Custom Search

|

|

|

||

8.6 Bearings. Sleeve type main bearings are adjusted by removing or adding

metal shims between the cap and body of the bearing housing. The same number

of shims should be added or removed from each side of the bearing. Make sure

caps are tightly secured so they cannot work loose. Do not overtighten as

this causes overheating of the bearing. Consult the manufacturer's

instructions for adjustment of tapered roller main bearings.

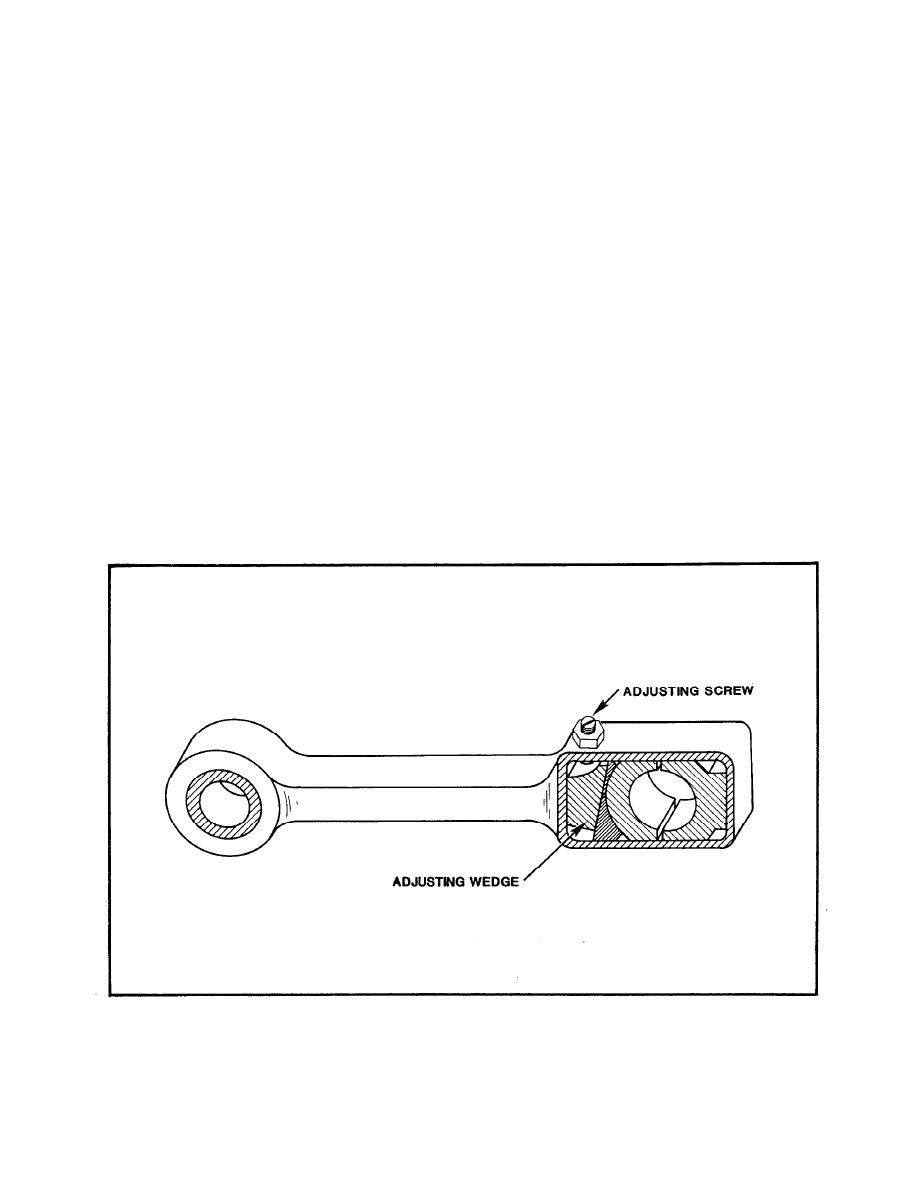

8.6.1 Horizontal Compressor Bearings. Many horizontal compressors have wedge

adjusting crosshead and crankpin bearings (figure 2-3). Adjustment is made by

tightening or loosening the adjusting screws. Do not overtighten the

bearings. A tight fit at the crosshead bearing causes the crosshead to rock,

damaging the crosshead guides and shoes.

8.6.2 Vertical Compressor Bearings. Vertical compressors are usually fitted

with automotive type crankpin bearings with babbitted inserts (figure 2-4).

These bearings are not adjustable and must be replaced. When replacing

bearing inserts or bushings, make sure all parts are thoroughly clean and that

the oil hole is aligned with the oil hole in the connecting rod.

8.7 V-Belt Drives. Adjust tension or replace V-belts as required. When one

or more belts in a set require replacement, replace the entire set with

matched belts. If this is not done, the new unstretched belts, being shorter

than the old belts, will carry most of the load and will be subjected to undue

strain. Removed belts that appear to be in a serviceable condition may be

kept for emergency use.

FIGURE 2-3. Connecting Rod With Wedge Adjusting Bearings

2-10

|

|

|

|

||