Custom Search

|

|

|

||

TM 5-684/NAVFAC MO-200/AFJMAN 32-1082

a. Insulation resistance test. Routine insula-

by overheating, and tracking and carbonization.

Look for cracked or chipped insulators; loose insula-

tion resistance tests on transformers are normally

tors, clamps, or coil spacers; deterioration of barri-

made at voltages given in table 3-4. Insulation

ers; and corroded or loose electrical connections.

resistance usually decreases somewhat with an

(13) Cleaning and other dry-type transformer

increase in applied voltage. However, for a varia-

requirements. Dirt and dust should be removed from

tion of two to one or three to one in the usual test

the windings with a vacuum cleaner. Compressed

voltage ranges, there is no appreciable effect on

air may be used after vacuuming, but only if it is

insulation resistance for equipment that is in

clean and dry and applied at a low pressure to avoid

good condition. Marked variations in insulation

damage to windings. In particular, ventilating ducts

resistance for different values of voltage are usually

and the top and bottom of the windings should be

due to the effects of dirt or moisture. The insula-

cleaned. The use of liquid cleaners should be em-

tion resistance values for oil-filled transformers

ployed only when it is known that they will not have

will vary due to humidity, size and type of trans-

a deteriorating effect on the insulation.

former, temperature, and the value the test voltage

(a) Operation. Best service life will result if

applied.

the windings are maintained above the ambient

(1) Records. A record should be made of all

temperature level. For this reason, transformers op-

factors for comparison with previous and future test

erating in high humidity should be kept energized,

results. Temperature correction factors are indi-

if feasible. If a transformer is to be de-energized

cated in table 7-2. To obtain the equivalent insula-

long enough for it to cool, special drying procedures

tion resistance at 20 degrees C, multiply the insula-

may be required before the transformer is re-

tion resistance reading in megohms by the

energized. Refer to the manufacturer's recommen-

appropriate correction factor. Values of winding in-

dations for drying procedures to be followed.

sulation resistance may be affected by residual

(b) Sealing. Sealing severe leaks, or opening

charges that are retained in the winding. For this

and resealing the tanks of sealed dry-type trans-

reason, windings should be discharged to the frame

formers, requires special procedures and equip-

until the discharge current reaches a negligible

ment. The manufacturer of the transformer, an ex-

value. Ten minutes or more may be required to

perienced transformer repair facility, or a qualified

complete the discharge.

electrical maintenance contractor should perform

(2) Insulation testers. Resistance testers are

this work.

available that indicate directly in ohms the resis-

(c) Special procedures. In addition, special

tance being measured. The power source necessary

procedures covering drying out of the windings, and

for operation of the tester may be a hand cranked

purging and refilling of the tank, may be required.

generator, motor operated generator, or rectifier

7-6. Transformer testing guidance.

supplying a direct-current voltage for test purposes.

For best results, the detailed instructions furnished

All tests should meet the requirements of

with each of these instruments should be followed.

ANSI/IEEE CF57.12.90 for liquid-immersed trans-

formers and IEEE (X7.12.91 for dry-type trans-

formers. Expanded explanatory data for tests can

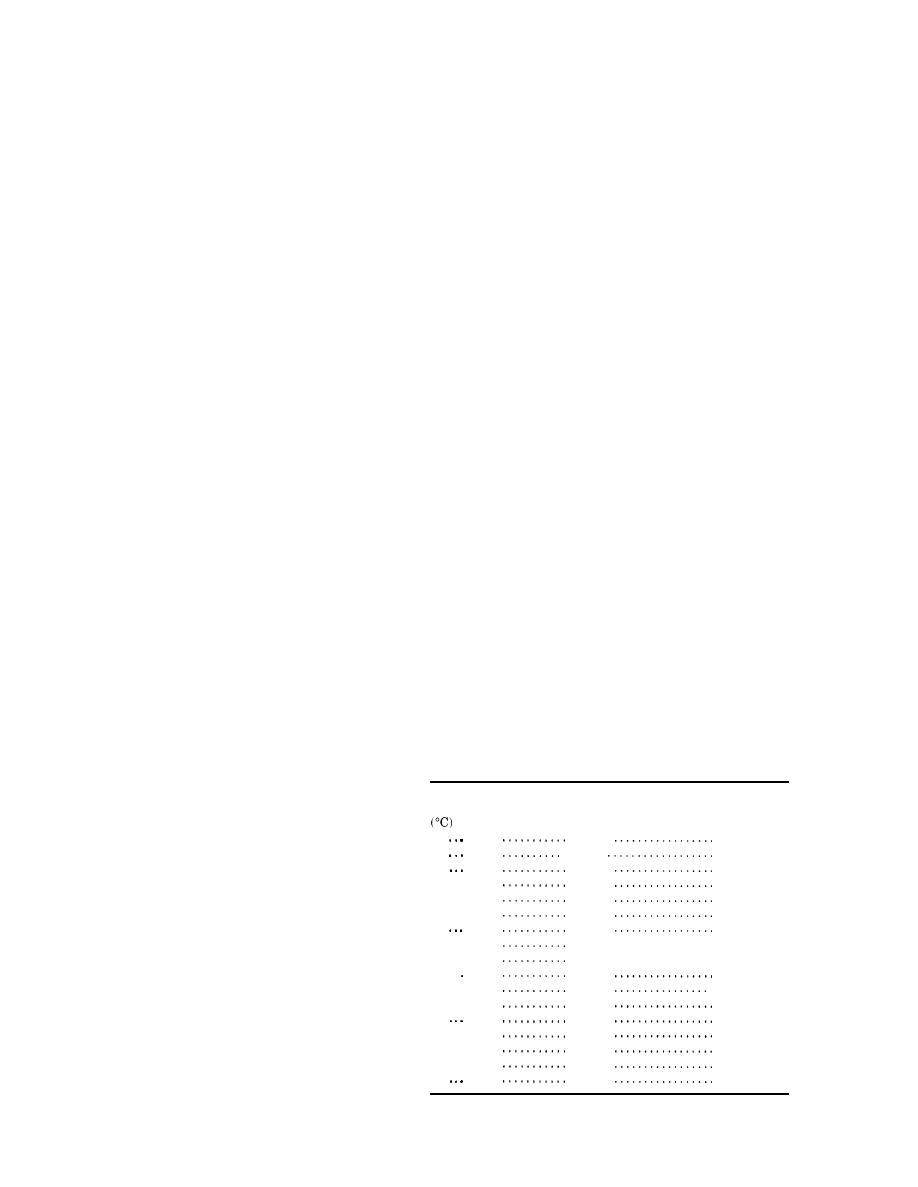

Table 7-2. Insulation resistance conversion factors to 20C

also be found in NFPA 70B and "Electrical Equip-

Temperature

Transformer

ment Testing and Maintenance."

Oil

Dry

7-7. Solid (winding) insulation tests.

0.25

0

0.40

0.45

5

0.36.

Nondestructive tests for the dielectric properties of

10

0.50

0.50

solid insulation include the insulation resistance

15 . . .

0.75

0.75

test, the dielectric-absorption test, and the power

20 . . .

1.00

1.00

factor test. High potential and induced potential

25 . . .

1.30

1.40

tests can cause damage to the insulation. However,

30

1.60

1.98

35 . . .

2.80 . . . . . . . . . . . . . . . . .

these tests do discover weakened insulation, and

2.05

40 . . .

2.50

3.95 . . . . . . . . . . . . . . . . .

any damage is usually much less than that caused

45 . .

5.60

3.25

by an in-service failure. Insulation tests can be ap-

50 . . .

7.85

4.00

plied to dry-type transformers; however, the voltage

55 . . .

5.20

11.20.

impulse values should be lower than those used for

60

6.40

15.85

65 . . .

22.40

liquid-immersed transformers. A transformer turns

8.70

70 . . .

31.75

10.00

ratio test can identify trouble in transformer wind-

75 . . .

44.70

13.00

ings; its use in proof testing is generally limited to

80

63.50

16.00

dry-type units.

7-6

|

|

|

|

||