Custom Search

|

|

|

||

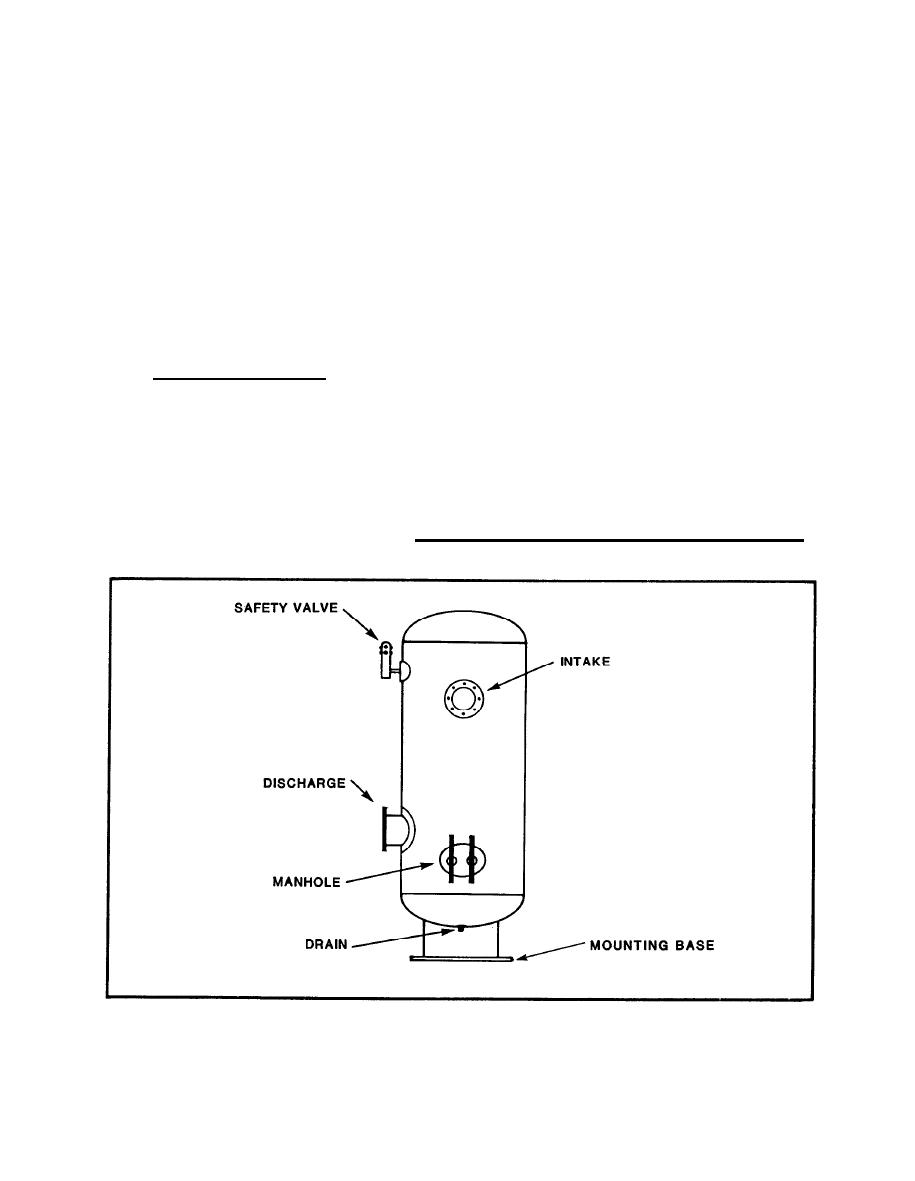

Section 6. AIR RECEIVERS

1 DESCRIPTION. Air receivers (figure 4-8) serve as reservoirs for the

storage of compressed air so that air is available to meet peak demands in

excess of the compressor capacity. They also function as pulsation dampers on

reciprocating compressor installations. Air receivers are usually vertically

mounted, but may be horizontal in the smaller sizes. Receivers are furnished

with a relief valve, pressure gauge, drain valve, and inspection openings.

2 NORMAL OPERATION. Drain receivers of accumulated condensate at least once

each shift if an automatic drainer is not provided.

3 PREVENTIVE MAINTENANCE INSPECTION.

3.1 Daily Inspection. Check automatic drainer for proper operation, if one

is provided.

3.2 Periodic Inspection. Proceed as follows at intervals prescribed by the

manufacturer's maintenance schedule.

(a) Check operation of safety valve.

(b) Examine receiver for corrosion and peeling paint.

(c) Inspect the receiver internally for corrosion and dirt accumulation.

(d) Refer to NAVFAC MO-324, Inspection and Certification of Boilers and

Unfired Pressure Vessels.

FIGURE 4-8. Air Receiver

4-19

|

|

|

|

||