Custom Search

|

|

|

||

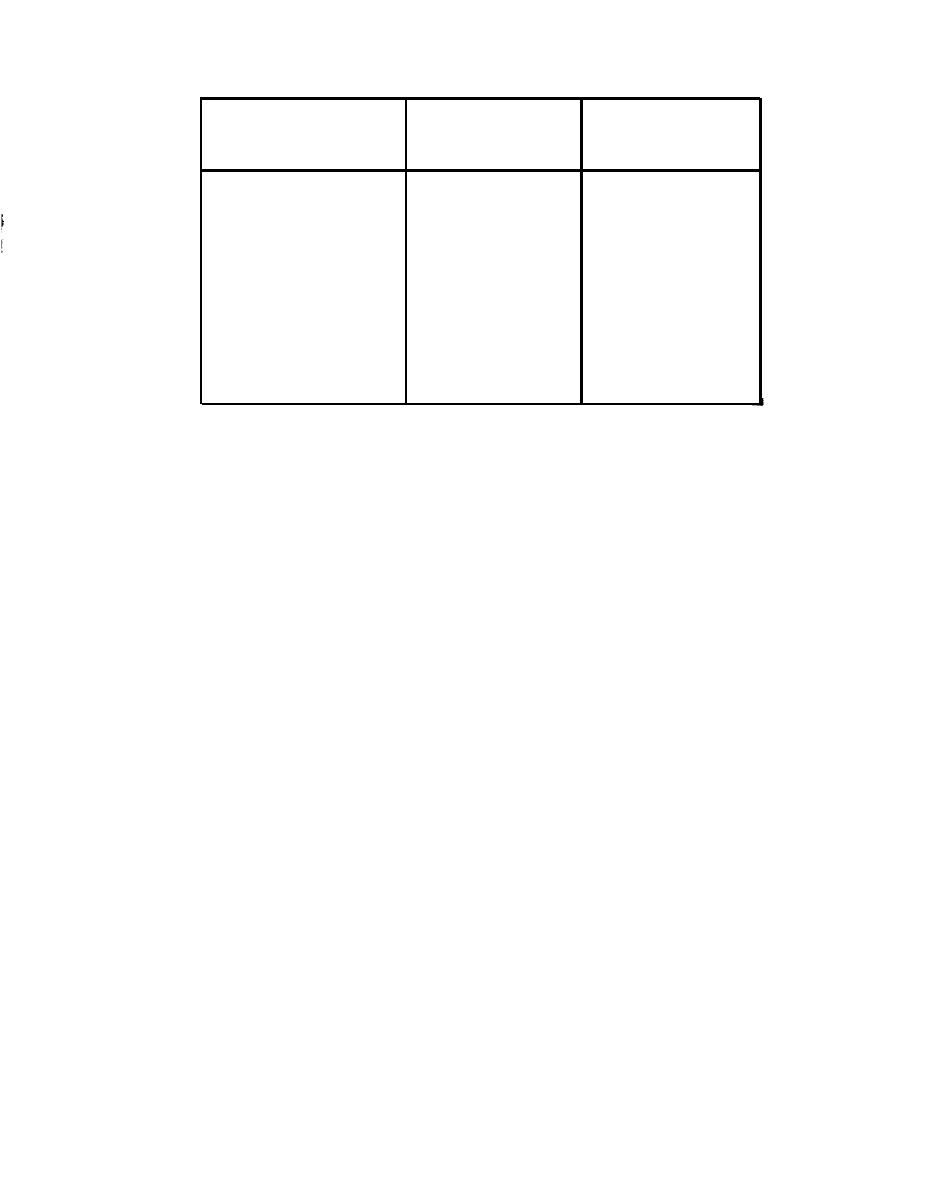

TABLE l-l. Maximum Pressures and Capacities of Air Compressors

Compressor

Maximum Pressure

Maximum Capacity

Type

(cfm)

(psig)

26,000

Reciprocating

100,000

6,000

Rotary sliding vane

400

32,800

Rotary twin-lobe

20

16,000

Rotary liquid piston

100

650,000

Centrifugal

5,500

1,000,000

Axial

500

removing moisture and oil from the compressed air. Refer to chapter 4,

section 3.

3.4 Separators. Separators remove and collect entrained water and oil

precipitated from the air. Refer to chapter 4, section 4.

3 . 5 Traps.Traps drain condensed moisture and oil from separators,

intercoolers, aftercoolers, receivers, and distribution piping. Refer to

chapter 4, section 5.

3.6 Air Receivers. Air receivers are tanks wherein compressed air is

discharged and stored. They help to reduce pulsations in the discharge line

and provide storage capacity to meet peak demands exceeding the capacity of

the compressor. Refer to chapter 4, section 6.

3.7 Air Dryers. Air dryers remove moisture that might condense in air lines,

air tools, or pneumatic instruments. Refer to chapter 4, section 7.

3.8 Safety Valves. Safety valves are used in a compressed air or gas

system. They must open rapidly and fully so that excessive pressure buildup

can be relieved immediately to prevent damage or destruction of the system

components. Although the terms safety valve and relief valve are often used

liquid systems. Since liquids are virtually incompressible, a relief valve is

designed to open gradually as the venting of a small amount of liquid is often

sufficient to relieve excessive pressure throughout the system. There is one

class of valve known as a safety-relief valve that can be used as either type

depending upon internal adjustments. Safety valves are found in interstages,

air receivers, and between a positive displacement compressor and any shutoff

valve.

4 CONTROLS. Control systems for air compressors vary from the relatively

simple to the extremely sophisticated. The simpler control systems, through

the use of sensors, monitor the performance of the equipment and, through the

l-3

|

|

|

|

||