Custom Search

|

|

|

||

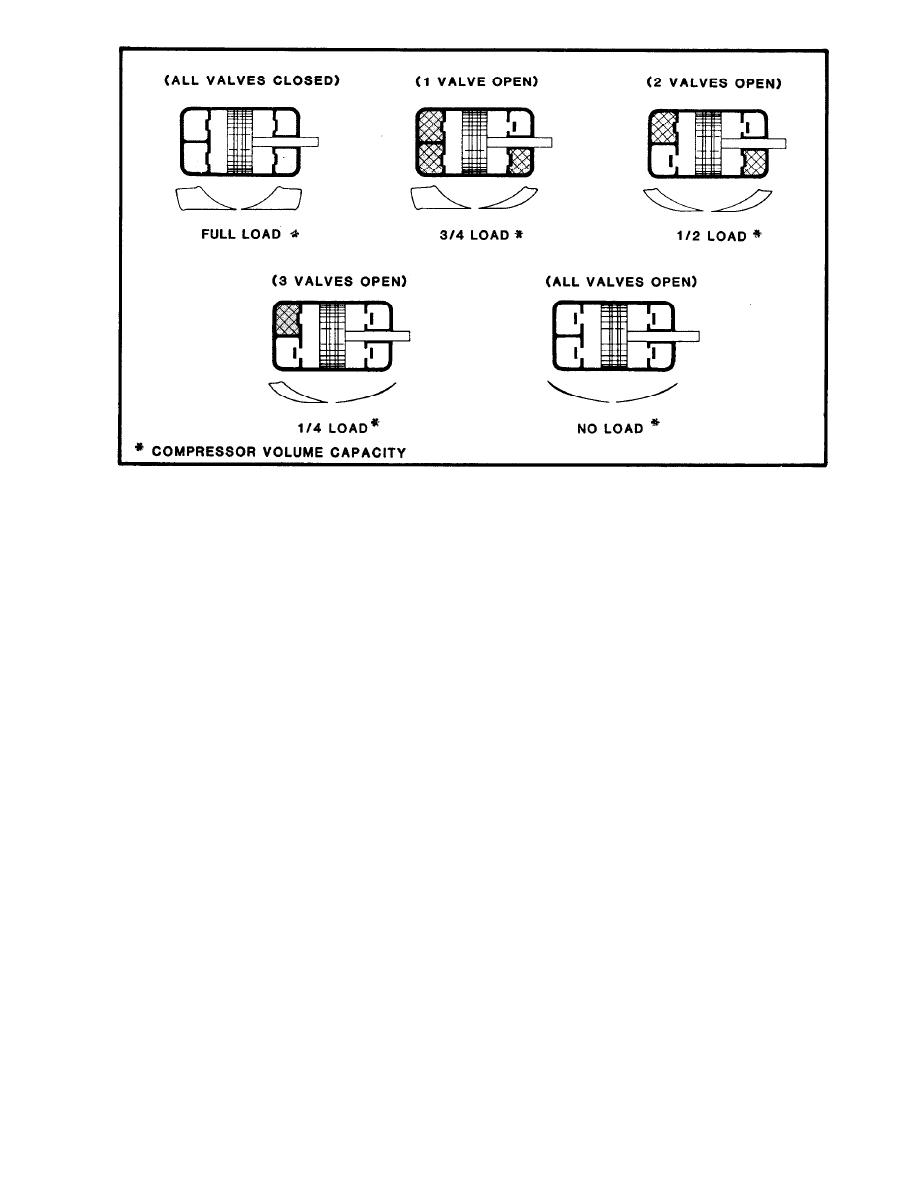

FIGURE 5-6. Five-Step Clearance Control

1.1.2 Centrifugal Compressor. Five methods are generally used to control

1.1.2.1 Inlet Guide Vanes. Centrifugal compressor control may be

accomplished by the use of adjustable inlet guide vanes. The purpose of the

guide vanes is to direct the airflow and distribute it uniformly into the eye

of the impeller. The adjustable vanes located at the first-stage inlet or the

inlet to each stage, are used to modify the pressure-volume characteristics of

the compressor. Guide vanes are manually or automatically adjustable.

1.1.2.2 Blowoff of Output. Blowoff and recirculation are occasionally used

but do not save any power because the compressor is continually operating at

full load pressure and inlet volume. Blowoff relieves excess gas to the

atmosphere, and recirculation puts throttled gas back through the compressor.

1.1.2.3 Intake Throttling. Intake throttling is widely used for control of

constant speed machines. Either inlet butterfly valves or inlet guide vanes

may be automatically or manually controlled. Power conservation is less than

with variable speed, but is still significant.

1.1.2.4 Two-Step Control. Two-step control is mainly useful during load

operations below 50 percent capacity. The amount of flow is dependent upon

two set points. Operation is at full load until the upper set point is

reached, then the unit is unloaded and operates at 15 percent flow until the

lower set point is reached and the system reverts back to full load. The

action is cyclic, maintaining an intermediate pressure value between the set

points. Two-step control is not recommended if a complete load-unload cycle

5-11

|

|

|

|

||