cloth. Also, any copper

cant different ambient temperatures of the motor

oxide on the contact surfaces should be removed.

and controller can be compensated by selection of a

Copper oxide is not sufficiently conductive, it acts as

relay heater or use of a relay that compensates for

a high resistance and could eventually cause over-

temperature. The adjustments are to decrease the

heating. When filing, particular care should be

motor current protection (lower trip setting) by one

taken to maintain the original shape of the contacts.

percent for each degree Celsius the motor ambient

It is not necessary to develop smooth contact sur-

exceeds the controller normal ambient temperature

faces. In fact, better operation is obtained when the

or increase the motor current protection (raise trip

surfaces are rough dressed. Contacts should not be

setting) by one percent for each degree Celsius the

lubricated.

controller ambient exceeds the motor ambient. The

manufacturer's published heater selection tables

(2) Silver contacts. Silver contacts should not

be filed. Silver oxide, that forms on the contact sur-

should be referenced (fig 5-15). It should be noted

faces, does not have to be removed because it is a

that in this case, according to the National Electri-

cal Code, a disconnecting means must be located in

good conductor. Routine inspection should always

include checks for tightness of terminal and cable

sight from the controller location.

connections as well as for signs of overheating. Re-

f. Contractors. The part of the starter that con-

tains the coil and contacts is known as the contactor

placements should be made as conditions dictate.

Manufacturer's recommendations should be fol-

(fig 5-16). It is used to control the circuits to the

motor. Contractors are intended for repetitive opera-

lowed closely for maintenance and replacement of

tion, perhaps as many as a million or more opera-

parts.

tions. Normal wear and tear can be expected, and

(3) Shunts. Shunts are flexible bands of woven

therefore periodic inspections should be made to

copper strands carrying current from the moving

ensure that all moving parts are functioning. prop-

contacts to a stationary stud. If the shunt is unduly

erly.

bent or strands are broken, then it should be re-

placed.

(1) Copper contacts. Copper contacts should be

replaced when worn thin or badly burned and pit-

(4) Coils. Coils require very little maintenance.

ted. Both the moving and the stationary contacts

In fact it is generally more economical to replace the

5-14

|

|

|

|

||