Custom Search

|

|

|

||

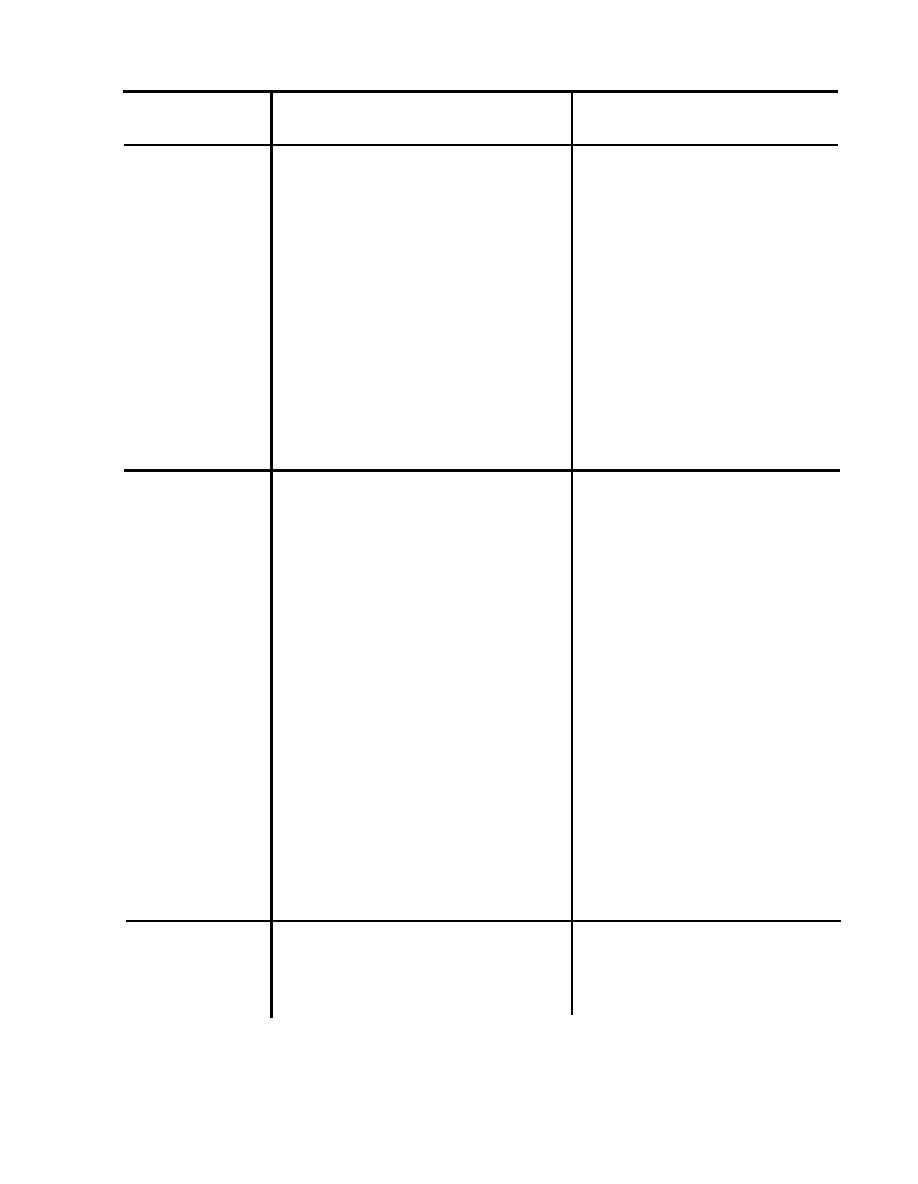

TABLE l-2. Troubleshooting Chart (Continued)

Remedy

Possible Cause

Problem

Correct oil level.

Lubrication inadequate.

Oveheating of

Correct oil pressure.

parts

(continued)

Ensure correct oil

viscosity is being used.

Ambient temperature too high.

Lower ambient temperature.

Increase ventilation.

Clean valves.

Valves dirty.

Readjust belt tension.

Belts too tight.

Readjust packings.

Packings too tight.

Stop leaks.

Delivery of air

System leaks excessive.

less than

Clean or replace filter as

rated capacity

Intake filter clogged.

applicable.

Replace worn or broken

Valves worn or broken.

valves.

Tighten.

Belts slipping.

Increase speed.

Speed lower than rating.

Compressor components worn or

Replace.

broken.

Control device inoperative or

Repair or adjust control

device.

maladjusted.

Increase water quantity.

Water quantity insufficient.

Inlet temperature too high.

Check water quantity and

temperature at inter-

cooler.

Excessive

Mounting bolts loose.

Tighten mounting bolts.

vibration of

l-9

|

|

|

|

||