Custom Search

|

|

|

||

TM 5-684/NAVFAC MO-200/AFJMAN 32-1082

Table 11-l. Typical laboratory relay test equipment

115 VOLTS. 60 HZ

Test equipment

Description

115 volt, 5 and 15-20 amperes

Variable voltage

autotransformer

3-15-150 volt, 5000 ohms

Multirange dc voltmeter.

0-2-5-l0-20-50-100-200 am-

Multirange ac ammeter

peres

0-3-7.5-30-75-150-300 volts

Multirange dc voltmeter.

0-5-20-50-amperes

Multirange dc ammeter

5-10-30 amperes, 15-30-50-

Phase angle meter

120-240-480 volts, 60 hertz

Auxiliary current transformers 1-5-10-25-50-62.5-125-250-

500/5 amperes

Cycle counter or timer.

0 - 1 0 seconds, 120 volts

RELAY

three-phase, 500 watts

Phase shifter

Multirange noninductive load

0-100 amperes range

resistor

R

Three-phase sequence indica-

110-550 volts, 25-60 hertz

tor..........................

Auxiliary relays, dc

125 volt

satisfactory, provided the shaft or bearings have not

been disturbed. In any case, the manufacturer's di-

rections should be followed.

e. Performance check. Upon completion of repair

work, complete performance tests should be made

on the relay, even though the work done may not

appear to affect relay operation. It is possible that

during repair, other adjustments or alignment of

relay parts may have been changed or affected. Af-

ter an overhaul, the tests made should not be less

thorough than the relay's original acceptance tests.

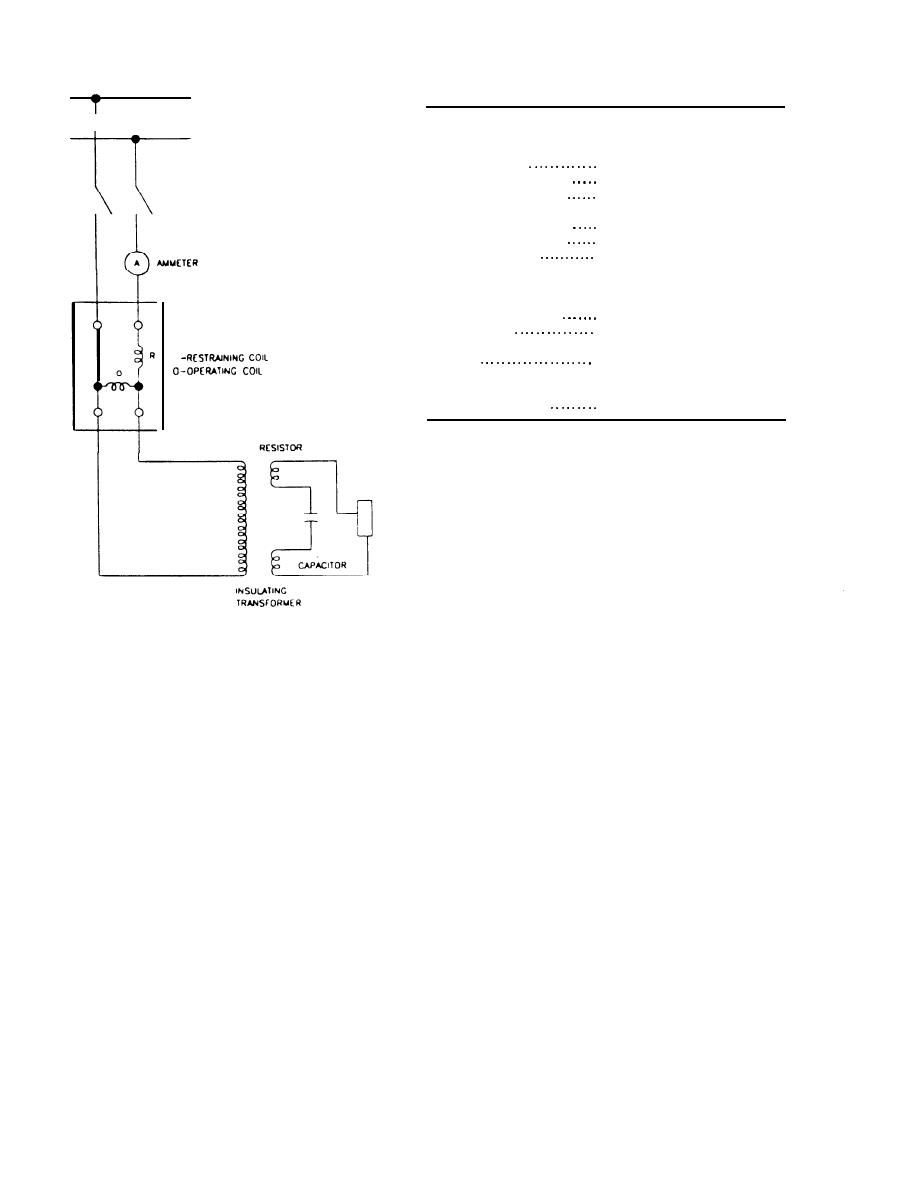

Figure 11-5. Typical test connection for a pilot wire relay

Section II-CONTROLS

11-10. Control functions.

much greater degree by ambient temperature

changes and excessive electrical circuit parameters.

Controls are broadly defined as the methods and

b. Power supply. Control equipment may be pow-

means of governing the performance of any electric

ered from storage batteries or from an ac source.

apparatus, machine, or system, by sensing any need

Controls will only be as dependable as their operat-

for a change and facilitating that change. In per-

ing input. The power supply must be as reliable as

forming these duties, control circuits or systems

possible, so that control and protection of the equip-

may act to regulate, protect, indicate, open, close, or

time an operation. Control devices execute control

ment is not jeopardized. See chapter 14 for details of

functions.

battery maintenance and repair.

a. Control equipment. Some of the more common

c. Control lines. Pneumatic and electromagnetic

equipment controlled are switches, circuit breakers,

controls are gradually being replaced by electronic

contactors, lights, rheostats, timers, and valves.

loop controls, as systems are increasingly being in-

Control schemes use combinations of the following

corporated into energy management control sys-

component parts to produce the desired operation:

tems (EMCS) or supervisory control and data acqui-

alarms, batteries, coils, fuses, relays, solenoids, tim-

sition systems (SCADA). Sensors are used to

ers, switches, and transformers. Other special elec-

provide units of information via conventional (hard)

trical equipment may be used also.

wiring to the field interface devices (FIDs). A sensor

(1) Electromechanical controls. Electrome-

is installed as a component part of the electrical

chanical controls are operated by magnets, thermal

apparatus being controlled and must be maintained

action, motors, or other mechanical or static actions.

by electrical maintenance personnel. Control line

(2) Solid-stat e controls. Solid-state controls

components such as FIDs, data transmission links,

the central processing unit (CPU) and its subcompo-

perform similar functions to electromechanical con-

nents are not electrical maintenance responsibili-

trols, but their characteristics are affected to a

11-6

|

|

|

|

||