Custom Search

|

|

|

||

TM 5-684/NAVFAC MO-200/AFJMAN 32-1082

mendations listed herein, it is good practice to de-

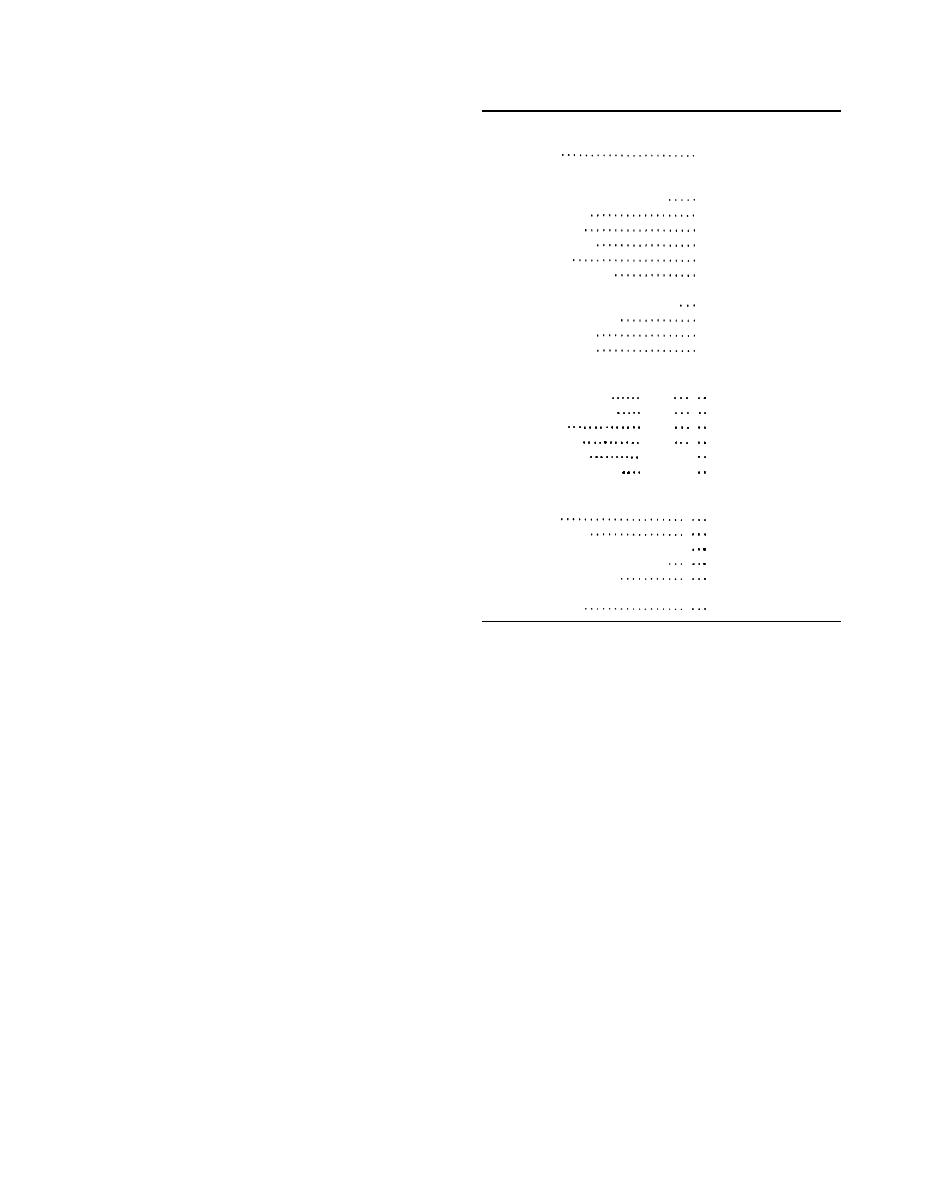

Table 7-l. Transformer inspection and maintenance checklist

velop a habit of visual inspection whenever a

General inspection items

transformer area is visited. In this way leaks,

Load current

Weekly or monthly

cracked insulators, loose connections, and similar

Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weekly or monthly

problems may be noticed before serious problems

Temperature . . . . . . . . . . . . . . . . . . . . . . . .

Weekly or monthly

develop that might affect the continuity of service.

Liquid level or pressure vacuum

Weekly or monthly

When working around a transformer, particular

Protective devices.

Annually

care must be taken in handling all tools and other

Protective alarms

Monthly

Ground connections

Every 6 months

loose articles, since material dropped into the wind-

Surge arresters

Every 6 months

ings and allowed to remain can cause a breakdown.

Pressure-relief devices.

Every 3 months

a. Power transformers. For maintenance pur-

Breather . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monthly

poses consider the impact that the loss of a power

Auxiliary equipment and bushings

Annually

transformer will have on the facilities operation.

Load tap changer (LTC)

Annually

External inspection

Every 6 months

Utility-facility interconnection transformers and

Internal Inspection.

From 3 to 6 years

transformers with medium-voltage secondary lines

can be defined as significant impact transformers,

Solid insulation (winding)

while other power transformers can be considered

Insulation resistance.

Annually

as less significant impact transformers. There may

Polarization index (PI)

Annually

be slightly different maintenance techniques for liq-

Power factor.

From 3 to 6 years

Hi-pot (ac or dc)

From 3 to 6 years

uid and dry-type transformers, but the general ap-

Induced potential

From 3 to 6 years

proach is the same.

Transformer turns ratio

Annually

(1) Significant impact transformers. Table 7-l

Insulating liquid

is a recommended inspection and maintenance

checklist based on input from NFPA, NETA, and

Gas analysis.

Annually

manufacturer's published guides. For transformers

Dielectric strength

Annually

Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Annually

having a less significant impact, checking should be

Acidity (neutralization number).

Annually

decreased as covered later.

Interfacial tension (IFT)

From 3 to 6 years

(2) Less significant impact transformers.

General inspection items

Power factor test.

From 3 to 6 years

Transformer readings should include load current

at peak load, voltage readings during both peak-

load and low-load periods, temperature, liquid level,

clamp-on ammeter. Reasonable accuracy and com-

and pressure/vacuum recordings. These readings

plete safety should be of the greatest importance in

should be taken not less than every 6 months along

making transformer load surveys. Readings should

with general inspection tests from table 7-l that

be taken on the secondary side of the transformer

are not annual or 3-to-6 year tests. Other tests of

whenever possible. Testing all transformers may

table 7-l may be needed dependent upon the re-

not be necessary, because similar areas and build-

sults of the 6-months' tests.

ings may have quite similar loads.

b. Distribution transformers. Porcelain bushings

(2) Dielectric tests. Dielectric tests of liquid -

should be kept clean and the transformers in-

immersed transformers need not be made on distri-

spected annually. Check for broken porcelain, loose

bution transformers of less than l00-kVA capacity.

power connections, blown fuses, and defective surge

Liquid samples should be taken at 5-year intervals

arresters. Check for leaks, hardened bushing gas-

from each liquid-immersed distribution transformer

kets, corroded or broken ground connections, rust-

of 100-kVA and greater capacity. These samples

ing of tanks, and signs of corrosion on terminals,

should be given a dielectric test. If a liquid-

bushing studs, and connectors. If the transformer is

immersed transformer has been out of service for

excessively noisy or has a ruptured gasket, then the

one year or more, dielectrically test a liquid sample

unit should be opened, internally inspected, and

from that unit before re-energizing the transformer.

tested.

When a liquid sample fails to meet the dielectric

(1) Load test. A load test should be made annu-

standard, filter the liquid until it meets the stan-

ally on transformers which supply a load that is

dard or replace with new liquid of a type and grade

known to be increasing. Transformers which supply

recommended by the transformer manufacturer.

a steady connected load should be load tested every

5 years. Load tests should be made with portable

7-5. Transformer inspections.

ammeters (dial-indicating or recording-chart type),

installed for at least 24 hours on a peak loading

Inspection and repair will vary dependent upon the

period day as determined by spot checking with a

type of transformer installed. Always expand or

7-3

|

|

|

|

||