Custom Search

|

|

|

||

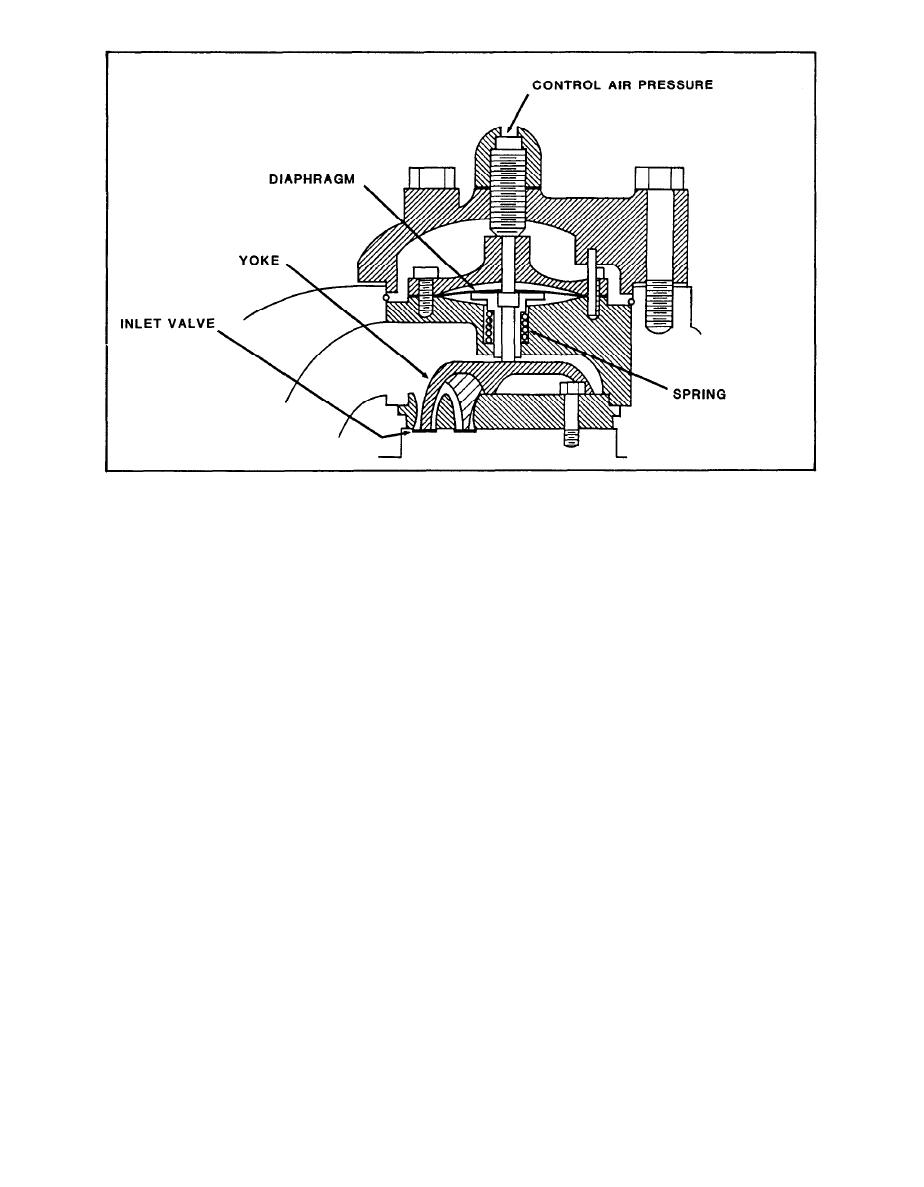

FIGURE 5-3. Inlet Valve Unloader

(2) To understand the operation of this five-step control system

which combines the components previously described, refer to figure 5-4. When

the compressor is started, the air pressure switches are closed and the

solenoids in the unloader valves become energized so that receiver pressure

cannot enter the unloading lines and compression is allowed to take place. As

receiver pressure builds up and reaches 97 psi, APS No. 1 breaks contact,

deenergizing the unloader and allowing 97 psi receiver air to enter control

line No. 1, actuating the inlet valve unloader. Twenty five percent of the

compressor has become unloaded and compression has been reduced from full to

75 percent capacity. Control lines Nos. 2, 3, and 4 operate in the same way

as receiver pressure increases. At 100 psi, all cylinders are unloaded and

air compression ceases, but the compressor continues to run under no load. As

air is drawn off from the receiver, the pressure begins to drop. When the

pressure falls to 96 psi, APS No. 4 makes contact and energizes the unloading

of valve 4, which cuts off receiver pressure from the inlet unloader and vents

the unloader pressure to atmosphere. The inlet valve unloader releases the

inlet valve and normal compression takes place, loading the compressor to 25

percent capacity. If the demand for air increases and receiver pressure

continues to decrease,control lines Nos. 3, 2, and 1 will load in sequence.

5-8

|

|

|

|

||