Custom Search

|

|

|

||

TM 5-684/NAVFAC MO-200/AFJMAN 32-1082

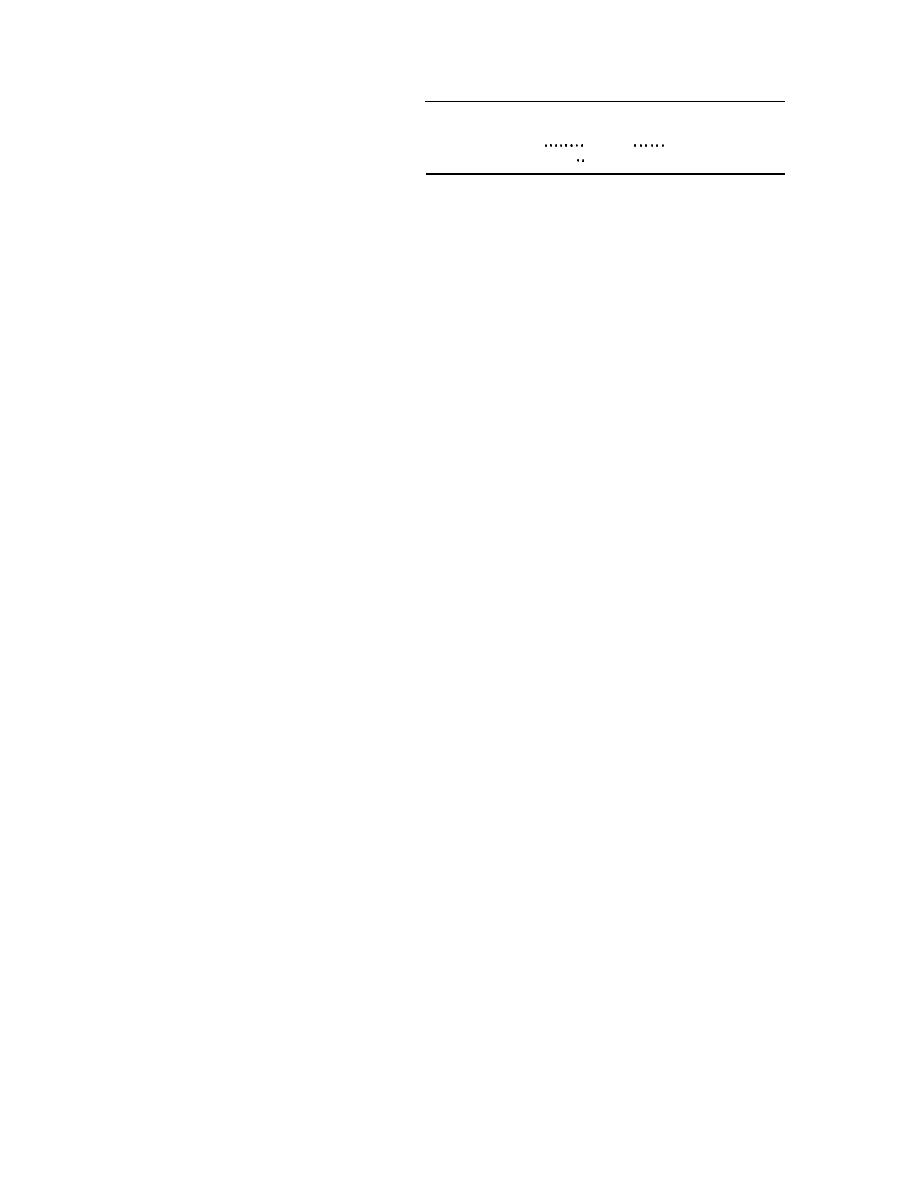

Table 7-3. Satisfactory power factors

d. Type of tests. Annual, comprehensive, and dis-

solved oil-in-gas tests are made on liquid insulation.

Mineral oil

RTemp Silicone

ANSI/IEEE C57.106 and ASTM D 117 cover accep-

Power transformers

0.005

0.005

0.005

tance, maintenance, and test requirements.

Distribution transformers

0.01. . . . . . . .

0.0 1

0.005

(1) Annual tests. Annual tests determine

whether the insulating liquid is in satisfactory con-

(3) Dissolved gas-in-oil tests. ASTM D 3612

dition or whether more comprehensive tests should

be made.

covers this test which analyzes the combustible gas

(a) Dielectric breakdown. The dielectric

liberated by normal use of insulating liquid. The

breakdown voltage test is covered in ASTM D 877.

dissolved gases are extracted from an oil sample. A

The minimum acceptable breakdown values are 22

portion of the gases are then subjected to chromato-

kV for oil and 26 kV for RTemp and silicone.

graphic analysis. This analysis determines the ex-

(b) Acidity. The acidity test is covered in

act gases present and the amount of each. Different

ASTM D 1534. This test indicates how much the oil

types of incipient faults have different patterns of

has oxidized. The maximum permissible neutraliza-

gas evolution. With this test the nature of the prob-

tion number is 0.4 for oil, 0.5 for RTemp, and 0.01

lems can often be diagnosed, utilizing data from

for silicone.

IEEE 104.

(c) Color. The color test is covered in ASTM D

e. Reconditioning and replacement of insulating

Liquids. If any of the tests indicate that an insulat-

1524. New oil is clear, while a dark oil indicates

contamination. The maximum acceptable "color

ing liquid is not in satisfactory condition, it may be

number" is 4 for oil and 1.5 for RTemp.

restored by reconditioning, reclaiming, or it can be

(2) Comprehensive tests. Comprehensive tests

completely replaced. Reconditioning is the removal

include a power factor test using an ASTM D 924

of moisture and solid materials by mechanical

test cell, and an interfacial tension (IFT) test in

means such as filter presses, centrifuges, or vacuum

dehydrators. Reclaiming is the removal of acidic

accordance with ASTM D 971 or ASTM D 2285. A

liquid at 20 degrees C, with a power factor as given

and colloidal contaminants, and products of oxida-

tion, by chemical and absorbent means. These in-

in table 7-3, is considered satisfactory. If the value

is above 0.5 percent investigate. If the value is

clude processes involving Fuller's earth, either

alone or in combination with other substances. Re-

above 2 percent, replace or recondition. The IFT will

vary dependent upon the liquid used, but values

placing the liquid involves draining, flushing, test-

ing, and proper disposal of materials removed. It is

below 40 dynes per centimeter for oil, 30 dynes per

centimeter for RTemp, and 21 dynes per centimeter

recommended that these procedures be done by con-

tract personnel who have the necessary experience

for silicone probably indicate that reconditioning is

advisable.

and equipment.

7-8

|

|

|

|

||