Custom Search

|

|

|

||

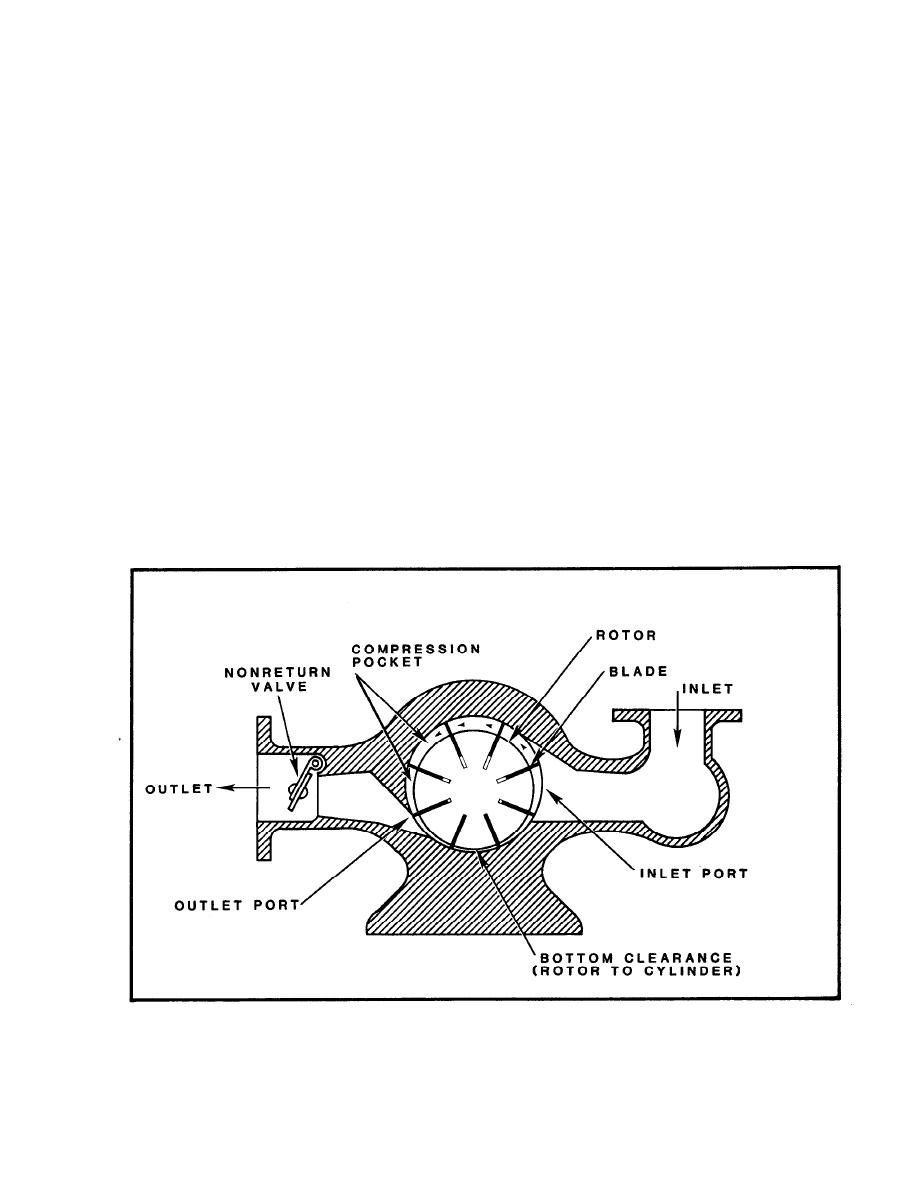

Section 2. ROTARY SLIDING VANE COMPRESSORS

1 DESCRIPTION. Rotary sliding vane compressors (figures 2-6 and 2-7) consist

of a cylindrical casing in which an eccentrically mounted rotor is located.

The rotor is fitted with blades that are free to slide in and out of

longitudinal slots. In operation, the blades are forced outward by

centrifugal force and form compartments where air is compressed. Each

compartment varies from a maximum volume on the suction side of the revolution

to a minimum volume on the compression half of the revolution. This gives a

positive displacement type suction and pressure effect. Rotary sliding vane

machines are normally directly connected to electric motors or internal

combustion engines. Operating and maintenance instructions for electric

motors and internal combustion engines are contained in NAVFAC MO-205, Central

Heating and Steam Electric Generating Plants.

2 STARTUP.

2.1 Prestart Inspection. Carefully inspect the compressor installation to

ensure the following prestart requirements are fulfilled.

(a) All installation and repair work has been completed.

(b) Installation has been cleaned and tested for leaks.

(c) Alignment has been checked.

(d) Unit is properly lubricated; crank lubricator by hand to clear lines

of air and to assure oil supply for startup.

FIGURE 2-6. Cross Section of Rotary Sliding Vane Compressor

2-13

|

|

|

|

||