Custom Search

|

|

|

||

Section 4. SEPARATORS

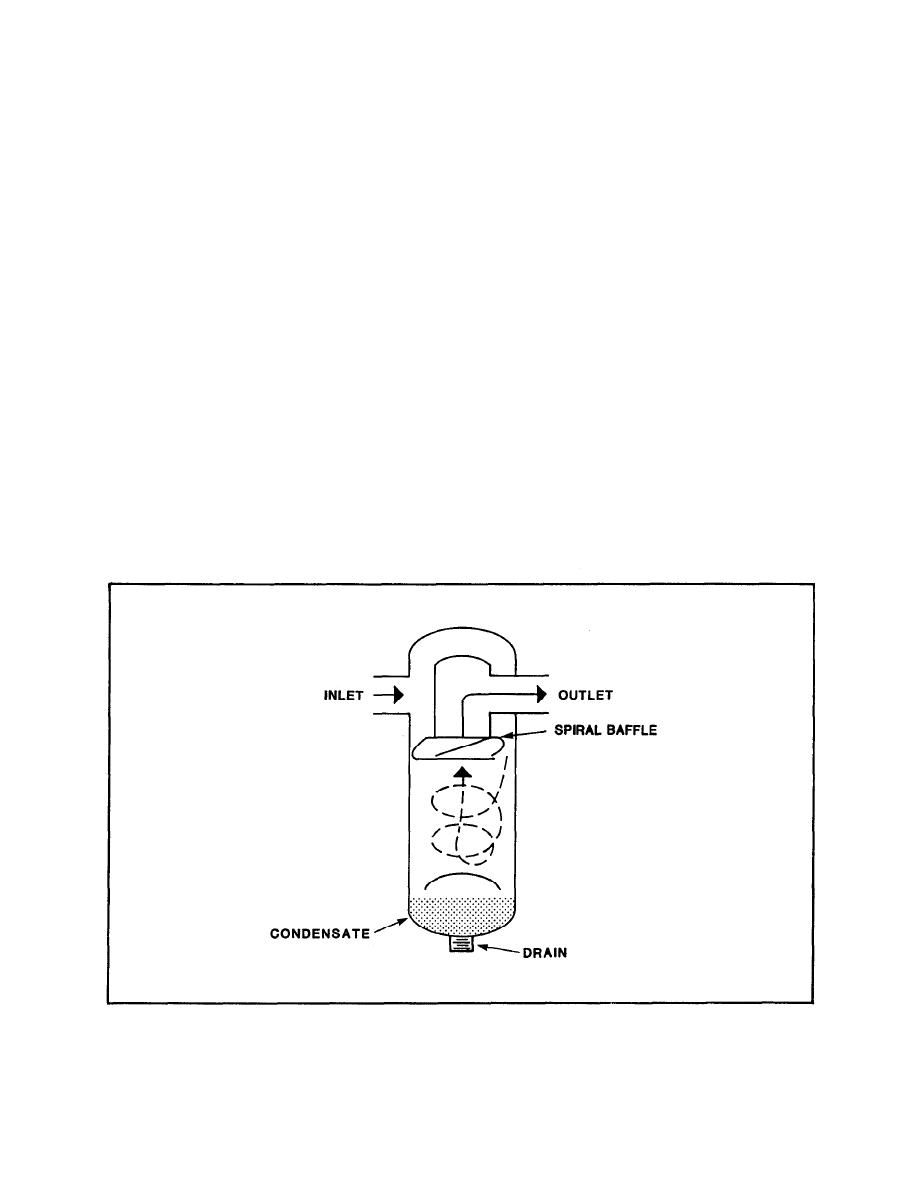

1 DESCRIPTION. Separators are used on compressor installations to remove

entrained water and oil from the compressed air. Figure 4-5 shows a

centrifugal type moisture separator where air is directed into the unit so

that it obtains a swirling motion. Centrifugal action forces the moisture

particles against the wall of the separator where they drain to the bottom.

In the baffle type separator (figure 4-6) the air is subjected to a series of

sudden changes in direction. The heavier moisture particles strike the

baffles and walls of the separator and drain to the bottom of the unit.

2 OPERATION. Drain separators regularly if automatic drainers are not

provided. Frequency of draining is best determined by experience with the

installation. Improperly drained separators result in moisture carryover into

the air distribution system.

3 PREVENTIVE MAINTENANCE INSPECTION. Inspect the separator at periodic

maintenance intervals for the following conditions:

(a) Externally for rust, corrosion and peeling paint

(b) Internally for corrosion and accumulations of dirt and oil

(c) Gaskets for damage

FIGURE 4-5. Centrifugal Type Separator

4-13

|

|

|

|

||